Understanding the Importance of Bearing Clearance

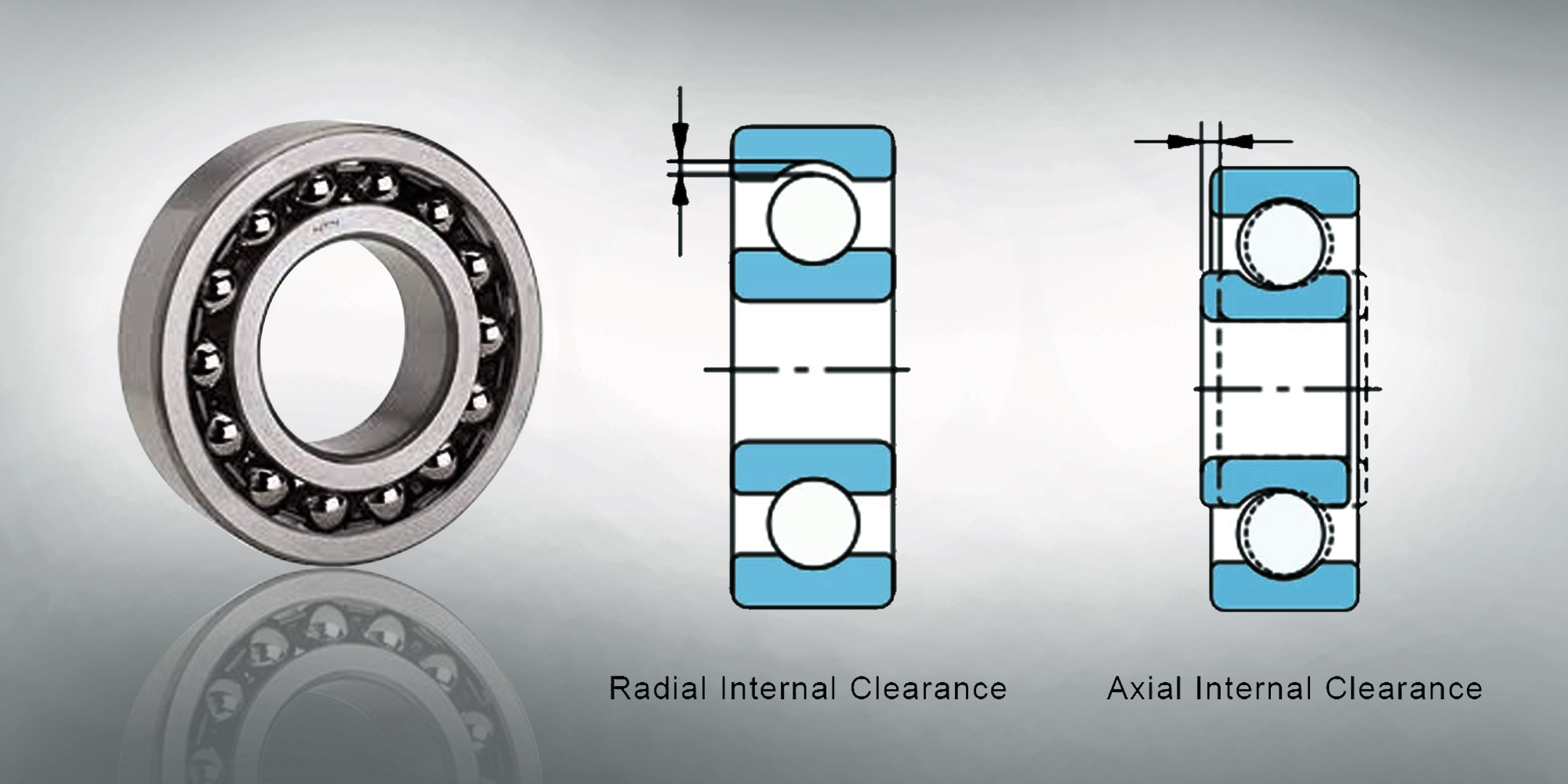

Bearing clearances, whether in ball bearings like the 608 Bearing or roller bearings, play a crucial role in the intricate world of precision...

