An Overview of Small Bearings

Small bearings play a crucial role in both modern industrial and domestic appliances. These bearings, despite their minute size, significantly...

Bearing speed is vital for machinery efficiency and durability. Its capacity is often measured by its operating temperature. Excessive friction heat indicates potential overreach in rotational speed, which can lead to failures like seizures. Beyond temperature, some bearings have inherent mechanical limits influencing their speed. This article delves into the importance of bearing speed, its relation to temperature, and the role of mechanical constraints.

Navigating the complexities of bearing capabilities often leads professionals to bearing product tables. These tables illuminate the speed boundaries bearings can safely operate within. Let’s succinctly break down the key speed ratings:

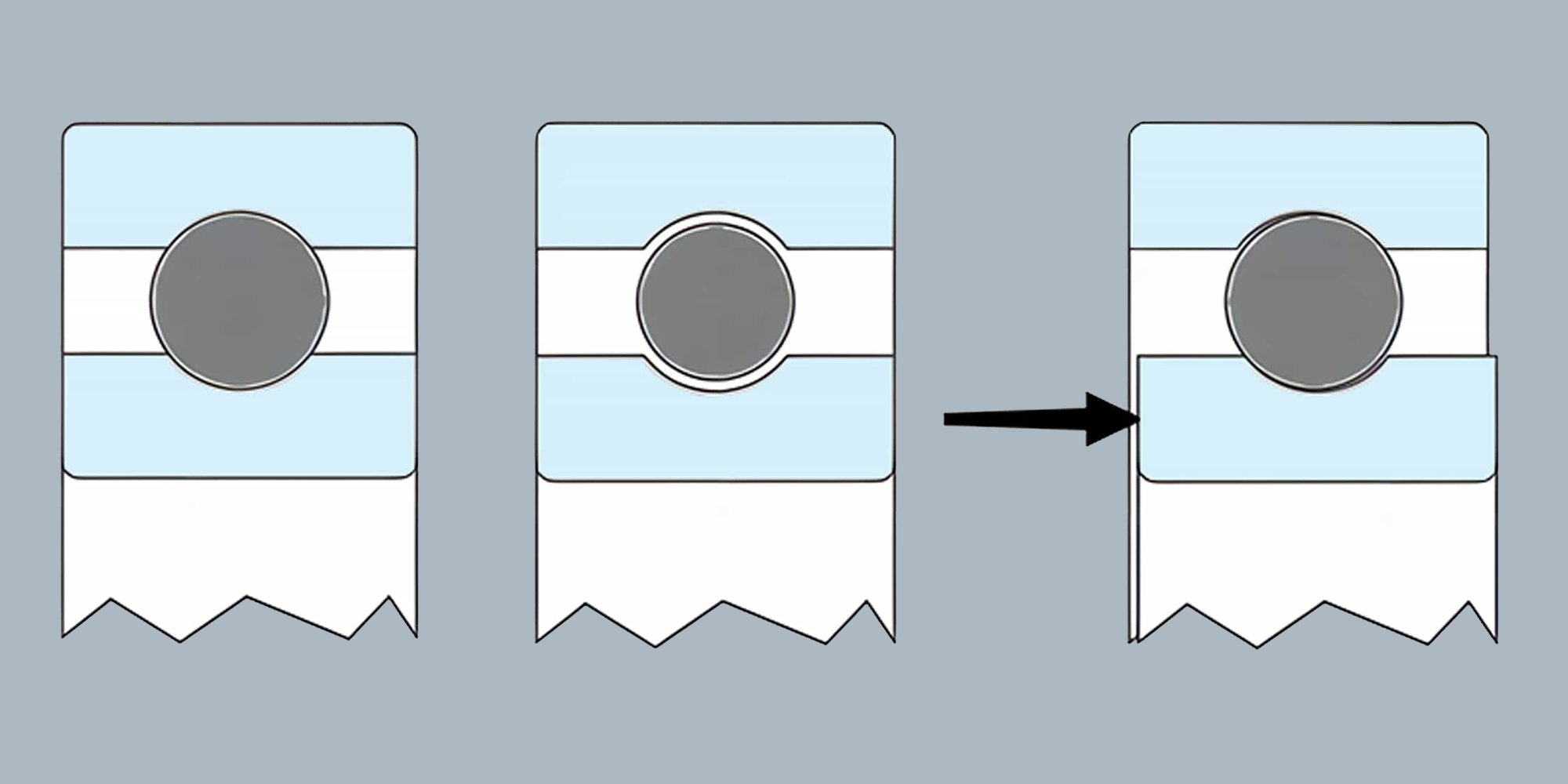

Bearings with contact seals predominantly rely on their limiting speed to determine their maximum bearing speed . Unlike other types of bearings, they often don't feature reference speeds in product tables. The presence of seals, while offering protection from contaminants, influences the bearing speed due to the added friction. Thus, understanding this balance is crucial for their efficient use.

The ISO 15312 standard provides specific guidelines for determining the reference speed of a bearing, ensuring that engineers and users can make informed decisions about bearing speed capabilities.

The ISO reference speed is strictly valid for open bearings. They should have:

Sealed bearings don't have specified reference speeds in most product tables due to the specific challenges posed by seals, including increased friction and potential for heat buildup.

The ISO standard does not define reference conditions for sealed bearings.

This standard, originally formulated for oil lubrication, extends to grease lubrication under the specification that it employs a lithium-based grease with a mineral oil base possessing a viscosity ranging between 100 and 200 mm²/s.

Under grease lubrication, bearings may experience a peak in temperature during the initial start-up phase. This necessitates a running-in period for the bearings to achieve a steady-state operating temperature, ensuring optimal functionality and longevity.

Understanding the adjusted reference speed is key in bearing applications, providing a more tailored approach than the standardized ISO reference speed.

The product tables highlight a defined limiting speed for standard bearing configurations. This speed should not be surpassed unless modifications are made to the bearing design to accommodate increased velocities. To effectively harness the bearing's limiting speed:

Proper lubrication is paramount. As one nears the upper speed threshold, transitioning to oil lubrication might become necessary.

Several factors dictate the speed boundary:

When considering open ball bearings, it's vital to note that their design and structure might necessitate specific considerations with regard to their limiting speed.

Operating a bearing beyond its standard speed limits demands precision and careful analysis. Before proceeding:

Conduct a thorough evaluation to understand the bearing's tolerance to increased speeds.

Temperature Management: Implement additional cooling to offset the rise in bearing temperature.

In essence, exceeding bearing speed limits is possible, but it mandates a calculated and attentive approach.

Adhering to bearing speed limits is crucial for both optimal performance and safety. When contemplating higher speeds, necessary safety precautions must be in place. Such diligence ensures the longevity and consistent operation of bearings. At Lily-bearing, we emphasize the significance of these limits, offering products that prioritize enduring performance and safety.

Small bearings play a crucial role in both modern industrial and domestic appliances. These bearings, despite their minute size, significantly...

Bearings are crucial components in the mechanical world, helping rotating equipment run smoothly and efficiently. Preloading a bearing is an...

Slewing bearings, also known as slew bearing or slewing ring bearings, facilitate pivotal movement in machinery, handling axial, radial, and moment...