What Are Bearings and Their Functions?

Bearings are often unseen, yet they play a fundamental role in ensuring the smooth and efficient functioning of countless machines, devices, and...

In the vast world of machinery, ever pondered the question, "how do bearings work?" These unassuming devices play a monumental role in numerous machines. Tasked with reducing friction and enabling smooth operations, industrial bearings are indispensable to countless applications.

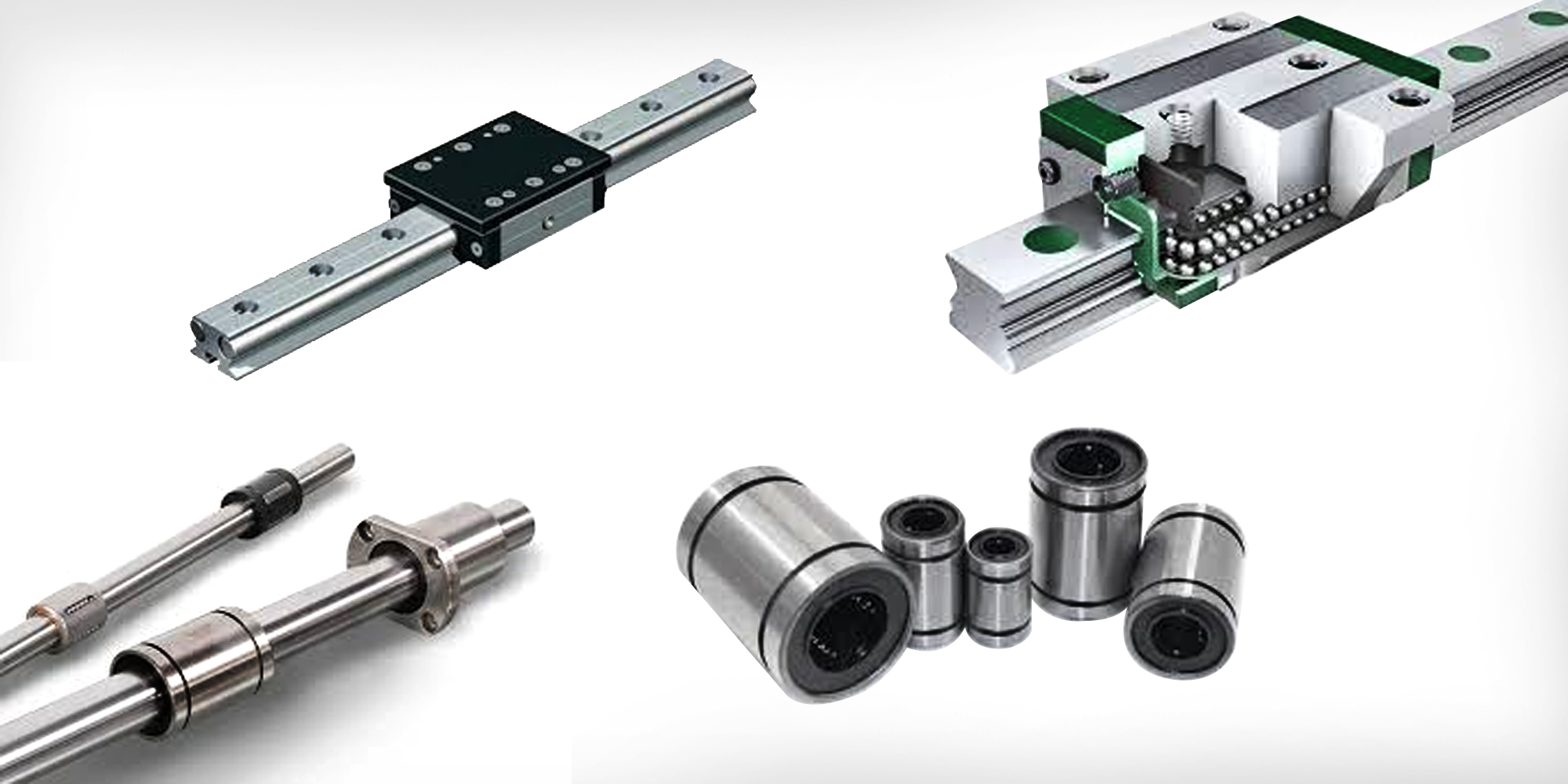

Fig 1 Types of Bearings

Bearings are mechanical components that reduce friction between moving parts, guiding them in either rotational or linear movement. They're pivotal for efficient machine operation. In rotation, as seen in car wheels or fans, they allow parts to spin around an axis. In linear movement, like machinery or drawer slides, they permit straight-line motion. By minimizing direct contact, they ensure smooth operation and prolong component lifespan.