Bearings are parts that help things move smoothly by supporting rotating or sliding pieces.

They reduce friction between these parts. Their main job is to lower friction and wear. This allows machines to work better and last longer by keeping moving parts stable.

High speed bearings are special parts made to work well at fast speeds while staying precise and stable.

They are highly important in industries like aerospace, automotive, and manufacturing. These bearings help powerful machines run smoothly and effectively.

High speed bearings are specifically engineered to operate at significantly high rotational speeds of 10,000 RPM and beyond.

This design makes them essential for applications that require both precision and reliability. Examples include high-performance motors, turbines, and aerospace systems, where optimal performance and minimal wear are crucial.

Rotational speed (RPM) is an important factor for high speed bearings, but it’s not the only thing that matters.

In other words, factors like design, materials, and lubrication significantly affect the performance and lifespan of bearings. These elements help ensure that the bearings work effectively at high speeds.

Surface velocity refers to the speed at which the bearing's outer surface moves during operation.

The size or diameter of a bearing affects its surface speed.

Larger bearings can achieve higher surface speeds at lower RPMs than smaller ones.

Typically, bearings are considered "high-speed" when their surface velocity exceeds 100 meters per second.

This means that to decide if a bearing is high-speed, you need to look at both its diameter and its RPM. This highlights how important design is for achieving the best performance.

Smaller machines can easily reach speeds of 10,000 RPM or more.

Their components are lightweight and designed for high rotation.

In contrast, larger machinery may not reach such high RPMs because their size and weight.

However, they can still be considered high-speed if their surface velocity exceeds 100 meters per second.

Smaller turbines, like those in gas engines, can easily reach speeds of 10,000 RPM or more. This allows them to work well in tight spaces.

In contrast, large industrial equipment, like wind turbines, may only spin at around 20 to 30 RPM.

However, these large turbines can still achieve high surface speeds of over 100 meters per second. This means they are considered high-speed machines as well.

The rolling elements, such as balls or rollers, are the most crucial parts in determining a bearing's speed capabilities.

They directly impact friction and load distribution. Their shape and size influence how smoothly they roll, which affects the overall efficiency of the bearing at high speeds.

Larger or poorly designed rolling elements can increase friction and heat, limiting the bearing's speed.

In contrast, well-designed rolling parts reduce resistance, allowing the bearing to work well at higher RPMs. This makes them essential for high-speed performance.

Ceramic materials like silicon nitride are widely used in high speed bearings. They are lighter and generate less heat compared to traditional steel.

Silicon nitride is about 40% lighter than steel, which reduces centrifugal forces on the bearing. This allows for smoother and faster rotation with less friction.

Additionally, ceramic materials are better at resisting heat buildup. This minimizes thermal expansion and helps maintain precision even at ultra high speeds.

Low-friction cages and special lubrication help high speed bearings stay cool and last longer.

The low-friction cages keep the balls or rollers spaced out to reduce rubbing.

Meanwhile, air-oil lubrication adds a thin oil layer that prevents excessive contact. This keeps the bearing from overheating and wearing out.

High speed bearings are designed to reduce friction and heat for smooth operation.

Precision manufacturing makes surfaces highly smooth and tight, helping the bearings roll easily.

Lighter materials, such as ceramics, reduce weight, which also decreases friction.

Advanced lubrication systems, like air-oil lubrication, create a thin cooling layer to prevent parts from touching too much.

This helps reduce heat and wear. These features help high speed bearings work efficiently and last longer.

At high RPMs, centrifugal forces push the rolling elements outward, affecting performance.

To handle these forces, the design and materials of the high speed bearings ensure stability and efficiency. This allows them to perform well at high speeds.

Stiffness is crucial for maintaining stability in high speed bearings.

It helps prevent deformation under load and ensures consistent performance.

A stiffer bearing can better support the forces acting on it. This minimizes vibrations and maintains precise alignment of the rolling elements.

