Understanding the Importance of Bearing Clearance

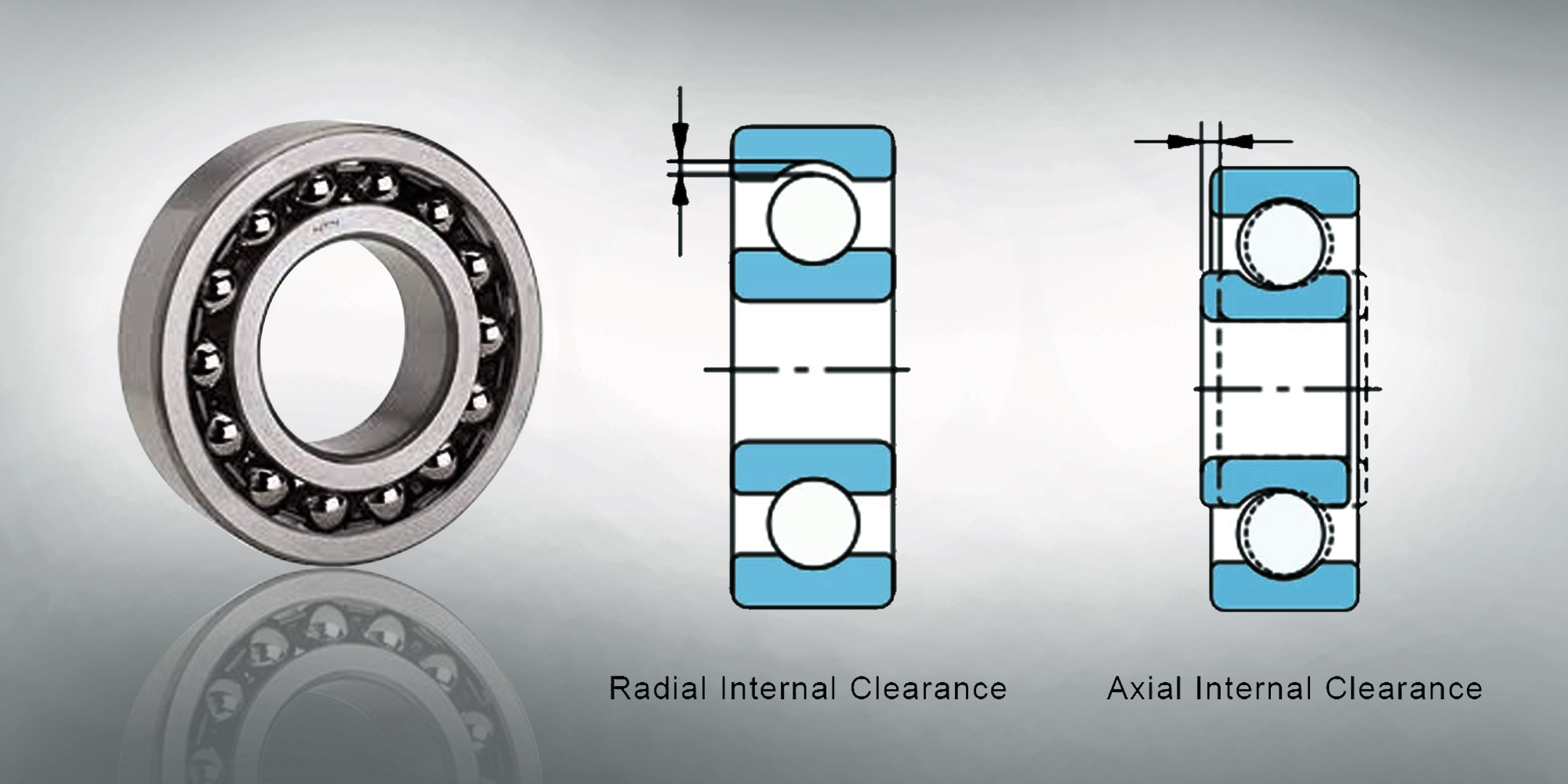

Bearing clearances, whether in ball bearings like the 608 Bearing or roller bearings, play a crucial role in the intricate world of precision...

