Understanding Radial Load: A Key Factor in Motor Bearing Sizing

Motor bearing sizing is paramount to the functionality and longevity of a motor. Choosing the right bearing ensures efficient motor operation, while...

In the world of mechanical engineering, the tilting moment of slewing bearings are key to how machinery runs and how long it lasts.

It happens when there are forces acting on the bearings in systems that turn.

If we don't pay attention to these moments, it can lead to machines not working well, safety problems, and bearings wearing out faster.

This article talks about why it's so important to figure out the tilting moments in slewing bearings of construction equipment, wind turbines, and robots.

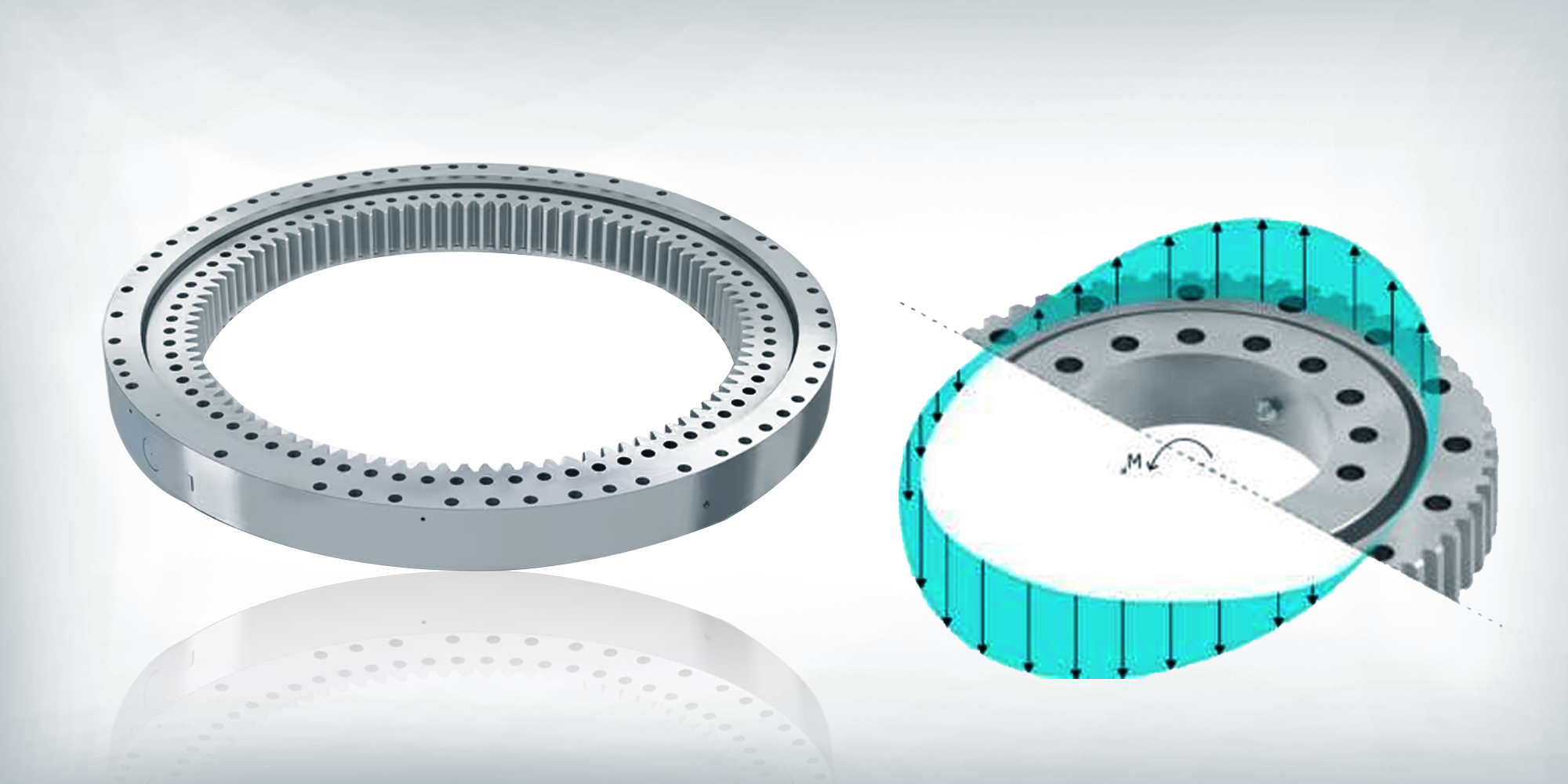

Slewing bearings, sometimes called turntable bearings or slewing ring turntable bearings, are made to deal with different kinds of forces: axial, radial, and moment loads.

These bearings are what let machinery spin all the way around, such as in cranes, excavators, and wind turbines.

In slewing bearings, a tilting moment is the twist that happens when the load isn't exactly on top of the bearing's middle.

This moment can cause the bearing to tilt, leading to uneven load distribution and potential damage.

Axial and radial moments are forces that either run along the bearing's axis or push against it straight on.

On the other hand, a tilting moment is a force that comes in at a slant, kind of like a sideways push.

If you don't handle this force just right, it can make the bearing go out of whack.

The tilting moment (Mt) can be calculated using the formula: Mt=F×d

where F is the force applied at a right angle to the axis of rotation, and d is the distance from the center of the bearing to the point of force application.

Let's walk through a real-world example of calculating the tilting moment for a slewing bearing in a crane.

We'll also discuss potential challenges and considerations in the calculation process.

Example: Calculating Tilting Moment for a Crane's Slewing Bearing

If a slewing bearing has to deal with too many tilting moments, it can cause a lot of stress, wear out faster, and not last as long.

To avoid this, pick the right bearing, make sure the structure is well-designed, and do regular maintenance.

By spreading the load out evenly and keeping tilting moments to a minimum, you can make the machinery more dependable and efficient.

Tilting moments reduce machine efficiency by increasing energy use due to the extra force needed to counteract them.

They also cause vibrations that decrease accuracy and speed up part wear.

Additionally, they can lead to imbalances, putting more stress on bearings and gears, which further increases energy consumption and wear.

Tilting moments can be dangerous because they might cause machines to break down, lead to accidents, or make the equipment wear out faster.

To keep things safe and running smoothly, it's important to:

