6204 Bearing: 20mm X 47mm X 14mm Deep Groove Design

The deep groove 6204 bearing is a staple in the machinery world, prized for its versatility and reliability. This blog post delves into the specifics...

Bearings play a pivotal role in ensuring the smooth operation of various machinery, including skateboards. Cleaning these tiny components not only boosts their performance but also prolongs their lifespan. In this guide, we'll zero in on how to clean bearings, especially those in skateboards.

Bearings play a pivotal role in a multitude of applications, acting as intermediaries that reduce friction between moving parts, thereby facilitating smoother motion. Whether in vehicles, machinery, or our focus here, skateboards, their primary function remains consistent — to support loads and enable parts to rotate or slide effortlessly.

However, the presence of dirt and debris compromises this function. Dirty bearings not only hinder performance by causing resistance and uneven movements but also escalate wear and tear. This deterioration can lead to unexpected failures, posing potential safety risks. In essence, the cleanliness and maintenance of bearings are paramount to both performance and safety in any application.

For a general understanding of how to clean bearings, follow these steps:

Skateboard bearings are vital for a smooth ride but face challenges like exposure to dirt, moisture, and consistent stress. Their placement makes them vulnerable to external elements:

Given these hurdles, maintaining skateboard bearings is essential:

In essence, regularly cleaning skateboard bearings ensures a superior, safe, and cost-effective skateboarding experience.

Whether you're a seasoned skater or just starting, maintaining your skateboard bearings is essential for a smooth and safe ride. Over time, bearings accumulate dirt, dust, and grime which can significantly hamper performance. By following this detailed guide, you can ensure that your bearings are in top condition and extend their lifespan.

Prior to cleaning skateboard bearings, ensure you have the following materials ready:

Start by using your skate tool or wrench to remove the axle nuts, then slide the wheels off the truck axle. Remember to account for the washers positioned between the axle nuts and the inside of the axle. It's advisable to place these axle nuts and speed washers in a small tray to avoid misplacing any tiny components.

Utilize the truck's axle to extract the bearings from the wheels. Position the wheel halfway onto the axle's end, ensuring only one bearing is on it. Twist the wheel outward, leveraging the bearing out. Turn the wheel and repeat for the opposite bearing.

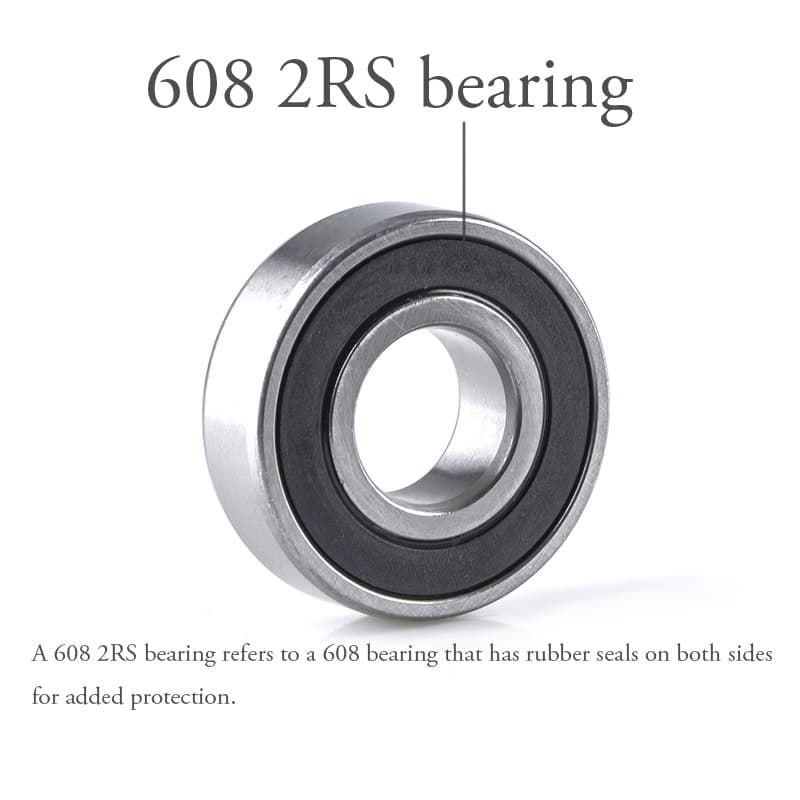

To access the inner parts, remove the bearing shields or seals. For rubber sealed bearings, gently use a razor blade, thumbtack, or safety pin. Ensure you don't deform the seal to avoid friction upon reassembly. Safely store the seals in your hardware tray.

For metal shielded bearings, detach the “C” clip from the outer race. Whether Shielded or Sealed Bearings, exercise caution during disassembly.

Some bearings allow removal of the balls and bearing retainers or cages for cleaning, but it's often not advised.

Wipe each bearing with a dry cloth or paper towel to remove larger dirt particles and old lubricant.

Place the bearings in a container with a lid, pour in enough solvent to cover them, and seal the container. Shake gently for several minutes, allowing the solvent to dissolve the grime.

After soaking, take each bearing out and use a soft brush (an old toothbrush works well) to scrub away any residual dirt. Pay special attention to the ball bearings and the raceways.

Once clean, rinse the bearings with some fresh solvent to wash away loosened dirt and the old solvent. Gently tap the bearings face-down on a cloth or paper towel. To expedite drying, use compressed air or a hair dryer, ensuring you blow air from both sides to push out any trapped liquid.

