Characteristics, Uses and Advantages of Stainless Steel Bearings

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...

Bearings play a crucial role in factories and other heavy-duty settings. They help machines move more easily and last longer by reducing friction. McGill Bearings, a prominent name in the industry, is known for its legacy of innovation.

This blog aims to provide you a look at the past of McGill Bearings. It points out how the brand has made a big difference in helping factories and machines work better.

In 1905, James H. McGill established the Crescent Company in Chicago. It focused on electrical products like lamp guards and cord spools.

The business moved to a new spot in Valparaiso, Indiana. In 1910, they renamed themselves as McGill Manufacturing, which marks a new page in their story.

In 1935, McGill engineers made a huge breakthrough in their field. They invented the first roller bearing cam follower, which was a game-changer compared to the old-fashioned bearings. This new idea gave birth to the CAMROL® series, making their bearings perform better and dependably. It set a new benchmark for bearing making.

Expansion of the Bearing Product Line

McGill added MULTI-ROL® needle bearings to its product range in 1930 and the GUIDEROL® needle bearings in 1956. They are suitable for heavy lifting and high precision.

The company kept growing, adding in 1967 and LAMBDA® seals later on. This proved that they were dedicated to creating fresh ideas and tailoring solutions to meet the unique needs of different industries.

McGill bearings are widely used in many different fields because they are precise and dependable.

They help vehicles run better and last longer. Airplanes count on them to handle heavy loads and be extremely precise, which is a must for flight safety.

In the food and drink business, these bearings don't rust and follow the rules set by the FDA. They help to keep machines clean and running smoothly.

For textile industry, McGill bearings are great at dealing with the fast pace and constant use needed in making fabrics.

As we all know, McGill makes strong, trustworthy, and innovative bearings that can handle challenges of each industry.

In 1990, Emerson Electric Company acquired McGill Bearings, which was a major step in their journey. This meant that McGill became a key part of Emerson Power Transmission Corporation. When Emerson started selling McGill's really good bearings along with their other industrial stuff, they were able to sell to more people and give them more choices.

In 2015, Regal Beloit, which later became Regal Rexnord, acquired McGill Bearings. This was a new beginning for McGill.

By joining Regal Rexnord's family of brands, McGill kept making great, advanced bearings. With Regal Rexnord's support, McGill has stayed a key player in the industry. The company has been focusing on making reliable and creative bearing technology.

McGill Bearings a history about coming up with new ideas:

1930: They started making MULTI-ROL® needle bearings, which are solid enough to handle heavy loads.

1937: They launched CAMROL® cam follower bearings, which changed how we control movement with better precision and trustworthiness.

1956: They introduced GUIDEROL® needle bearings, which are great at handling still loads and are especially sturdy.

1967: They came out with SPHERE-ROL® spherical roller bearings, which can handle a lot, move fast, and even tolerate misalignment.

These new ideas have helped meet the changing needs of industries, from handling heavy loads to making machines work more precisely. They've greatly changed the landscape of industrial bearings.

McGill plays an important role in the can making industry. They make special cam follower solutions just for this industry. Their bearings can work well in the tough conditions of fast can-making lines, where reliability and precision are a must.

McGill can design bearings that can handle unexpected forces, go fast, and deal with dirt or other things that might get in the way. These are common problems in in severe duty applications. McGill is the first choice for industries needing custom bearings that work well even under extreme conditions, because they can tweak their designs to suit each specific task.

McGill has made big strides in bearing technology. They've come up with innovations like the LUBRI-DISC® seal, which keeps dirt out and grease in, making bearings last longer. They've also made bearings stronger to handle heavier loads, which is a game-changer for tough industrial jobs.

McGill uses high-quality materials to make their bearings and subjects them to special heat treatments. This helps them work well even in tough situations, which means they break down less often and don't need as much fixing.

Their bearings are easy to put in and take care of, which helps customers run their machines and tools more smoothly.

In simpler terms, the new technology and cool products from McGill have made their bearings better. This has helped businesses all over the world by making their production faster and their operations more dependable.

McGill Bearings is known for making highly quality and long-lasting products. They're famous for being reliable in all sorts of different industries. People have faith in their well-crafted products to perform perfectly, no matter how tough the situation or how demanding the task.

McGill Bearings are a go-to choice for tough machines in industries automotive, aerospace, and food processing. These sectors rely on McGill's bearings for their heavy-duty machinery and equipment where failure is not an option. This consistent reliance underscores the brand's commitment to excellence and durability in engineering and manufacturing.

People can always count on this brand because it shows its commitment to making things that are both really good and built to last.

McGill started as a small electrical products company and grew into a leading name in bearings. The brand is well-known for coming up with new ideas, making high quality products and being dependable.

If you're looking for bearings that have similar high performance, LILY Bearing has options that can replace McGill Bearings. To learn more and see what else we offer, just contact your experts in LILY Bearing.

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...

Bearings are essential parts of machines and equipment. They reduce friction, making it easier for parts to move smoothly. Two main types of bearings...

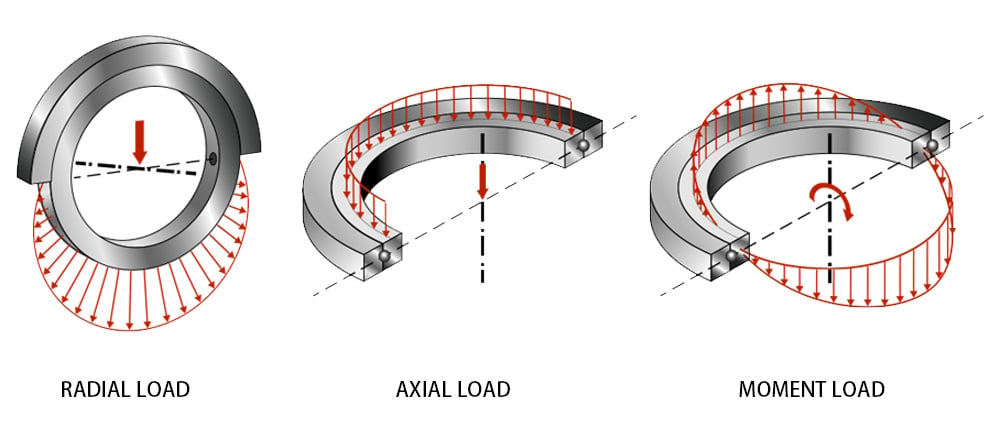

slewing ring bearings, or slewing bearings, are a fundamental component in numerous industrial machines, particularly in the renewable energy sector....