Bearings consist of intricately designed elements that work in harmony to minimize friction and enable movement. Here are the primary components:

When a load is applied, it’s transferred from the inner ring, through the rolling elements, to the outer ring, facilitating smooth rotation or movement with minimal resistance.

Bearings function on the principles of load distribution and dynamics. Key aspects of their operation include:

Bearings distribute load across multiple rolling elements, preventing single-point contact, which would escalate wear and friction. This distribution ensures smooth rotation by reducing contact between moving parts.

In essence, bearings meld load distribution principles with strategic design and placement of rolling elements to reduce friction and wear effectively.

Bearing rings, including inner and outer rings, are commonly used for radial bearings.

Radial bearings handle loads perpendicular to the shaft's axis. The rings in radial bearings , like thin section bearings, deep groove ball bearings, are typically designed to accommodate these loads with the bearing's entire width.

Fig 2 Structure of a Sealed Radial Ball Bearing

Bearing races, including shaft races and housing races, are used for thrust bearings , including thrust ball bearings and thrust roller bearings.

Both races are engineered to work in harmony, enabling the rolling elements to move smoothly while handling axial loads efficiently.

fig 3 Structure of Thrust Bearings

Rolling elements, pivotal to bearings, determine their efficiency and functionality. Their primary goal is to diminish friction and guarantee consistent motion. Let's delve into these vital components.

These spherical elements offer point contact with bearing races. Suitable for both radial and thrust loads, they're ideal for lighter applications due to their minimal contact area.

Contrasting balls, rollers provide a line contact, making them adept for heavier radial loads. Varieties include:

The choice of rolling elements depends on specific application requirements, such as load type, operation speed, and environmental conditions. While ball bearings excel in high-speed, low-load scenarios, roller bearings, such as needle, cylindrical, tapered and spherical roller bearings, are tailored for high-load, low-speed operations.

The cage/ retainer is a pivotal component in a bearing's anatomy, ensuring the efficient operation of the bearing. Its primary role is to maintain consistent spacing between the rolling elements, preventing potential clashes that could lead to increased friction and reduced bearing life.

Cages come in varied designs, each tailored to specific bearing demands:

The choice between pressed and machined cages depends on specific load, speed, and performance requirements.

Fig 4 Pressed Cage Vs Machined Cage

The efficiency of bearings hinges on the synchronized interplay of its core components: bearing rings, rolling elements, and cages. The rings provide the pathway, the rolling elements bear the load and ensure smooth rotation, while the cages keep these elements equidistant. Together, their combined action ensures optimal friction reduction and facilitates fluid, seamless rotation in various machinery applications.

Lubricants are the unsung heroes when considering how bearings work efficiently. By reducing friction and protecting against wear and tear, bearing lubricants, whether grease or oil, play a vital role in bearing performance.

Lubricants, beyond reducing friction, play a pivotal role in heat dissipation within bearings. As bearings operate, they generate heat; lubricants assist in drawing this heat away, maintaining optimal operating temperatures. Efficient lubrication not only protects the bearing components from premature wear but also significantly extends the service life of the bearing, ensuring stability and consistent performance over extended periods.

Bearings represent a harmonious interplay of elements, each crucial for stable and efficient rotation. The synergy of bearing rings, rolling elements, and cages ensures precise and uninterrupted movement. Complementing this, lubricants further refine the process, ensuring smoothness and reducing wear. Together, these components and substances epitomize the essence of optimal bearing operation.

Conclusion: Paving the Way for Constant Rotation

So, how do bearings work? Through the synchronized efforts of bearing rings, rolling elements, cages, and lubricants, they ensure continuous, stable, and smooth rotations in machines. Their legacy in engineering is a testament to their unparalleled importance.

Bearings are often unseen, yet they play a fundamental role in ensuring the smooth and efficient functioning of countless machines, devices, and...

In the realm of modern machinery, linear bearings stand out as pivotal elements. Their role is monumental, but it's the meticulous design behind them...

Industrial bearings are essential in industrial machinery, enabling smooth operation and reducing wear for prolonged equipment life. There exists a...