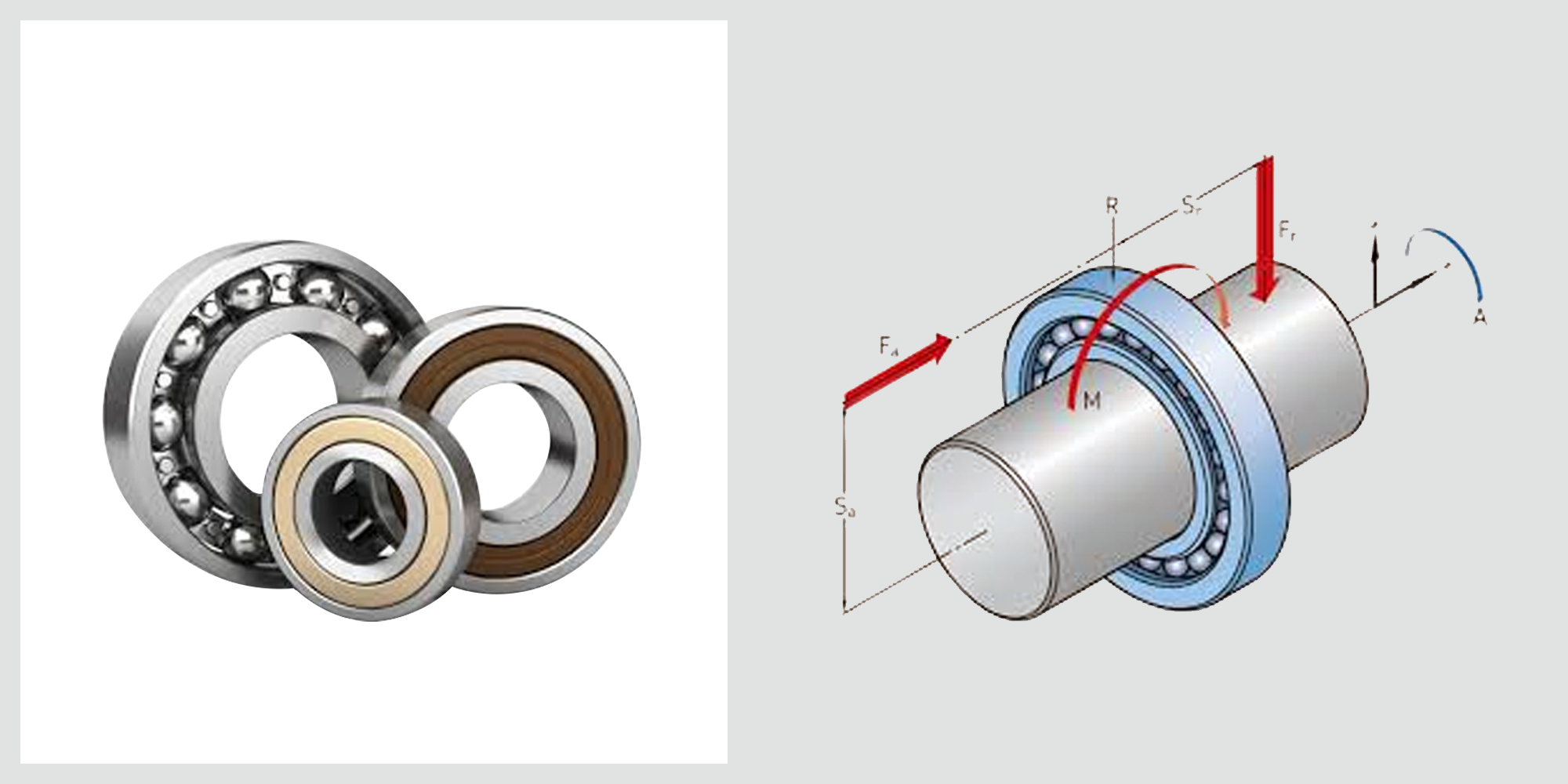

Bearing designs like angular contact ball bearings enhance stiffness.

They allow the balls to support both radial and axial loads.

