Understanding the Importance of Bearing Clearance

Bearing clearances, whether in ball bearings like the 608 Bearing or roller bearings, play a crucial role in the intricate world of precision...

Table of Contents

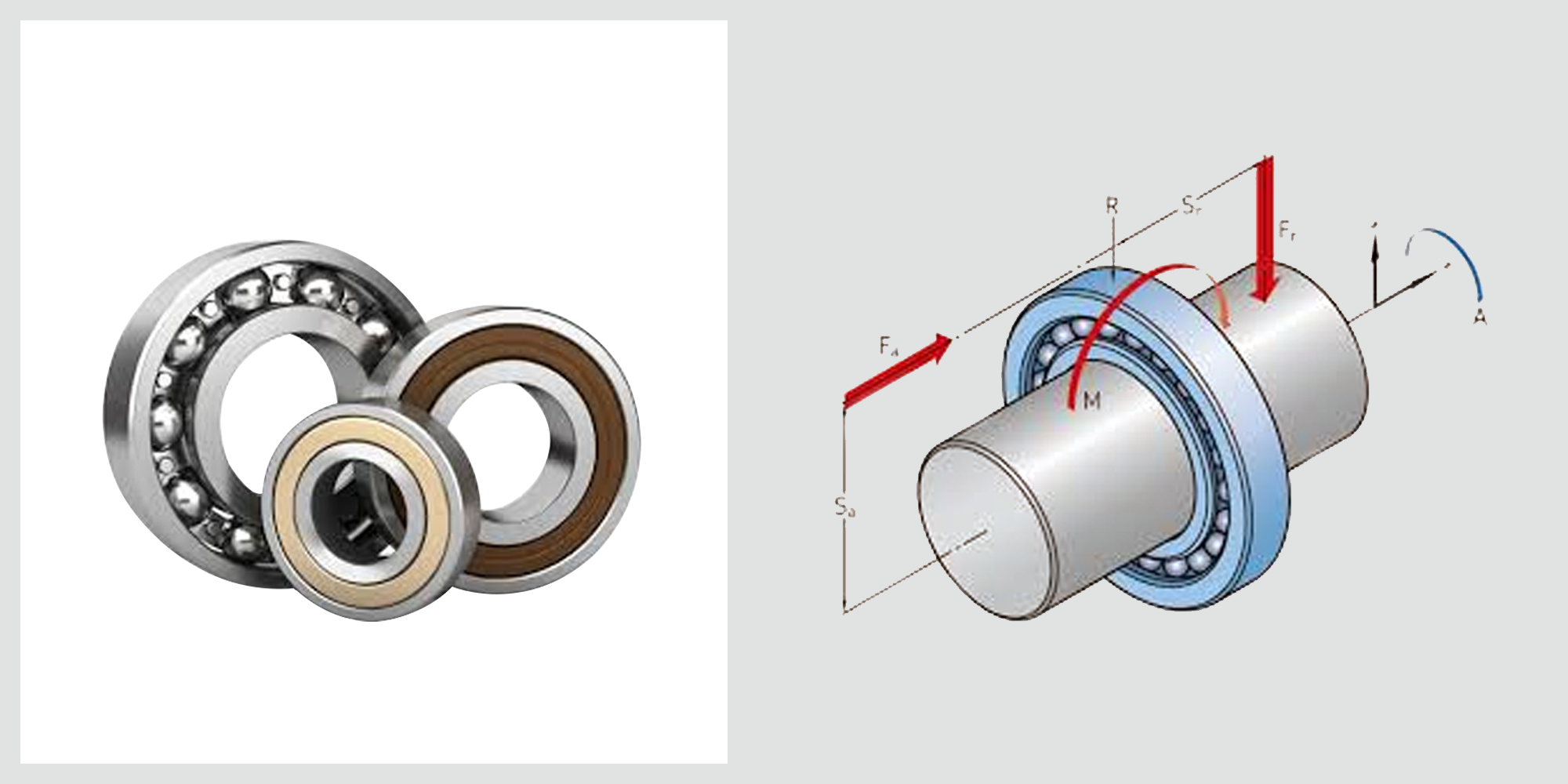

Bearings may be small components, but they have a big job.

That includes everything from supporting loads in rotating shafts to absorbing axial thrust in turbines.

At the heart of bearing performance is load, which is how much force the bearing can handle and how that force is applied under various operating conditions.

This guide breaks down the different types of bearing loads, how they affect performance, and what to consider when choosing a bearing for your application.

A bearing load is the amount of force or pressure exerted on a bearing.

