Bearing Seal Types & How to Select the Best

Whether you’re working with roller bearings, stainless steel ball bearings, or spherical roller bearings, bearing seals play an essential role in...

Bearing retainers, also known as cages, play a vital role in the efficient functioning of a bearing.

They act as the backbone of the bearing system by maintaining the positioning of balls and rollers and ensuring load distribution.

This blog post will walk you through the bearing retainers, their types, benefits, issues, and how to make an informed choice when selecting one.

Bearing retainers are designed to ensure the proper alignment and spacing of balls or rollers within a bearing, thus preventing them from rubbing against each other and allowing them to operate smoothly.

They can also be used to facilitate lubrication by functioning as an oil reservoir, or by generating a solid film through the cage material or a coating applied to the cage.

Ball Bearing Retainers suit high-speed, low-friction applications and often focus on minimizing noise and vibration.

Roller bearing retainers, varying based on roller shapes like cylindrical, taper, and spherical, offer high load capacity and precision.

Roller bearing retainers, varying based on roller shapes like cylindrical, taper, and spherical, offer high load capacity and precision.

Bearing retainers can be made from a variety of materials, depending on the specific application and requirements of the bearing.

Metal retainers: These are usually made of steel or bronze and are known for their durability and strength. They perform well under high loads and temperatures but can be susceptible to corrosion.

Metal retainers: These are usually made of steel or bronze and are known for their durability and strength. They perform well under high loads and temperatures but can be susceptible to corrosion.

Plastic retainers: These are made of different types of plastics such as nylon, acetal, or PEEK. They are lightweight, corrosion-resistant, and suitable for high-speed applications but may not be ideal for high-temperature environments.

%20bearing%20retainer.jpeg?width=130&height=110&name=Nylon%20Crown%20(PA)%20bearing%20retainer.jpeg) Nylon Crown (PA) used in acetal plastic bearings; unsuitable for high-speed applications; corrosion-resistant; inner ring guided; temperatures ranging from -30°C to +100°C

Nylon Crown (PA) used in acetal plastic bearings; unsuitable for high-speed applications; corrosion-resistant; inner ring guided; temperatures ranging from -30°C to +100°C

.jpg?width=124&height=118&name=Reinforced%20Nylon%20Crown%20(TW).jpg) Reinforced Nylon Crown (TW) better sliding than a steel bearing retainer; fewer fluctuations in running torque high-speed low-noise; ball guided; temperature range: -30°C to +120°C

Reinforced Nylon Crown (TW) better sliding than a steel bearing retainer; fewer fluctuations in running torque high-speed low-noise; ball guided; temperature range: -30°C to +120°C

%20bearing%20retainer.png?width=125&height=133&name=Polyethylene%20Crown%20(PE)%20bearing%20retainer.png) Polyethylene Crown (PE): low speed; used in 316 stainless steel bearings; corrosion resistance; Temperature range: -40°C to +80°C Inner ring guided

Polyethylene Crown (PE): low speed; used in 316 stainless steel bearings; corrosion resistance; Temperature range: -40°C to +80°C Inner ring guided

%20bearing%20retainer.png?width=127&height=140&name=PEEK%20Crown%20(PK)%20bearing%20retainer.png) PEEK Crown (PK): highly corrosion resistant; for ceramic bearings, 316 stainless steel bearings, PEEK bearings, hybrid and/or super-precision ball and cylindrical roller bearings; Appropriate for use in a vacuum; Inner ring guided; temperature: -70°C to +250°C

PEEK Crown (PK): highly corrosion resistant; for ceramic bearings, 316 stainless steel bearings, PEEK bearings, hybrid and/or super-precision ball and cylindrical roller bearings; Appropriate for use in a vacuum; Inner ring guided; temperature: -70°C to +250°C

%20Bearing%20Retainer.png?width=136&height=138&name=PTFE%20Crown%20(PT)%20Bearing%20Retainer.png) PTFE Crown (PT): for ceramic bearings, 316 stainless steel bearings and PTFE bearings Temperature: -190°C to +200°C; highly corrosion resistant; Inner ring guide

PTFE Crown (PT): for ceramic bearings, 316 stainless steel bearings and PTFE bearings Temperature: -190°C to +200°C; highly corrosion resistant; Inner ring guide

Phenolic Resin Retainers: made from linen or paper based phenolic materials; capacity to soak up oil-based lubricants and to provide additional lubrication to the moving elements used in high-temperature applications; offering impressive strength and wear resistance.

Phenolic Resin Retainers: made from linen or paper based phenolic materials; capacity to soak up oil-based lubricants and to provide additional lubrication to the moving elements used in high-temperature applications; offering impressive strength and wear resistance.

