What Is a Roller Bearing Used For?

Roller bearings are vital components in modern machinery. They play a critical role in ensuring smooth, efficient, and reliable operation across a...

In the modern industrial world, polyurethane rollers are key players. They help many processes run smoothly and efficiently, proving to be both robust and adaptable in a range of applications. In this blog, we will explore the unique features and benefits of polyurethane rollers, as well as their wide use in different sectors. Join us as we delve into the important role these rollers play in the industry.

Polyurethane rollers, made from polyurethane elastomer, bridge the gap between rubber and plastic. This elastomer is produced using isocyanates, including PPDI, MDI, TDI, and NDI. While these ensure robust thermal performance, NDI-based products might show a taupe color due to yellowing on light exposure.

Polyurethane, an engineering marvel, boasts of attributes suitable for roller applications. Key properties include:

A bearing coated with polyurethane to enhance durability, reduce noise, and ensure smooth operation.

A rotational mechanical device coated with polyurethane to improve grip, reduce wear, and provide consistent performance.

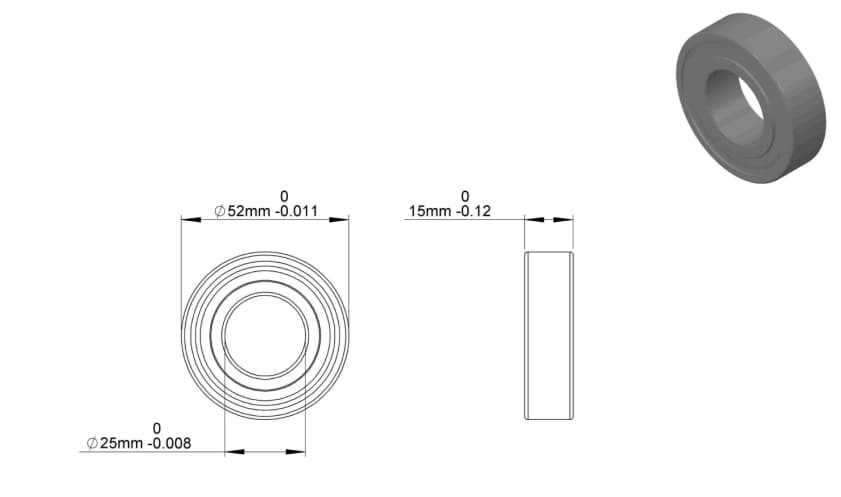

A bearing coated with Polyoxymethylene (POM), known for its low friction and high stiffness, offering stable performance.

Polyurethane Coated Bearing With Screw:

A polyurethane-coated bearing that comes with a screw, making it easier to integrate into specific applications.

Polyurethane Coated Cam Followers/Track Rollers:

Rollers or followers designed for cam mechanisms, coated with polyurethane to ensure longevity and smooth movement.

A bolt designed to stop or limit movement in mechanical setups, ensuring precision and safety in operations.

We also provide Outsourcing Polyurethane bearings and Outsourcing POM bearings.

The durability of Polyurethane Rollers is evident in these key areas:

Polyurethane rollers excel in supporting heavy loads. Their strength comes from:

Polyurethane rollers offer enhanced durability, minimizing replacements and reducing maintenance downtime, thereby boosting productivity.

Polyurethane rollers are FDA-approved for food processing, ensuring food safety. They're a better choice than rubber or plastic options.

Rubber roller linings add carbon black as filler and reinforcement. When rolled on hard surfaces with enough force, they can leave dark streaks and marks that can cause damage in applications such as finished product handling and printing. Polyurethane rollers, on the other hand, do not require a carbon roller liner for additional support, which avoids the possibility of carbon black.

Polyurethane is easier and cheaper to manufacture than most other materials and can reduce downtime and the need for repairs and replacements due to its high wear resistance and long service life.

Applications of Polyurethane Rollers Across Industries, such as:

Looking for the right polyurethane roller? Keep these simple tips in mind:

With these points, finding your perfect polyurethane roller becomes easy and straightforward.

Roller bearings are vital components in modern machinery. They play a critical role in ensuring smooth, efficient, and reliable operation across a...

Slewing bearings are essential parts in modern machinery. They play an important role in a wide range of industries. These large bearings can hold a...

In the world of engineering and manufacturing, ceramic balls , found in ceramic bearings are becoming key components in many industries. They're...