This design feature enables them to handle higher speeds and loads without significant deflection.

Additionally, angular contact bearings reduce wear by distributing loads evenly across the rolling elements, which minimizes friction and heat generation.

This combination of stability and reduced wear helps ensure that high speed bearings operate efficiently. It also contributes to a longer lifespan.

High speed bearings are essential for managing both axial and radial loads while operating at extreme speeds.

Their specialized designs, such as angular contact configurations, allow them to handle forces from multiple directions effectively.

By distributing loads evenly across the rolling elements, these bearings minimize wear and extend lifespan.

Advanced lubrication systems further enhance performance by reducing friction and preventing overheating.

Overall, the combination of precise engineering, material selection, and effective load management ensures that high speed bearings perform reliably in demanding applications.

High speed bearings are crucial in various industries, such as turbochargers, spindles, and gas turbines. They enable components to operate at extreme speeds while effectively managing both axial and radial loads.

This ensures stability and precision in applications where performance is critical.

For example, it enhances engine power in automotive turbochargers and ensures machining accuracy in manufacturing spindles.

Overall, the reliability of high speed bearings directly impacts the efficiency and longevity of the systems they support.

High-speed ball bearings are often used because they can handle dynamic loads well and reduce internal friction.

This makes them ideal for applications where smooth and efficient movement is important.

In CNC machines, high-speed ball bearings help the cutting tools and spindle move smoothly and accurately.

This is important for precise machining and efficient production, as they reduce friction and improve performance.

In the medical field, these bearings are found in devices like surgical robots and MRI machines.

Their smooth operation and quiet performance are essential for safety and effectiveness in medical procedures.

In aerospace, high-speed ball bearings are used in engines, landing gear, and control systems.

They can handle tough conditions, like high speeds and heavy loads, ensuring the safety and performance of aircraft.

Air bearings are specialized bearings that use a thin film of pressurized air to create a non-contact surface for rotation.

This design allows the moving parts to float on a cushion of air, reducing direct contact between surfaces.

As a result, air bearings provide extremely precise motion. This makes them ideal for applications that require high accuracy and stability.

Because there is no metal-to-metal contact, air bearings significantly reduce friction and heat generation during operation.

This feature not only enhances the efficiency of the system but also extends the lifespan of the bearings.

Air bearings are particularly valuable in low-power, high-precision applications such as semiconductor manufacturing.

In this industry, precise motion is essential for processes like photoetching and wafer inspection. Even the slightest misalignment can lead to defects.

Air bearings provide a non-contact solution that allows for smooth and accurate movement of equipment. This design eliminates the friction and heat associated with traditional bearings.

Magnetic bearings use magnetic fields to support high-speed rotation without any physical contact between moving parts.

They achieve this by using electric magnets or permanent magnets to create a magnetic field.

This levitates the rotor, allowing it to spin freely. This non-contact design eliminates friction, resulting in minimal wear on the components.

In turbo compressors, magnetic bearings support the compressor shaft without touching it.

This helps the compressor run efficiently and last longer because there is less wear and tear.

Turbo blowers also use magnetic bearings to maintain high-speed performance with less noise and friction.

This improves their efficiency in moving air or gas quickly.

Magnetic bearings are found in other machines like industrial motors, centrifuges, and flywheels.

They are great for high-speed use because they reduce maintenance needs and operate smoothly.

Fluid film bearings use a layer of lubricant, usually oil, to create a thin film that separates moving components.

This lubricant forms a cushion between the bearing surfaces, allowing them to slide over each other without direct contact.

This design provides several advantages, including high load capacity and effective damping of vibrations.

Fluid film bearings are ideal for large industrial machines that operate at high speeds and handle heavy loads.

They use a layer of lubricant to evenly distribute weight, providing high load capacity.

The non-contact design reduces friction and wear, allowing for smooth operation.

Additionally, their damping properties help absorb vibrations, enhancing the performance and reliability of the machinery.

High speed bearings are essential for enabling machinery to operate with maximum efficiency and precision, even under extreme conditions.

They reduce friction between moving parts, leading to smoother operation and less energy loss.

