Needle Bearings: Types and Features

Needle roller bearings are great for saving space while supporting heavy loads. Their small, cylindrical rollers reduce friction, making them perfect...

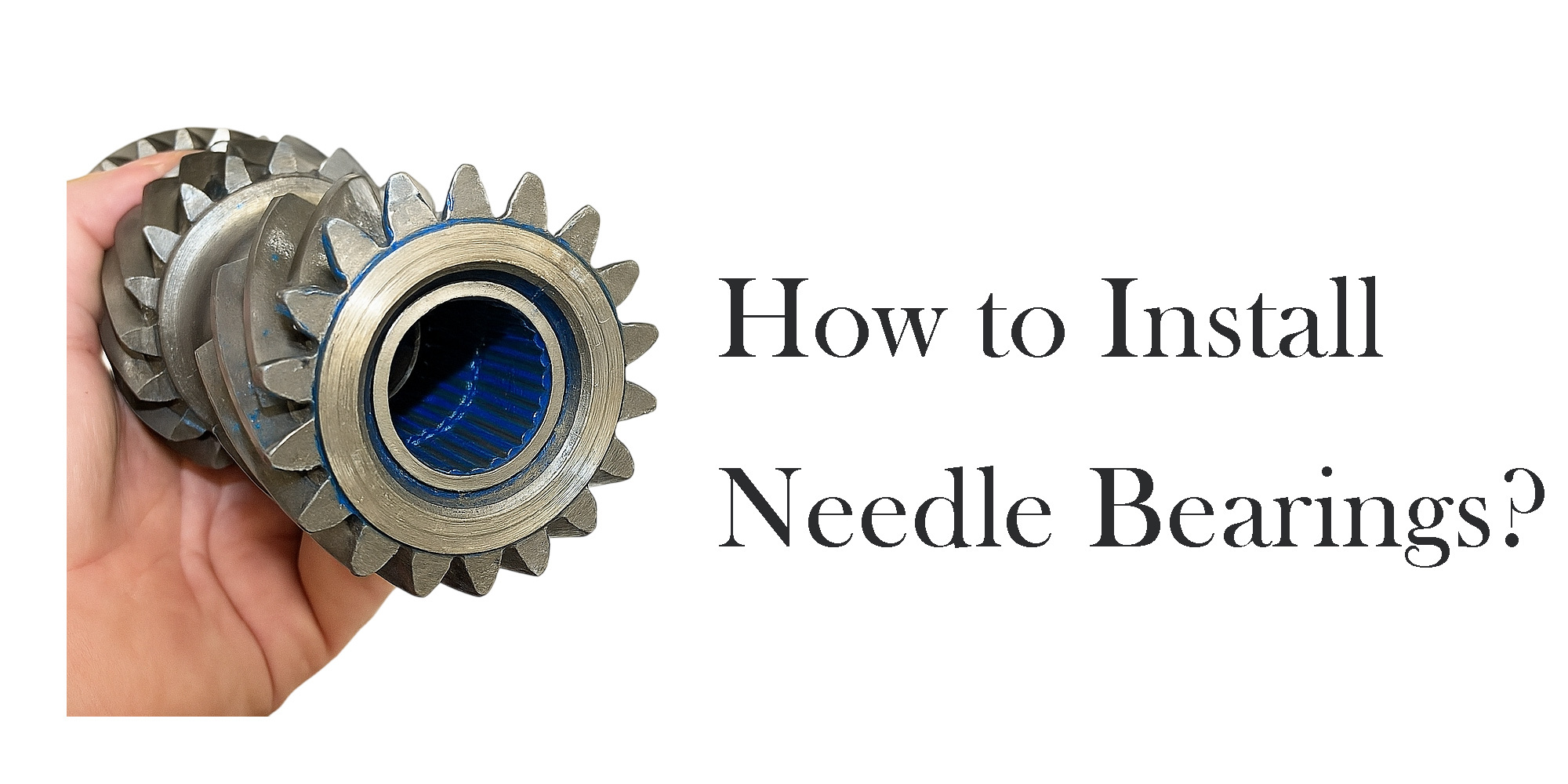

Needle bearings are a unique type of rolling-element bearing. They use long, thin cylindrical rollers, offering a high length-to-diameter ratio.

Known for their compact size and ability to handle greater loads, they are essential in many systems.

These components play a critical role in engineering and industrial applications.

This blog explores the practical applications of needle bearings across various industries. It highlights their key features and benefits.

Cylindrical needle rollers are the defining components of needle bearings.

They are designed to be significantly longer than their diameter.

