Cam Follower VS Roller Follower

Cam followers and roller followers are essential parts in machines that change spinning movements into sliding ones. These parts are essential in...

Cam followers play a key role in many machines, helping to change spinning motion into straight-line movement.

Understanding what makes cam followers fail and what to look for is crucial for keeping your machines in tip-top shape. By identify bad cam follower symptoms early, you can save a lot on repairs and keep your production lines rolling.

Our blog guides you to explore the common reasons behind cam follower failures. We share real-life cases and offer tips to prevent cam follower failures.

Cam followers, or tappets, help things slide easily along the camshafts in engines. The cam lobes on these shafts work with the followers to control when the engine valves open and close just right.

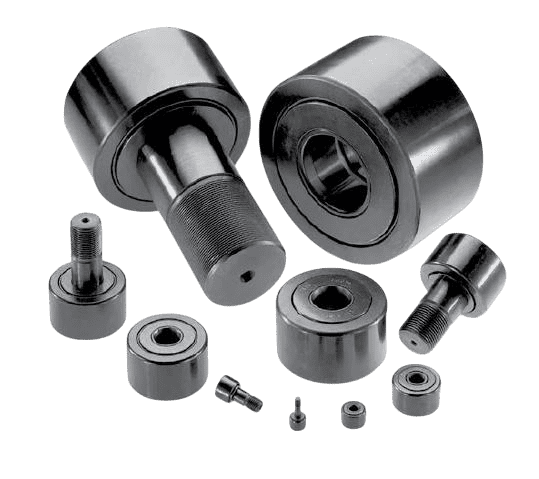

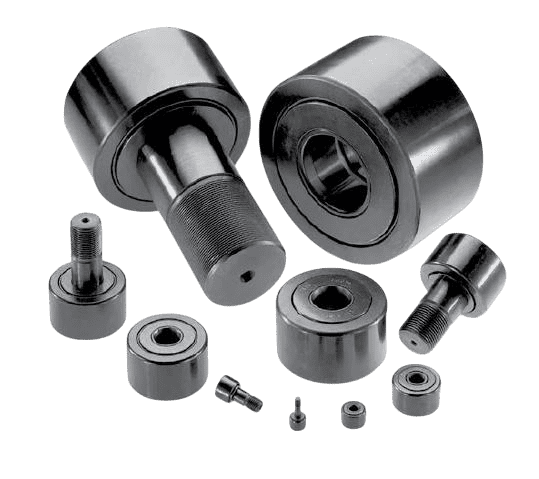

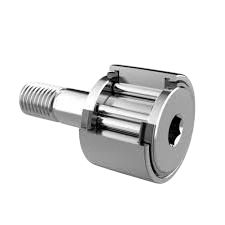

They consist of a roller, a shaft, a bearing assembly and lubrication paths. The roller contacts the cam, the shaft aligns with the valve stem, and the bearing assembly facilitates motion. The lubrication paths reduce wear.

Cam followers do important jobs in several fields.

Repeated motion and high loads on cam followers cause metal fatigue, leading to surface pitting. Over time, friction and heat damage wear down components.

This gradual damage can weaken bearing parts until they fail. This is why you need regular maintenance practices to catch such mechanical wear and tear before complete breakdown.

Not enough oil or dirty oil can make parts rub more, creating more heat and camshaft wear. Oil quality and frequency can also affect cam followers.

High-quality lubricants reduce this wear, keeping components cool and extending their service life.

Improper installation or bearing misalignment puts uneven stress on cam followers. This can cause uneven wear and tear, making them wear out faster.

In automotive, a misaligned camshaft can stress followers. In factories, an off-kilter conveyor's misalignment can over-stress bearings, leading to early failure in both cases.

Using cheap materials and poor workmanship can make cam followers less sturdy.

Defects can happen when parts become brittle because of wrong heat treatment. Rough bearings can create extra friction. Parts may not fit well because of tolerance problems. All these make them less durable and reliable.

When a cam follower is overloaded or experiences sudden impacts, it can suffer damage. This could mean premature wear, deformation, or even breaking. This leads to problems like reduced engine power, noisy operation, and, in severe cases, engine failure.

Think about heavy machinery under heavy stress, or car engines pushed to their limits. A sudden shock can shatter the cam follower in a machine, bringing it to a halt. In cars, constant overloading wears down the cam follower, making the engine less efficient and increasing pollution.

In VW and Audi models, automotive tappet issues in high-pressure fuel pump systems can lead to severe damage. As the cam follower (tappet) wears out, it allows metal fragments to enter the fuel pump. This may cause cam follower failure and potentially damaging the camshaft.

High-pressure fuel pump failure often requires costly repairs or replacements. This justifies the need for regular inspections to prevent such failures.

In heavy machinery, cam followers often suffer from overloading, which wears them out early and can change their shape. Indeed, without regular maintenance, cam followers can become misaligned and accumulate dirt and debris.

Besides, without enough lubrication, they will be subject to friction and wear. This makes the machines less dependable and shortens how long they last.

For CNC machines and robots, getting the right amount of lubricant and being lined up just right is extremely important.

Small mistakes, like not enough machine lubrication or slight misalignment, can cause major problems quickly. This can lead to serious wear or breakdowns.

Without proper alignment, the movements may not be exact, and that can lead to the whole system stopping.

Even tiny errors can cause more serious problems because high-precision work doesn't allow for much wiggle room.

Checking your equipment regularly is key to spotting small issues like wear, being out of place, or needing more oil. By fixing or cleaning things on time, you stop little troubles from turning into serious breakdowns.

When you service your machinery, look for signs of wear on the cam followers. Make sure everything is in proper alignment. And check that there's enough lubricant to keep things running smoothly and dependably.

Pick the lubricant that's just right for what you're using it for—whether it's for automotive, large machines, or precision systems.

Putting on the wrong kind of lubricant can cause parts to wear out more quickly. Maintaining the cleanliness of your lubricant is essential. Store it in a clean, dry location, free from any dirt that could potentially compromise its purity.

When apply a lubricant, use clean tools to keep your machines in perfect shape and make them last longer.

To get your cam followers in place just right, stick closely to the instructions the manufacturer gives. Use precision tools to make sure components are in correct positions.

Hiring professional installers can save you money. This way you can reduce pricey errors and keep your machines running at their best. Professionals know how to line the parts up accurately, which helps avoid breakdowns.

Cam followers can break down because of wear, not enough lubrication, poor alignment, flaws or overloading.

Proactive upkeep, top-quality bearings, and expert installation keep your gear in tip-top shape. Grasping how the parts fail helps you sidestep breakdowns, saving time and money while boosting output.

If you need help figuring out what's wrong or fixing cam follower failures, consider getting in touch with LILY Bearing.

Cam followers and roller followers are essential parts in machines that change spinning movements into sliding ones. These parts are essential in...

In the industrial sector, machines that work well all the time are essential for good performance and safety. McGill cam followers are just a crucial...

Cam follower bearings provide smooth linear movement as the cam rotates, which minimizes wear better than sliding contacts. This blog explores the...