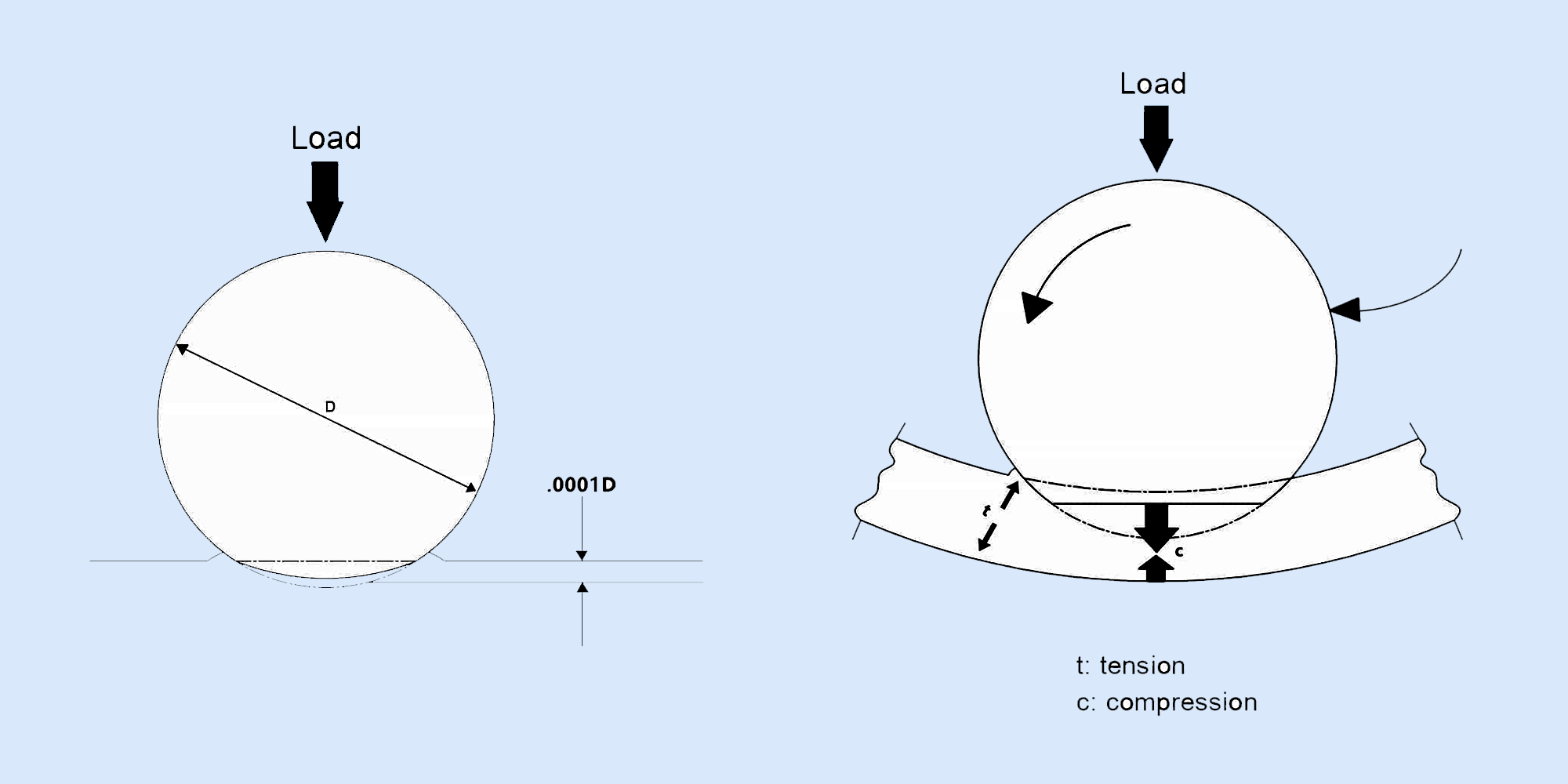

In detail, the force is transmitted from one bearing ring through some or all rolling elements to the other bearing ring.

Typically, application loads are transferred from the shaft to the bearing's inner ring, and then to the outer ring.

A bearing can withstand various loads, such as radial loads, axial loads, centrifugal loads, and more.

The magnitude and direction of bearing loads depend on various load factors and load conditions, including equipment weight, operating speed, acceleration, deceleration, shock, vibration, temperature, and lubrication.

Misalignment alignment, installation, or maintenance can also affect bearing loads.

