Slewing Bearing and Jib Crane Bearing Guide

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...

Table of Contents

SKF bearings power critical applications from wind turbine gearboxes to EV powertrains, robotics, and medical systems.

As a global leader in precision bearing technology, SKF offers engineered solutions for performance, reliability, and efficiency.

This guide offers clear insights into SKF bearing types, selection tips, and sourcing—helping you choose with confidence.

Founded by Sven Wingquist, SKF Group supplies a wide range of precision SKF bearings and industrial parts globally.

From automotive to renewables, SKF worldwide facilities deliver wide assortment.

Key Figures:

"Are SKF bearings made in China? Are SKF bearings made in Italy?" The answer to both is yes—and far beyond.

The production bases of SKF bearings span across various regions worldwide.

SKF delivers precision ball bearings, roller bearings, slewing bearings and sealed units for robotics, automotive, and marine applications.

SKF bearings are famous for their advanced sealing, lubrication, and digital tools to optimize performance and reduce costs.

Which SKF ball bearing suits your needs best? Below is a quick guide to the main types, their features, and where they perform best.

SKF bearings, particularly deep groove ball bearings, like SKF 608 bearings, efficiently manage radial loads and moderate axial loads in both directions.

Key features:

Key applications:

These bearings are designed to handle both pushing (radial) and side (axial) forces.

SKF angular contact ball bearings come in three standard angles, each made for different jobs:

(Example: Power tools or small motors)

(Example: Factory conveyor belts)

(Example: Robot arms in assembly lines)

SKF angular contact thrust ball bearings are compact solutions for high-speed axial loads.

They're ideal for CNC machines, marine propulsion, and motor sport applications where vibration resistance and positional accuracy are critical.

SKF thrust ball bearings are for axial load applications exclusively.

They feature precision-ground washers and a ball-and-cage assembly to maintain strict axial alignment.

SKF self-aligning ball bearings that fix shaft misalignment.

This type of SKF bearings can adjust by up to 3 degrees because of their special round outer ring raceway.

The dual-row ball configuration maintains smooth rotation even under:

Key Industry Applications:

SKF Roller Bearings

Roller bearings support heavy radial loads with cylindrical, tapered, or ball-shaped rollers.

This type of SKF bearings are ideal for applications requiring high load-carrying capacity and stability under heavy loads.

Key Technical Features of cylindral roller bearings

Typical Applications

Key Technical Advantages of SKF tapered roller bearings:

Typical Applitcations

Design Advantages of SKF spherical roller bearings:

Typical Applications

SKF needle roller bearings have high load capacity for their small size.

They use accurate needle-shaped rollers that touch more surface, which makes them especially durable.

Typical Applications:

Table 1 Comparison Table of SKF Roller Bearings' Radial Load Capacities

|

Bearing Type |

Radial Load Capacity |

Design Features |

Typical Applications |

Key Advantages |

|

Cylindrical Roller Bearings |

★★★★★ |

Straight cylindrical rollers |

Gearbox shafts |

Extreme radial loads |

|

Spherical Roller Bearings |

★★★★☆ |

Barrel-shaped rollers |

Wind turbine main shafts |

Automatic misalignment compensation |

|

Tapered Roller Bearings |

★★★★☆ |

Tapered rollers |

Vehicle axles |

Precise preload adjustment |

|

Needle Roller Bearings |

★★★☆☆ |

L/D ratio >4:1 |

Transmission planetary gears |

Maximum space efficiency |

Technical Notes:

SKF Radial Spherical Plain Bearings have key features and applications as below:

Key Features:

Typical Applications:

Key Features of SKF linear bearings:

Industry-Leading Applications:

Among all SKF bearings, the special bearings are specialized for demanding applications like:

Super Precision Angular Contact Ball Bearings

Double Direction Angular Contact Thrust Ball Bearings (Super Precision)

.png?width=232&height=268&name=Fig%2014%20Double%20Direction%20Angular%20Contact%20Thrust%20Ball%20Bearings%20(Super%20Precision).png)

Super Precision Cylindrical Roller Bearings

Axial-Radial Cylindrical Roller Bearings (Super Precision)

.png?width=335&height=196&name=Fig%2016%20Axial-Radial%20Cylindrical%20Roller%20Bearings%20(Super%20Precision).png)

SKF Super Precision Clutch Release Bearings deliver ultra-smooth engagement for automotive transmissions.