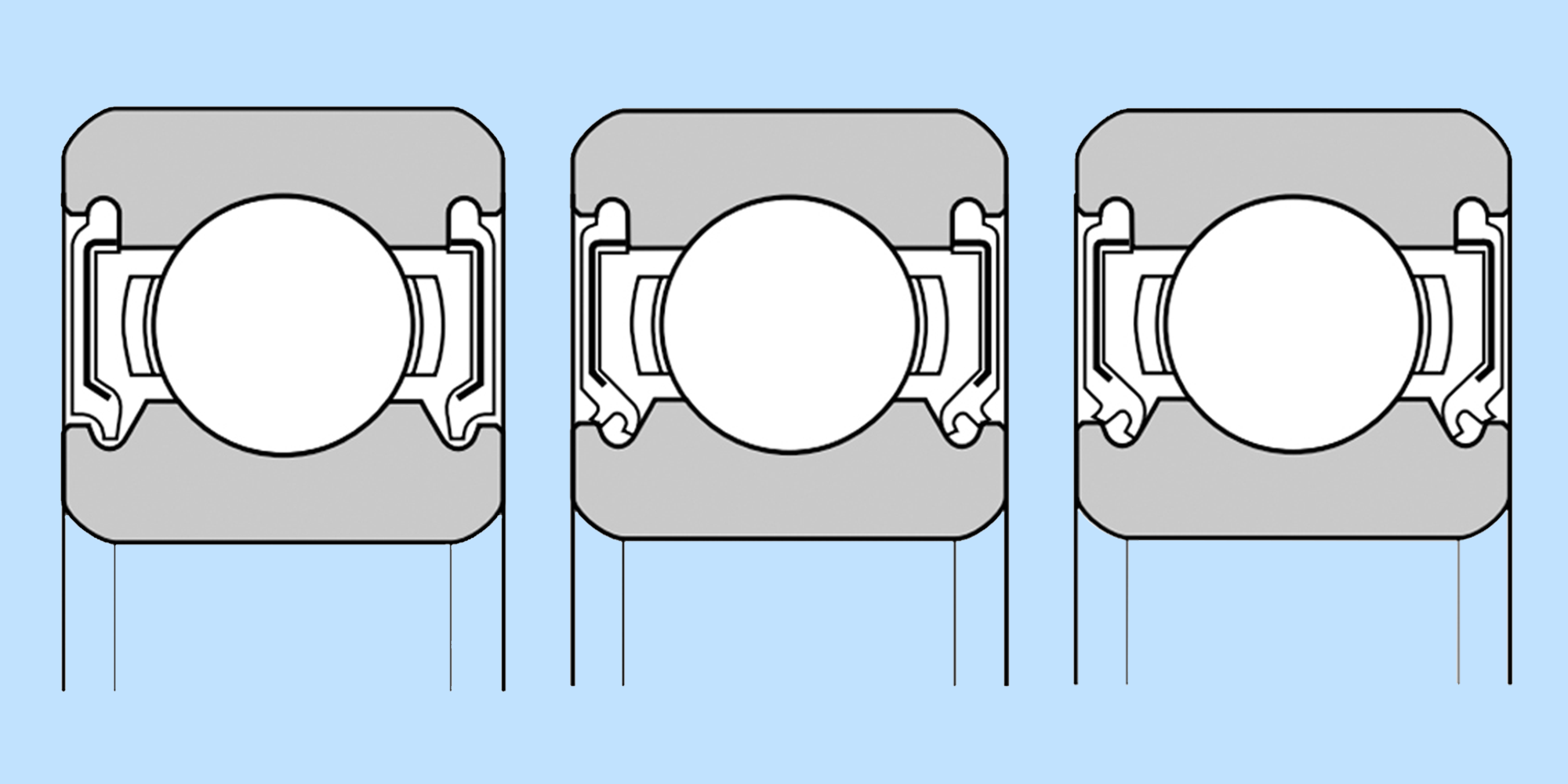

From the shape, common bearing retainers include:

When selecting a bearing retainer, several factors come into play, significantly impacting the bearing's overall performance and longevity.

These problems can degrade bearing retainers and bearing performance over time.

Remedying these concerns requires diligent inspection, replacement of damaged components, and adherence to regular maintenance procedures.

Ensuring proper installation, alignment, and bearing load management, coupled with routine checks for fatigue signs, can mitigate these issues and prevent premature bearing failure.

Bearing retainers and ball separators both serve to maintain even spacing between the rolling elements in a bearing, reducing friction and wear.

However, while retainers cater to a variety of bearing types, including both ball and roller bearings, ball separators are specifically designed for ball bearings.

The choice between the two hinges on the bearing type and specific application requirements, with retainers offering broader versatility and separators excelling in high-speed ball bearing applications.

Bearing retainers are crucial for reducing friction and increasing the lifespan and reliability of bearings.

Picking the right retainer is key to optimal performance.

LILY Bearing provides a range of high-quality retainers, understanding their vital role in bearing efficiency.

Remember, choosing the right retainer contributes to the overall success of your machinery.

For expert guidance, LILY Bearing is always ready to help.

Whether you’re working with roller bearings, stainless steel ball bearings, or spherical roller bearings, bearing seals play an essential role in...

Bearings are crucial components in mechanical equipment, with precision, performance, and reliability determining the mainframe's output. The...

Bearings play a critical role in the health of industrial machinery, ensuring operations run without a hitch. The processes of 'how to install a...