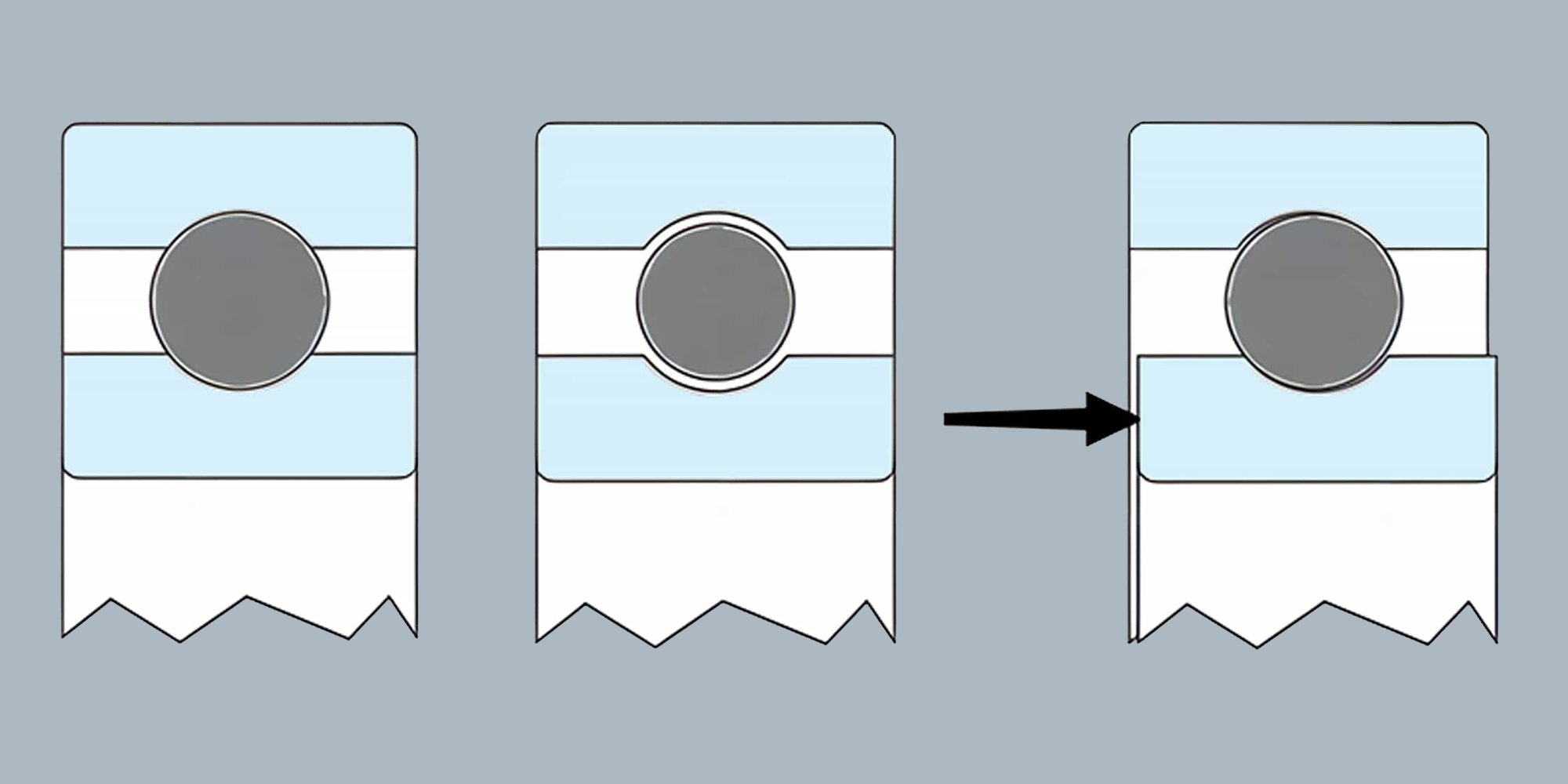

When choosing slewing bearings for high tilting moments, consider factors like load capacity, rigidity, and material strength.

For heavy-duty applications, opt for cross roller bearings excel because they are better in rigidity and load distribution.

In contrast, four-point contact bearings good at staying steady even when things aren't perfectly lined up and under varying loads.

Choose the right bearings for your needs so your machinery works well and lasts longer.

Making the structure around the machinery really matters for reducing those tilting moments.

It helps keep the parts in good shape and extend equipment life.

Good design means balanced load distribution, precise alignment to ensure forces act centrally, and the incorporation of self-aligning mechanisms that can fix themselves if things get a little off-kilter.

Making the structure strong and adding extra support also helps counteract tilting forces, enhancing overall stability and efficiency.

To keep slewing bearings from getting too much tilting stress, follow these steps and use the monitoring methods listed:

Cranes and excavators can have tilting moments because of dynamic and uneven loads.

This might lead to potential misalignment and structural stress. To handle these issues, try these solutions:

In wind turbines, tilting moments in slewing bearings are caused by uneven wind-related and gravitational forces.

These moments can reduce bearing life and turbine efficiency.

The wind energy sector addresses this issue with strategies such as:

Understanding how to handle tilting moments in slewing bearings is of great importance. It helps to improve functionality, safety, and longevity.

At LILY Bearing, we encourage our customers to consider tilting moments during the planning and maintenance phases of their equipment.

For specialized solutions or expert advice, reach out to LILY Bearing — your go-to for top-notch bearings.

Motor bearing sizing is paramount to the functionality and longevity of a motor. Choosing the right bearing ensures efficient motor operation, while...

Bearings are crucial components in the mechanical world, helping rotating equipment run smoothly and efficiently. Preloading a bearing is an...

Bearings play a crucial role in factories and other heavy-duty settings. They help machines move more easily and last longer by reducing friction. ...