These SKF bearings have accuracy down to the micrometer (a small unit) and use tough materials.

This guarantees the clutch operates precisely and lasts for a long time (with ways to monitor their condition).

Looking for SKF bearings with housing?

SKF mounted bearings Ready-to-install solutions with high-performance bearings and durable housings (including QT450).

Key Features:

Ideal Applications:

Key Features:

Applications:

Besides SKF bearings, SKF provides essential bearing accessories to enhance installation, maintenance, and performance for various industrial applications:

SKF bearings introduces cutting-edge bearing solutions including:

Are SKF bearings good? What are the advantages of using SKF bearings?

Here's what sets them apart:

Below are the screenshots of SKF Bearing User feedbacks:

SKF Bearing Applications Infographic

SKF spherical roller bearings last much longer than usual – about two and a half times longer.

Plus, they can handle extreme temperatures, from -40°C in the Arctic to +80°C in desert conditions, inside the main shafts of turbines.

From belt pulleys to EV transmissions, SKF tapered roller bearings reduce energy loss by 15% through optimized roller profiles.

SKF Explorer spherical rollers are extra tough and can work non-stop in crushers.

They turn out to last 18 months longer than the competition in copper mines in Chile.

SKF hybrid ceramic bearings (HYB series) reduce friction by 40%, ideal for vacuum pump applications.

LNG pump bearings operate reliably at -196°C, ensuring efficiency in energy transport systems.

Choosing the right SKF bearing starts with understanding your application’s needs. Here’s how to make smart SKF bearing selection decisions:

Need help? To quickly find the right SKF bearings, you can use the official SKF Bearing Selector or SKF Bearing Finder.

You can also check out LILY Bearing’s tools that help you match SKF bearings to other types, and get expert help.

You can also compare SKF bearings by size to narrow down the optimal fit.

Avoid these key issues when sourcing or evaluating SKF bearings:

You can find authorized SKF bearings distributors using the “Find a Distributor” tool on SKF’s official website.

Just enter your location to locate nearby SKF bearings suppliers.

And ensure you’re getting genuine SKF bearings with full technical support.

We advise you to search "SKF bearings near me" online. But verify if suppliers are authorized SKF bearing distributors for real SKF products.

Buy SKF bearings from the SKF Store (skf-us.ptplace.com) or Amazon.

Be careful who you buy from, because not all sellers are official SKF bearings dealers.

For the SKF bearings catalogue, refer to the official SKF website for full technical data.

A: Use proper tools (e.g., hydraulic nuts) and follow SKF’s Bearing Assist app for guided installation. For mounting, options include adapter sleeves, withdrawal sleeves, and locknuts. Regular maintenance includes frequent lubrication, seal checks, and vibration monitoring every 3–6 months or as recommended.

A: You should select SKF-approved greases (like LGHP 2) or oils based on load, speed, and temperature. Proper lubrication is critical to bearing life and performance.

A: SKF bearings are available in a wide range of sizes, materials, and precision classes. Most operate from –40°C to +150°C, with specialized options rated up to +350°C. You can find load ratings, tolerances, and design details in the SKF bearing catalogue.

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...