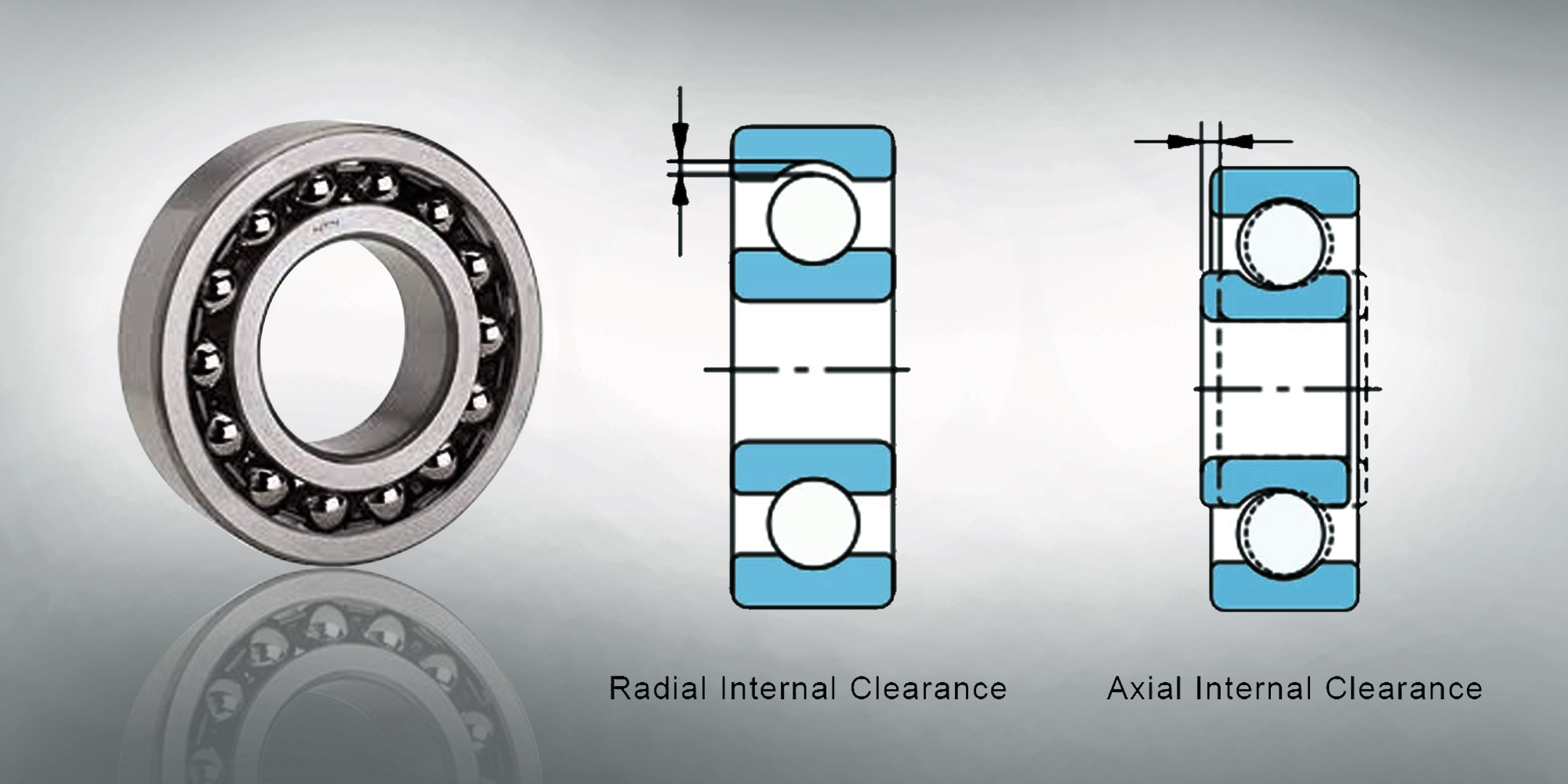

Radial bearing loads are perpendicular to the shaft's bearing axis and act on the outer ring. They are caused by the weight of the equipment or the force of rotating components.

To calculate radial load capacity, determine the weight of the components being supported and the forces acting on them, divide the load among the bearings, and ensure that the calculated load is within the maximum load capacity of the selected bearing using manufacturer specifications.

Typical radial loads consist of the weight of a horizontal shaft assembly, gears, pulleys, and cutting tools, etc.

If your application requires a radial load on the bearing, a radial ball bearing, cylindrical roller bearing, or an angular contact bearing with a low contact angle would be an excellent choice.