Use a skateboard-specific lubricant for this step. Avoid household oils and WD-40 as they can attract more dirt. Apply 1-2 drops to each bearing and spin them to distribute the lubricant evenly.

Reattaching the bearing shields is straightforward. Simply align, press from the center, and ensure they snap securely. These shields protect against external contaminants during rides. Before reinstalling bearings to the wheels, remember to place any bearing spacers for weight distribution. If using speed washers, position them on the truck axle before securing the axle nuts, ensuring smooth bearing movement and minimizing wear. Now, your skateboard is primed for a rejuvenated ride.

When cleaning skateboard bearings, it is essential to choose suitable cleaning solutions, avoiding harsh chemicals that might damage the bearings. Establishing a regular cleaning schedule will help in maintaining optimal performance, and gentle handling will prevent unnecessary wear and tear. Lastly, proper storage of cleaned and lubricated bearings in a dry, clean environment is vital to prevent contamination. These best practices will ensure effective cleaning, resulting in a smoother skateboarding experience and extended bearing life.

Regular maintenance not only prolongs the life of the bearings but ensures a smoother ride. We urge all skateboard enthusiasts to prioritize this process and harness the full potential of their gear.

The deep groove 6204 bearing is a staple in the machinery world, prized for its versatility and reliability. This blog post delves into the specifics...

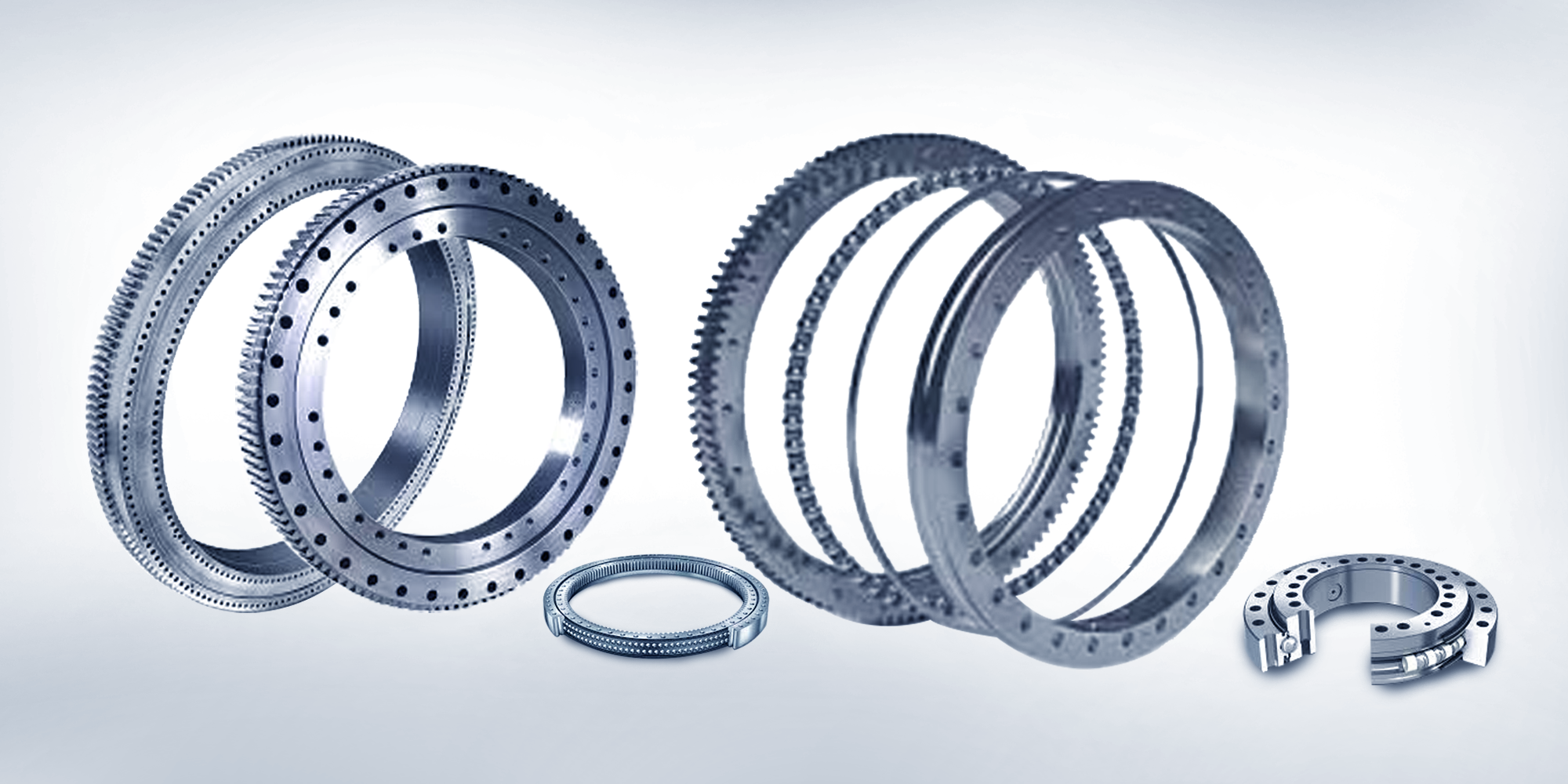

Slewing bearings, sometimes called slewing rings, slewing ring bearings, or turntable bearings, play a key role in machines that need to spin...

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...