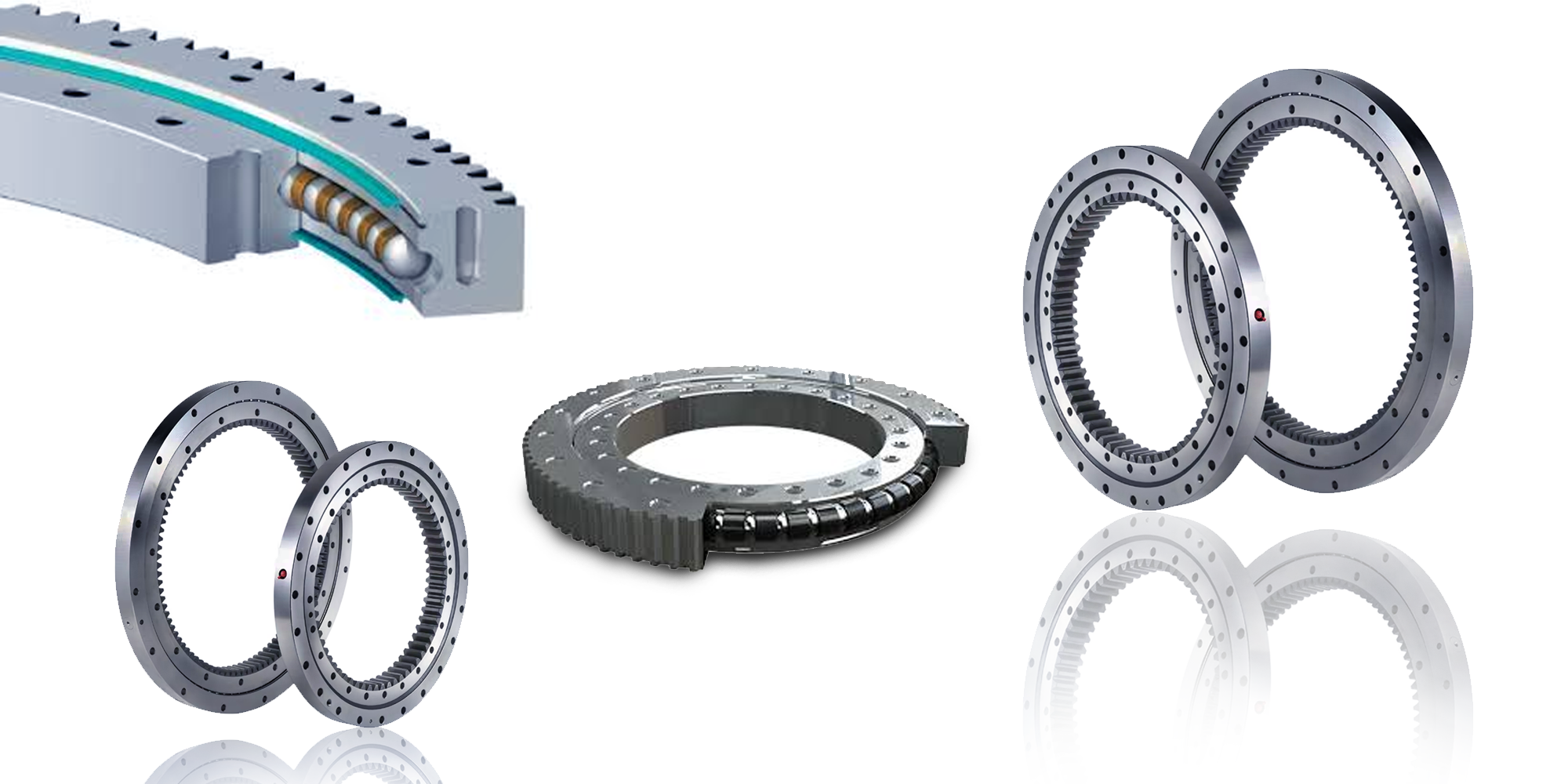

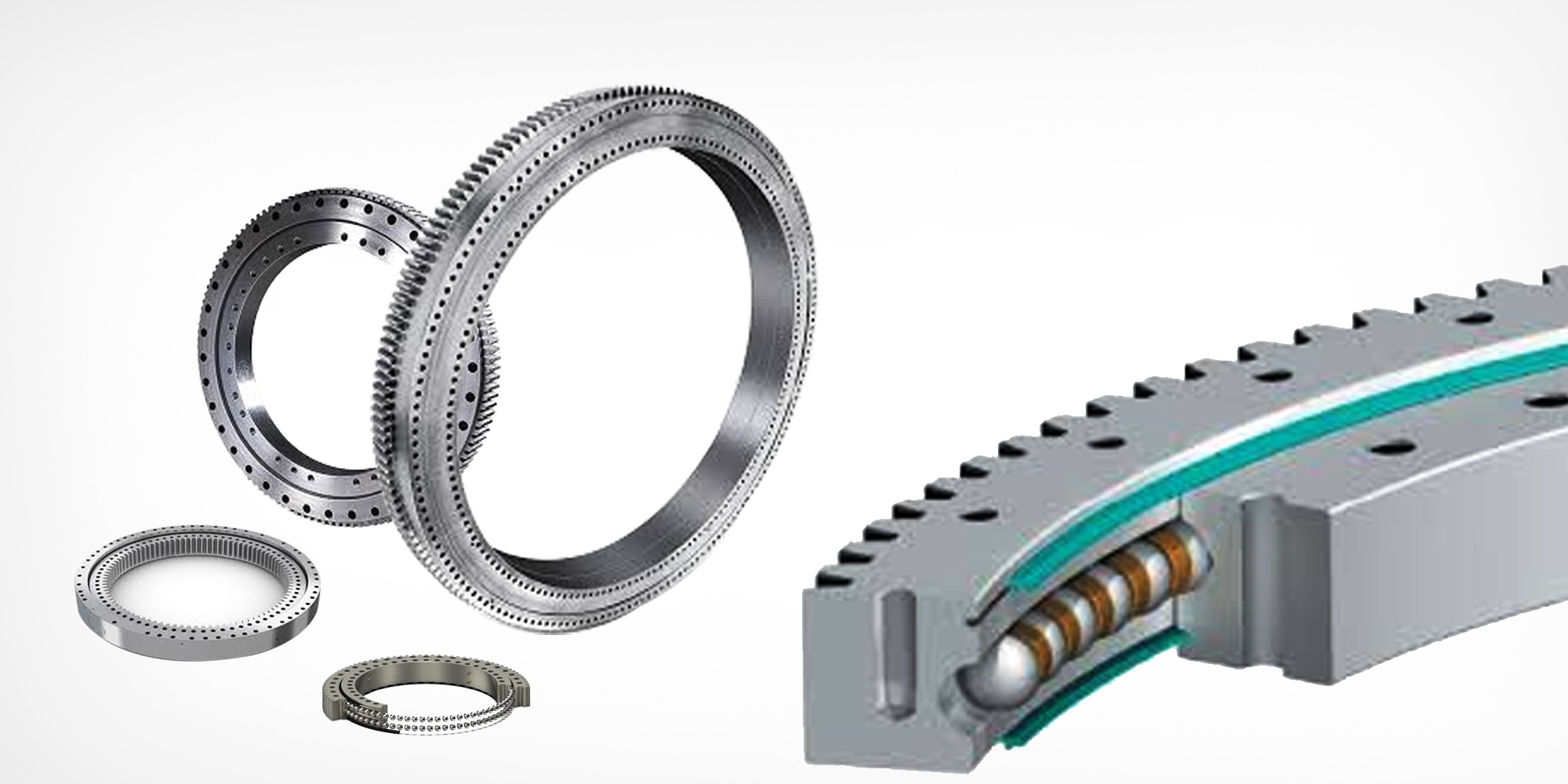

Slewing bearings, also known as slew bearing or slewing ring bearings, facilitate pivotal movement in machinery, handling axial, radial, and moment...

Bearings are essential components in nearly every machine, from aerospace systems to everyday appliances. They help reduce friction, improve...