Deep groove ball bearings can also do the job, but they’re best reserved for lighter loads.

bearing radial load

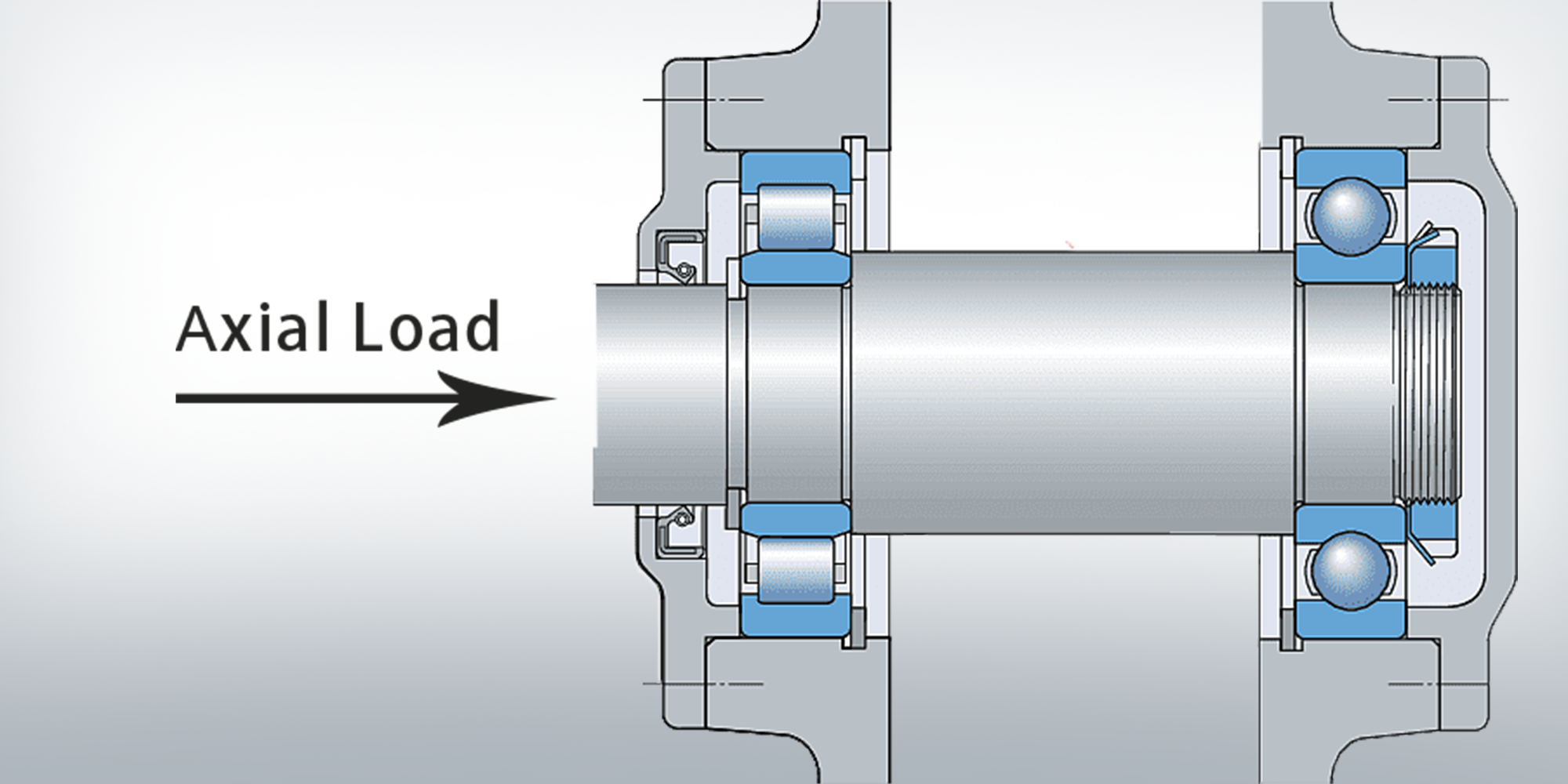

Axial loads, also known as thrust loads, are parallel to the shaft's axis and act on the bearing's inner or outer ring.

They are caused by thrust or tension forces and can be unidirectional or bidirectional.

They transfer force uniformly to create balanced load distribution.

An angular contact bearing with a higher contact angle typically around 25° is a good choice for applications with axial loads.

However, for offset axial loads, a moment force is applied to the inner race, resulting in non-uniform load distribution on the bearing's rolling elements.

To calculate axial load capacity, consider the bearing size, material, and geometry, as well as the load direction and magnitude.

Manufacturers rate bearings based on standardized formulas and testing.

Applications with high axial loads include pumps, automotive transmissions, and compressors.

bearing axial load

In many applications, bearings are subjected to radial and axial forces at the same time. This is called a combined load.