Typically, their length-to-diameter ratio exceeds 3:1.

This unique geometry enhances their load carrying capacity without significantly increasing the bearing's overall size.

Needle bearings have excellent radial load capacity because of their long, thin rollers.

These bearings rollers provide a large contact area, distributing heavy loads evenly and reducing stress on the bearing.

This makes needle roller bearings ideal for handling heavy loads in tight spaces.

They are commonly used in industrial machines, car transmissions, and aerospace parts.

Their strong design also ensures durability and reliable performance under demanding conditions.

Needle bearings are compact and work well in tight spaces. Their small size makes them ideal for gearboxes, aerospace parts, and compact machines.

Even in confined spaces, they provide efficient, reliable performance and handle heavy loads effectively.

Needle bearings are used in the motor and gearbox of portable drills to support the rotating shaft and reduce friction, allowing for smooth and efficient operation.

They help ensure that the drill can maintain consistent power delivery during use.

In power saws, needle bearings are used in the motor and blade assembly, where they support the high-speed rotation of the blade and help minimize wear and vibration.

This ensures smooth cutting action and prolongs the life of the saw.

Needle bearings are used in various power tools such as grinders, sanders, and impact wrenches.

They are used in the rotating parts, including shafts and spindles, to handle the radial loads and reduce friction, ensuring efficient power transfer and smooth operation.

In domestic appliances like washing machines, vacuum cleaners, and blenders, needle bearings are used in motors, fans, and rotating components.

They provide support for moving parts and help reduce friction, contributing to the appliance's efficiency and durability.

These bearings are used in diverse, demanding fields:

Needle roller bearings are perfect for applications with tight space constraints. Their design maximizes performance in small, confined systems.

Needle bearings can handle much higher radial loads than other bearings of the same size.

Their long, thin rollers provide a large contact area, which helps spread the load evenly.

Heat-treated needle bearings are stronger and more durable because of the high-temperature process. This makes them wear-resistant and able to last longer.

With fewer replacements and less maintenance needed, they help reduce overall costs and downtime.

Needle bearings offer a range of flexible options to suit different needs.

They can be tailored with specific seals to protect against dirt and moisture. This ensures long-lasting performance in harsh environments.

Materials can be selected based on the application’s requirements.

For example, stainless steel offers corrosion resistance, while ceramic provides high temperature tolerance.

Needle bearings are available in various sizes to fit specific spaces. This makes them adaptable to a wide variety of machines and equipment.

These adjustments allow needle bearings to meet the demands of different industries and applications.

Needle bearings don't tolerate misalignment well because they rely on precise alignment to work properly.

If the shaft and housing are not aligned, it can cause uneven wear and reduce performance.

Misalignment can lead to higher friction, heat, and faster bearing failure.

Therefore, keeping everything properly aligned is crucial for their longevity.

Needle bearings can wear out quickly under high contact stresses. The long, thin rollers are more prone to damage when exposed to heavy loads, leading to increased friction and bearing wear.

If the stress is too high, it can shorten the bearing’s life and reduce performance.

Regular maintenance and proper lubrication help reduce this wear.

Needle bearings aren’t ideal for extremely high-speed applications because of their long rollers.

These rollers create more friction, which generates heat and can lead to overheating.

At high speeds, the rollers might not stay in contact with the raceways, reducing performance and causing wear.

For high-speed needs, other types of bearings, like ball bearings, are usually a better choice.

When selecting needle roller bearings, consider load requirements, space constraints, and environmental conditions.

Proper selection ensures reliable and efficient performance.

Drawn cup needle roller bearings are lightweight and compact, ideal for limited spaces.

Heavy-duty needle bearings handle intense loads, perfect for demanding applications.

Proper lubrication, alignment, and clean storage are vital for maintaining needle bearing performance.

These practices reduce friction and extend service life.

Needle roller bearings are versatile components used in numerous industries, from automotive and aerospace to industrial machinery and power tools.

By understanding their advantages and limitations, you can select the right needle bearing for your specific functional needs.

If you want to learn more about bearings, you can contact LILY Bearing. We offer a variety of high-quality bearing solutions, ranging from standard to customized types, capable of meeting the needs of various industrial applications.

Needle roller bearings are great for saving space while supporting heavy loads. Their small, cylindrical rollers reduce friction, making them perfect...

Needle bearings play a crucial role in applications where space, load capacity, and reduced friction are essential. Proper installation is critical...

Bearings are essential mechanical components used to reduce friction between moving parts. Among the various types of bearings, needle bearings and...