What Are the Three Main Types of Mounted Bearings?

Mounted bearings are vital for keeping industrial machines running smoothly. They support rotating shafts, align them properly, reduce friction, and...

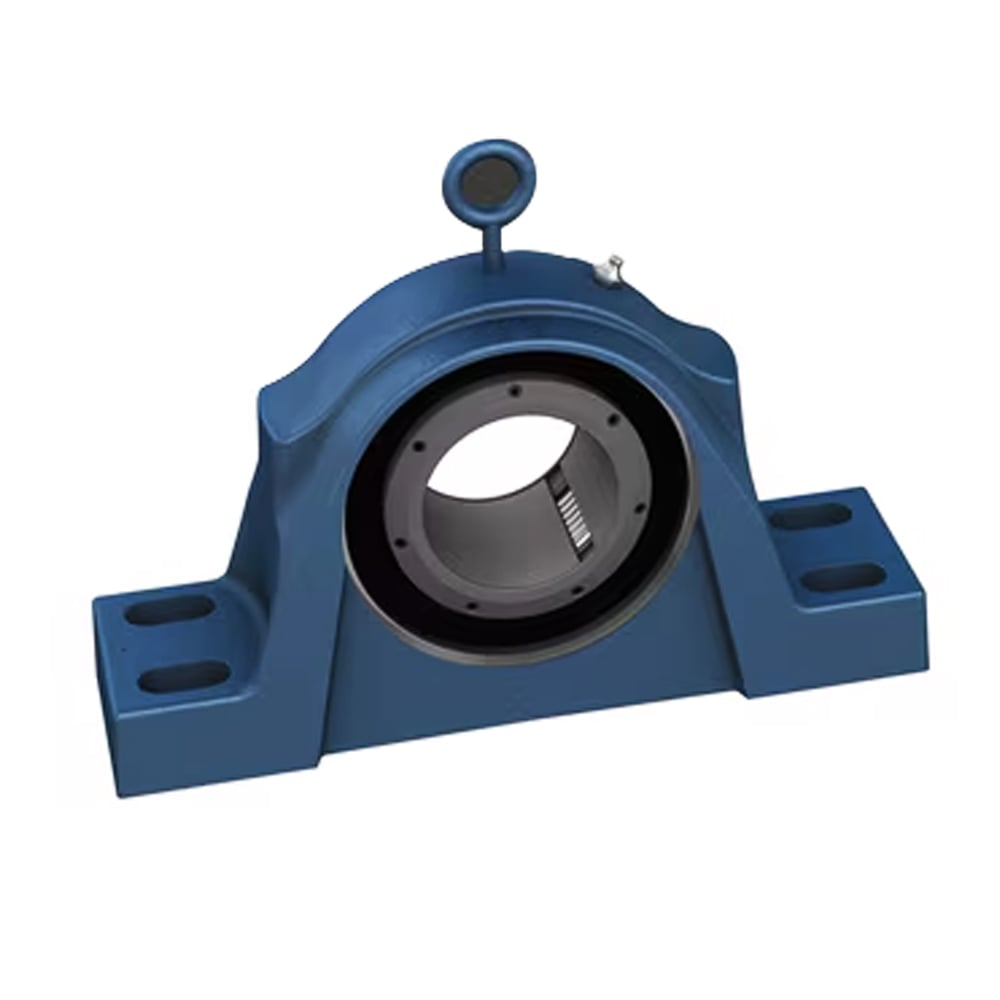

Mounted bearings are essential for industrial machines. They support and stabilize rotating shafts, ensuring they stay aligned and reduce friction. This helps machines run smoothly and efficiently. Flange mounted bearings are especially useful due to their unique design and versatile uses.

Flange mounted bearings, also known as flange mount bearings, are a type of mounted bearing that features a flanged housing with a preassembled sealed bearing.

This design allows the bearing to be securely mounted perpendicular to the shaft axis, providing robust support and alignment.

The flange can have two, three, or four mounting holes, depending on the specific style, making these bearings adaptable for various installation requirements.

Based on Housing Style

These bearings are diamond-shaped with two mounting holes, one on each side of the bearing. The mounting holes form a straight line through the axis of the bearing, providing a compact design suitable for medium load applications.

These bearings have three mounting holes arranged either radially around the bearing axis at 120 degrees or on a triangular flange offset from the bearing axis. This design offers a sturdier mount and better load distribution.

These bearings have four mounting holes arranged around the bearing axis and usually come in round or square housings. They offer maximum strength and support, making them perfect for heavy-duty applications.

Based on Rolling Elements

Bearings used in flange mount housings are known as insert bearings. Various types of bearings can be used in these housings, depending on the application and operating needs.

Plain Bearings and Sleeve Bearings:

Flange mounted bearings are used in many industries because they are versatile and reliable. They are particularly beneficial in applications where the bearing must be mounted on a flat surface or at the end of a shaft.

Common uses include:

The housing of flange mounted bearings can be made from different materials, each best for certain uses:

Understanding both static and dynamic load requirements is crucial when selecting flange mounted bearings. These bearings must handle radial and axial loads effectively to prevent deformation or premature failure. Evaluating the load capacity ensures that the bearings can support the operational stresses of the application.

When selecting a bearing, it's important to consider its size:

The operational speed of the machinery is another critical factor in bearing selection. Bearings must be compatible with the machinery's speed to maintain performance and longevity. High-speed applications may require specific types of bearings designed to reduce friction and heat generation.

The operating environment significantly impacts the design and material selection for flange mounted bearings. Bearings exposed to harsh conditions, such as extreme temperatures, humidity, or contaminants, need materials with strong sealing and corrosion resistance to prevent premature failure.

Ease of maintenance and durability are important considerations. Bearings designed for easy inspection and replacement help reduce downtime and maintenance costs. Features like split housing and protective covers enhance the bearing's durability and extend its service life.

With various flange configurations available, such as two-bolt, three-bolt, and four-bolt designs, these bearings offer flexibility in mounting. The mounting holes in the flanges allow for easy installation and provide a secure attachment that can withstand the forces generated during operation.

Flange mounted bearings are vital for industrial machines. They support and stabilize rotating shafts, keep them aligned, and reduce friction. This helps machines run smoothly. LILY Bearing offers various types, including mounted bearing units, mounted bearing inserts, corrosion protection bearing units, and corrosion protection bearing inserts, providing reliable solutions for many applications.

Mounted bearings are vital for keeping industrial machines running smoothly. They support rotating shafts, align them properly, reduce friction, and...

In the world of machinery, mounted bearings play a pivotal role. They are integral to the smooth operation of various equipment across industries....

Mounted bearings are pre-assembled units that combine an insert bearing (such as a ball or roller bearing) with a housing. They are designed to...