Bearings that can handle this type of load are required in systems where the direction and magnitude of the loads change dynamically, like gearboxes, automotive wheel hubs, and electric motors.

Bearing types like angular contact ball bearings or tapered roller bearings handle these loads effectively, but there are others as well.

These designs can accommodate multi-directional loads by managing both radial and axial loads at the same time.

Choosing a bearing that can withstand combined loads will give better performance, longer service life, and more reliability.

Choosing the right bearing with enough load capacity is crucial for efficient operation and the durability of machinery.

Too little capacity can cause early failure, downtime, repairs, and safety risks, while excessive loads can lead to overheating, wear, and increased energy usage.

Incorrect capacity can cause catastrophic failure, safety hazards, and costly downtime.

Consult with experts or bearing manufacturers to ensure proper capacity for your application.

Bearing load capacity can be calculated using various formulas and software programs, including those provided by the bearing manufacturers' catalogues, online calculators, and finite element analysis (FEA) simulations.

The most commonly used formulas for radial and axial loads are:

In this equation,

"C" is the basic dynamic radial load rating,

"P" is the dynamic equivalent load,

"C0" is the basic static load rating,

"Fr" is the radial load,

"Fa" is the axial load.

For accurate results when calculating bearing load capacity, seek expert advice or use software programs offered by bearing manufacturers.

The dynamic radial load rating (C) is key to estimating the life of a bearing.

The L10 rating life formula is used to calculate the number of revolutions at which 90% of identical bearings will still be running under a given load.

Bearing Life Formula:

L10 = (C / P)^3 × 10^6 revolutions

Where:

This formula shows that even a small increase in load (P) can shorten a bearing’s life, while reducing the load extends life.

this in when selecting a bearing leads to optimal performance and longer lifespan.

Selecting bearings with sufficient centrifugal load capacity is critical for high-speed applications to prevent premature failure.

Centrifugal loads can cause bearing deflection, vibration, and fatigue.

To calculate centrifugal load capacity, use formulas and software programs such as those found in manufacturers' catalogues, online calculators, and FEA simulations.

The most common formula is:

Centrifugal Load Capacity = (C0/P) x V^2 x 10^-9

Where:

"C0" is the basic static load rating,

"P" is the equivalent dynamic bearing load,

"V" is the bearing speed in rpm.

Centrifugal bearing loads result from the rotational speed of an application, particularly high-speed ones like turbines and centrifuges.

As the inner ring rotates, the rolling elements want to move tangentially in a straight path, but the outer ring must force them to follow the circular arc of the bearing.

This interaction produces a centrifugal radial load.

The maximum speed of an application can sometimes be limited by the powerful centrifugal load it generates.

Consider application requirements, load type, speed, environment, and temperature when selecting a bearing.

Ball bearings work for low to moderate loads, roller bearings are designed to handle higher loads and plain bearings are suitable for low-speed, high-load machinery.

Maintain bearings with regular inspection, cleaning, and lubrication to ensure optimal performance and longevity.

Before making the final selection of bearings for your machinery, you’ll need to fully grasp how varying load types act on bearings and which are best for managing them.

The table below gives a quick comparison of key load types and the best bearing choices for each.

|

Load Type |

Direction Relative to Shaft |

Typical Causes |

Suitable Bearings |

|

Radial |

Perpendicular |

Weight, belts, gear forces |

Deep groove ball, cylindrical roller |

|

Axial (Thrust) |

Parallel |

Thrust, end forces, tension |

Angular contact, thrust bearings |

|

Centrifugal |

Radial (from rotation) |

High-speed rotation |

High-speed bearings, hybrid bearings |

At LILY Bearing, we understand that every project comes with its own unique set of requirements.

That’s why we offer not just a wide selection of high-quality bearings, but also the technical expertise to help you make the best possible choice.

We work closely with engineers, designers, and procurement professionals across industries, from automation and automotive to aerospace and medical devices, to provide both off-the-shelf and customized bearing solutions tailored to your specific needs.

Our team of bearing specialists is ready to assist with application advice, custom solutions, or detailed technical support to ensure your project runs smoothly and efficiently.

Contact us today to find the best bearing for your specific application.

Bearing clearances, whether in ball bearings like the 608 Bearing or roller bearings, play a crucial role in the intricate world of precision...

Bearings play a vital role in machinery by ensuring smooth motion and reducing friction. Understanding load capacities, specifically static load vs...

Understanding bearing axial load, just like understanding different types of bearing load, is crucial for ensuring the proper functioning and...