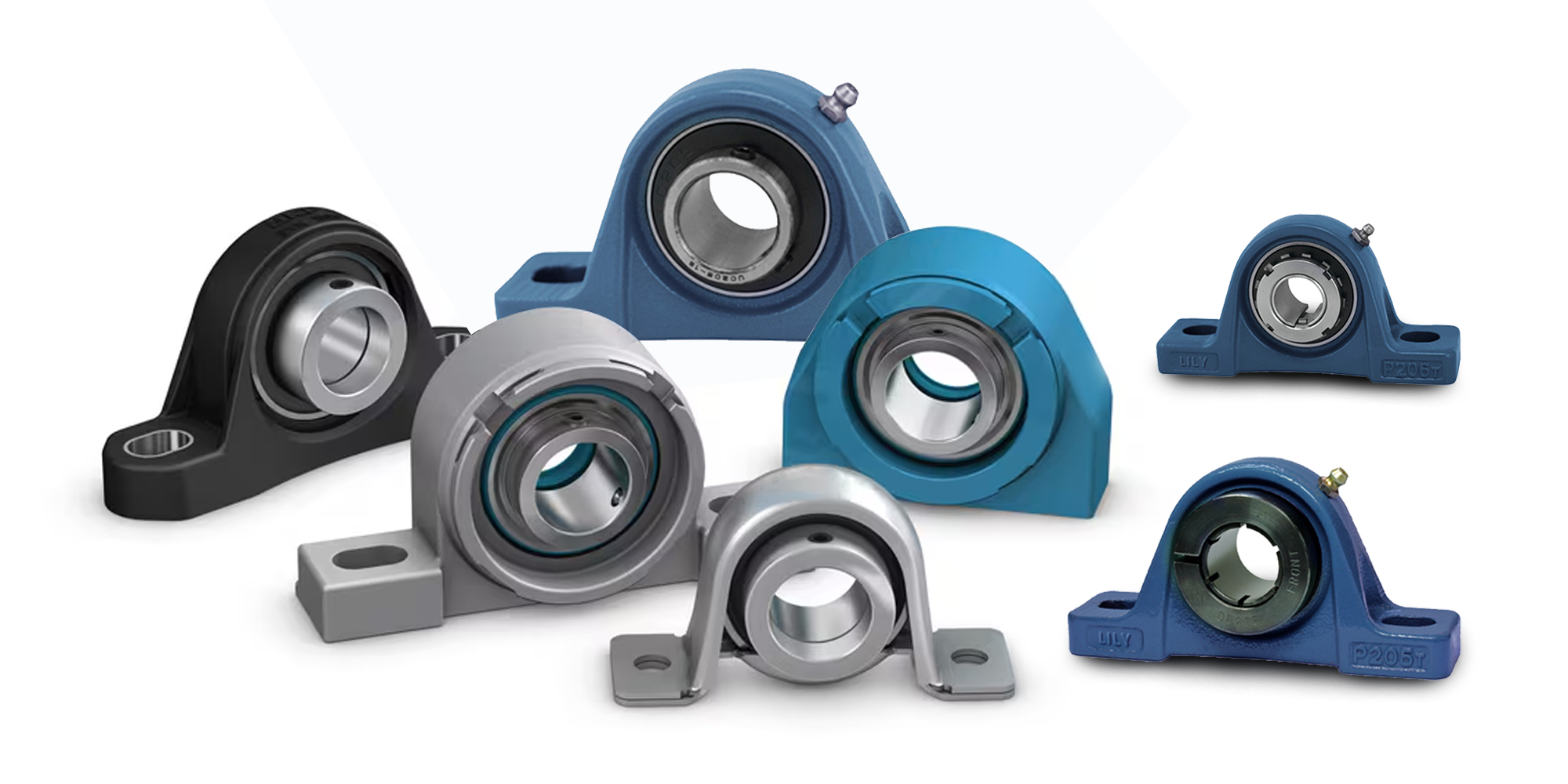

Mounted Bearings: Types, Advantages, and Uses

In the world of machinery, mounted bearings play a pivotal role. They are integral to the smooth operation of various equipment across industries. ...

Table of Contents

Pillow block bearings are vital elements across diverse machinery.

These mounted bearing units support rotating shafts and keep them stable for seamless operation.

This blog post explores what pillow block bearings are, their components, types, materials, applications, sealing, lubrication, and how to select the best one.

A Pillow block bearing is a pre-assembled housing with a machined mounting surface.

It is commonly used in mechanical power transmission systems to support shafts and couplings.

The shaft runs parallel to the mounting surface, while the mounting screws are typically positioned perpendicular to it.

It has a bearing insert inside a pillow-shaped casing or block. This insert can accommodate various bearing types, including:

Rolling element bearings, such as:

or plain bearings (like sleeve bearings or bushings), depending on the application's specific load and speed requirements.

The block is designed to be securely bolted to a foundation or machine frame.

Fig 1 Components of a Pillow Block Bearing

The spherical outer ring of the bearing insert perfectly mates with a corresponding spherical bore in the housing.

In this design, pillow block bearings can compensate for minor misalignments between the shaft and the mounting surface.

These units typically accommodate static misalignments of ±2° to ±5°. This ensures stable performance even if mounting surfaces are slightly uneven.

Fig 2 Self-alignment of Pillow Block Bearings

While often confused, pillow and plummer blocks differ significantly in supply and typical use.

|

Feature |

Pillow Block Bearings |

Plummer Block Bearings |

|

Assembly |

Pre-assembled unit with bearing included |

Housing only; bearing installed separately |

|

Load Capacity |

Generally for light to medium-heavy loads |

Often for higher, more robust applications |

|

Environment |

Versatile |

Frequently for corrosive/harsh environments |

Both securely mount a bearing to allow inner ring rotation while bolting to a foundation.