Designed to withstand harsh environments, these bearings maintain performance in high temperatures and heavy loads.

Additionally, their vibration-damping features enhance stability, further improving both efficiency and accuracy in various applications.

The use of advanced materials like ceramics enhances the lifespan of high speed bearings.

This is achieved by reducing wear and generating less heat during operation.

Ceramics are lighter and harder than traditional materials, allowing them to withstand heavy loads without significant degradation.

Additionally, precision design ensures perfect alignment and optimal load distribution, minimizing stress and extending the operating life of the bearings.

High speed bearings are designed with optimized geometries that minimize the contact area between rolling elements and raceways. This design reduces friction and heat generation.

The use of advanced materials, like ceramics, and precision manufacturing ensures perfect alignment, further decreasing wear during operation.

Additionally, effective lubrication systems provide optimal distribution, maintaining a consistent lubricant film that enhances reliability and extends the lifespan of the bearings.

|

Benefit |

Description |

|

Improved Efficiency |

High-speed bearings reduce friction, enhancing the overall efficiency of machinery. |

|

Reduced Heat Generation |

Designed for high-speed applications, these bearings minimize excessive heat buildup, ensuring smoother operations. |

|

Increased Durability |

With advanced materials and design, high-speed bearings can withstand higher stresses, improving service life. |

|

Higher Load Capacity |

They are capable of handling higher loads at elevated speeds, making them suitable for demanding applications. |

|

Enhanced Precision |

High-speed bearings maintain precise motion control, ensuring accurate performance, which is critical in sectors like aerospace and medical equipment. |

|

Low Vibration and Noise |

Designed to operate at higher speeds with minimal vibrations, these bearings contribute to quieter machinery operation. |

|

Corrosion Resistance |

Many high-speed bearings are made of corrosion-resistant materials, allowing them to perform in harsh environments. |

|

Reduced Maintenance Needs |

Due to their durability and efficient design, high-speed bearings often require less frequent maintenance or replacements. |

When selecting a bearing for your application, first determine the maximum RPM.

Then, calculate the surface velocity to ensure it meets the required specifications.

Consider the load capacity to ensure the bearing can support the necessary axial and radial loads.

Additionally, choose materials that offer low friction and high wear resistance, such as ceramics or treated steels.

Lastly, evaluate the lubrication method and operating environment to ensure conformity and durability under the specific conditions of your application.

Different types of high speed bearings are designed to cater to various load capacities and environmental conditions.

For instance, ceramic bearings are well-suited for high-speed applications. They can handle high temperatures because their excellent heat resistance and low friction characteristics.

This makes them ideal for environments where heat is a concern.

On the other hand, stainless steel bearings are better for corrosive environments because they resist rust and chemical damage. This ensures reliable performance in harsh conditions.

Additionally, fluid film bearings are suitable for heavy load applications, providing high load capacity and effective damping.

Magnetic bearings excel in extreme conditions where maintenance needs to be minimized. Both types of bearings offer unique advantages for specific applications.

When deciding between steel and ceramic bearings, consider weight, friction, durability, and cost.

Ceramic bearings are lighter, making them great for applications where saving weight is important.

In contrast, steel bearings are usually cheaper for general use.

Ceramics also have lower friction, which helps machines run more efficiently and produces less heat.

They tend to last longer in tough conditions, whereas steel bearings are good for less demanding situations.

Weighing these factors will help you choose the best bearing type for your needs.

High speed bearings are essential in many industries because they help machines run at high speeds.

If you're looking for the best high-speed bearing for your needs, it's a good idea to consult with Lily Bearing.

We can provide expert advice and help you choose the right type of bearing based on your specific application.

Bearing clearances, whether in ball bearings like the 608 Bearing or roller bearings, play a crucial role in the intricate world of precision...

Slewing bearings, also known as slew bearing or slewing ring bearings, facilitate pivotal movement in machinery, handling axial, radial, and moment...

Bearings may be small components, but they have a big job. That includes everything from supporting loads in rotating shafts to absorbing axial...