Bearing wear is a significant concern in machinery.

It not only hampers the efficiency of the machine but can also lead to premature bearing failure if not properly addressed.

In this guide, we delve into the types and causes of bearing wear.

We also provide insights into choosing the right grease to prevent premature bearing wear and failure.

Let's navigate through this intricate world of wear and solutions.

Bearings encounter different wear patterns during their use.

Knowing these signs will help in better maintenance and ensures machinery runs smoothly.

Adhesive wear, commonly termed 'smearing', results from two interacting surfaces sliding, causing material transfer.

This wear typically increases with load and sliding distance but reduces with surface hardness.

This wear stems from the angular acceleration of rolling elements, leading to material transfer between ring raceways and rolling elements, often seen as scuffing or scoring marks.

Fretting wear, or 'Tribo-corrosion', occurs on bearing raceways due to insufficient lubrication, leading to metallic contact and evident oxidization, often seen as red or black iron oxide.

False brinelling occurs during stationary bearing operation due to minor axial movements of the rolling elements, causing wear-like indentations on the raceway without the protective barrier of an oil film.

Wear marks, typically brown from corrosion, show distinct hardening, especially in ball bearings, with clear boundaries separating them from adjacent surfaces.

While there are situations where false brinelling is unavoidable, such as during ocean freight shipping of machinery, measures can mitigate its occurrence:

Distinguishing it from true brinelling involves examining the wear: false brinelling erases the surface texture, while true retains it.

To combat bearing wear and ensure the optimal performance and longevity of rolling bearings, the right lubrication choice is crucial.

Grease performance is heavily influenced by its base oil type.

This component determines the lubricant film's formation.

Commonly used base oils include mineral and synthetic oils.

It's essential to recognize that synthetic oils vary—like polyalphaolefin, polyglycol, and ester—each having distinct characteristics.

Thickeners play a pivotal role in grease consistency.

Metal soaps, metal complex soaps, and emerging organic or polymer thickeners like polycarbamide are typical thickening agents.

All greases contain additives, categorized by their effects.

Some additives influence the oil itself, such as oxidation inhibitors and detergents, while others, like anti-wear additives and corrosion inhibitors, affect the bearing or metal surface.

Greases are classified by their principal components: thickener and base oil.

Their consistency is determined by NLGI grades, based on the 'worked penetration' per ISO 2137. A higher NLGI grade denotes harder grease.

For rolling bearings, greases of NLGI grades 1, 2, or 3 are preferred.

To reduce bearing wear, selecting the appropriate grease is crucial.

Various operational and environmental factors influence this choice, directly impacting bearing longevity and efficiency.

Match the speed parameter of the bearing to the grease. High-speed bearings require greases with high-speed parameters and vice versa.

For significant loads, greases with higher base oil viscosity and anti-wear additives are essential to prevent wear, especially under combined radial and axial loads.

It's crucial to choose greases with proven mechanical stability to prevent changes in consistency.

In this blog, we delved into the complexities of bearing wear, examining bearing wear patterns and referencing a bearing wear chart for in-depth understanding.

It is imperative to comprehend bearing wear to make informed decisions regarding lubrication.

Selecting the appropriate grease is vital for reducing wear and ensuring machinery reliability.

Lily-bearing is committed to providing reliable bearings to meet these needs.

Bearing clearances, whether in ball bearings like the 608 Bearing or roller bearings, play a crucial role in the intricate world of precision...

Full complement bearings are often overlooked in the assembly of bearings. Unlike rubber seal, steel seal, open type, and UG bearings that we are...

The 6202RS bearing is a versatile, single-row deep groove ball bearing with rubber seals on both sides. Commonly used in electric motors, automotive...