Pillow block bearings come in various forms, each suited for specific application requirements. Here's a breakdown by common categories:

The housing's design often dictates the unit's primary application and mounting orientation.

These are the most representative and common type. The housing is made for the whole assembly to be mounted vertically on the equipment. It uses its mounting holes to securely support shafts.

Fig 3 Standard Pillow Block Bearing

Fig 3 Standard Pillow Block Bearing

Models: Often starting with UCP, UKP, NKP+H, or NAP;

They are widely used in scenarios requiring vertical shaft support, such as:

With a narrower width than standard designs and built-in mounting holes at the base, they are well-suited for applications with limited space.

Fig 4 Tapped Base Pillow Block Bearing

These designs have a higher center than standard units. This makes them suitable for uses where the shaft is much above the mounting surface.

Fig 6 High Center Pillow Block Bearing

Pillow block bearings use different ways to attach the bearing insert to the rotating shaft. They often use a locking collar or connect directly to the shaft.

They are secured to the shaft using set screws that tighten against the shaft.

An eccentric collar is tightened onto the shaft, which in turn secures the bearing.

A concentric collar is clamped onto the shaft, offering a more balanced hold.

An adapter sleeve is used to mount the bearing onto a stepped or plain shaft, allowing for easier mounting and dismounting.

Unlike single-piece solid housings, split pillow blocks are divided into two halves (a cap and a base).

.jpg?width=440&height=440&name=Split%20Pillow%20Block%20Bearings%20(2).jpg)

The performance and durability of pillow block bearings rely heavily on the materials used. This includes both the insert and the housing.

Pillow block bearings are incredibly versatile and found in a vast array of equipment and industries.

They are specially used in agriculture and food processing sectors.

Pillow block bearings are the workhorses of the agricultural sector.

They help equipment perform reliably in harsh conditions with dirt, dust, moisture, and heavy loads.

They are essential for supporting rotating shafts in almost every piece of farm machinery. This helps ensure reliable performance in the field.

Specific Equipment such as:

In the food processing industry, pillow block bearings are important for keeping equipment clean and running smoothly.

They can handle frequent washdowns and a wide range of temperatures.

Their design often uses food-grade, corrosion-resistant materials like stainless steel or thermoplastics.

They also include special seals to meet strict sanitation standards and follow regulations from agencies like the FDA.

Specific Equipment such as:

Since over 50% of bearing failures stem from contamination, selecting the right seal can extend service life by 1.5x to 3x.

Here are some common seal types.

The choice of seal type (e.g., lip seals & labyrinth seals) significantly impacts the bearing's ability to withstand contaminants and retain lubrication.

The need for lubrication in pillow block bearings depends largely on their design type and operating conditions.

Maintenance-Free Units are factory-sealed and pre-lubricated. They use effective seals to prevent grease leakage and block the ingress of impurities, dust, and water.

They are well-suited for most indoor and standard operating conditions.

While maintenance-free bearings suffice for standard indoor use, re-greasable types are essential for specific, more demanding applications:

For re-lubricatable types, a typical interval is 1,500–2,500 hours for clean environments, but this drops to 200 hours in dusty agricultural settings.

Selecting the right pillow block bearing involves evaluating several critical factors to ensure optimal performance and longevity.

The shape of the housing dictates its mounting orientation and suitability for specific space constraints or shaft positions.

Precise dimensions are crucial for a proper fit and optimal performance.

"Duty" means how well a bearing can handle steady loads and working conditions over time.

It's judged based on how the equipment will be used and the loads it’s expected to carry.

Load is a critical consideration as it directly influences the bearing's material, size, type, and expected service life.

Bearing Selection Based on Basic Dynamic Load Rating

The formula for bearing life is:

L10=(Cr/Pr)3

Where:

L10: Basic Rating Life (in millions of revolutions)

Cr: Basic Dynamic Radial Load Rating

Pr: Equivalent Dynamic Radial Load

You must select a bearing with a dynamic load rating greater than the expected operating load.

A safety factor of 1.2 is standard for smooth loads, while heavy-impact machinery often requires a factor of 2.0 to 3.0 to ensure sufficient capacity.

The operating environment plays a huge role in material and design choices.

High-Temperature Environments:

Often require stainless steel or ceramic bearings, along with specialized lubricants that maintain viscosity at elevated temperatures.

Standard units operate safely from -20°C to +120°C, while specialized high-temp models can withstand up to 250°C (482°F).

Low-Temperature Environments:

Demand materials that retain their integrity and do not become brittle in cold conditions.

Well-known manufacturers and brands of pillow block bearings include SKF, Timken, and Rexnord.

Other brands are Dodge, Sealmaster, Link-Belt, NSK, NTN, and FAG.

A failing pillow block bearing is typically indicated by abnormal noise, excessive vibration, overheating, lubricant leakage, or visible damage.

LILY bearings follow ISO 9001 standards, maintaining hole-to-hole tolerances within ±0.2mm for precision fitting.

Understanding their types, materials, and maintenance, alongside informed selection and diligent care, is crucial for significantly extending equipment life and minimizing costly downtime.

For expert guidance on optimizing your machinery's performance with the right pillow block bearings, contact LILY Bearing today.

In the world of machinery, mounted bearings play a pivotal role. They are integral to the smooth operation of various equipment across industries. ...

Mounted bearing—often referred to as pillow blocks or flange units—are the unsung heroes of the industrial world. They support rotating shafts,...

Set up an operating room in minutes? Even never need drape, dock, or move heavy equipment? Sure! One of Lily Bearing’s clients can make it come true.