Bad Cam Follower Symptoms

Understanding Bad Cam Follower Symptoms The engine, often referred to as the heart of a vehicle, depends on several components to run smoothly. ...

5 min read

Erik : Aug 27, 2025 3:42:39 AM

Bearings are important parts in machines that help things move smoothly. They reduce friction, which makes them easier for parts to slide or roll. Bearings also support weight, helping to carry the load of moving parts and keeping them in the right position. This helps machines work better and last longer.

Some Types of Bearings

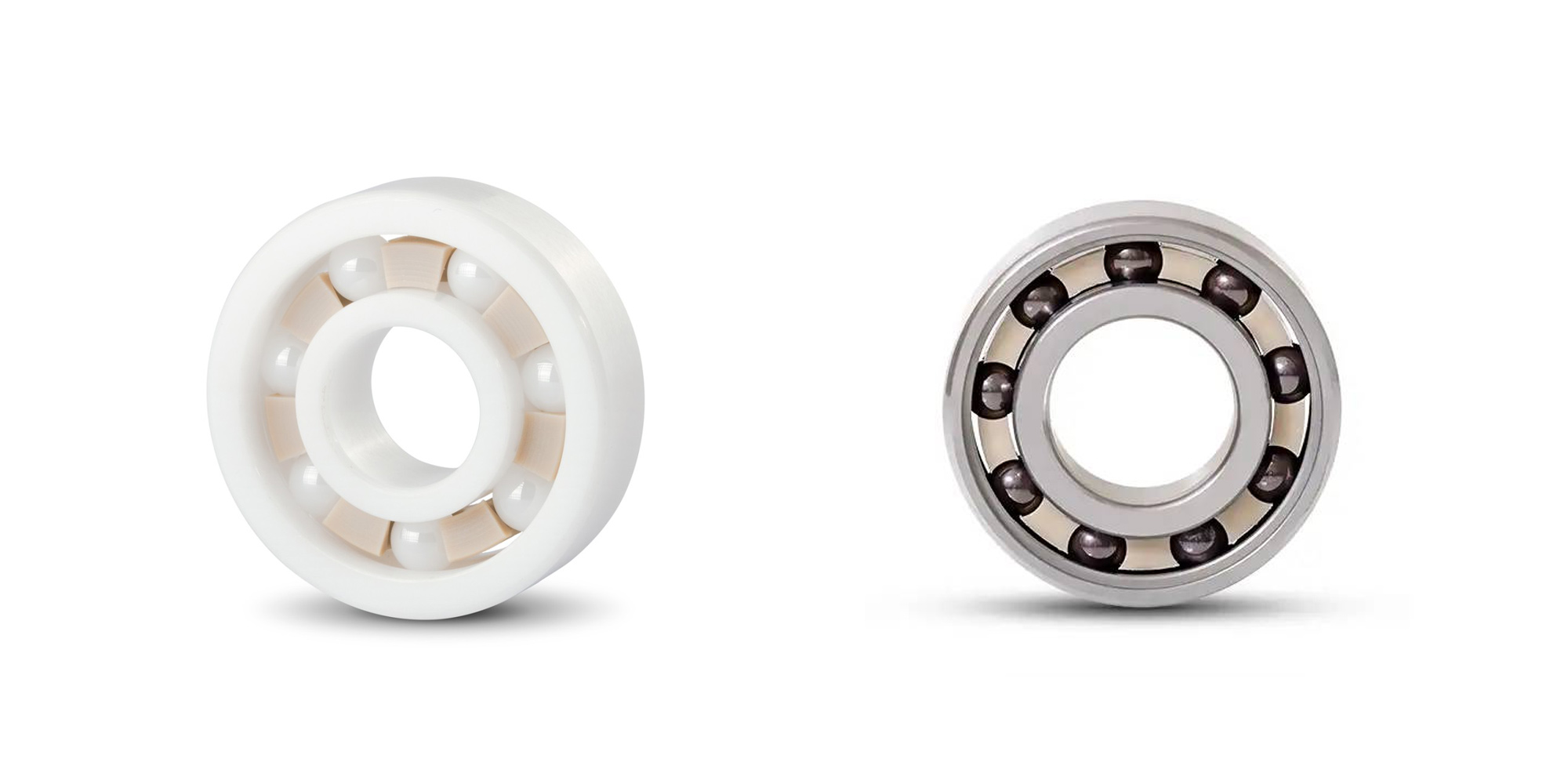

Uncoated bearings are made from metals like steel or bronze without any extra coating. They are preferred in situations where long-lasting performance and durability are needed.

Coated bearings have a layer of material like PTFE, ceramics, or polymers added to them. These bearings are used in places with extreme loads and short engine rebuild times.

About the two types of bearings, I will expand on performance comparison. Coated bearings outperform uncoated ones in several key areas:

Coated bearings cost more upfront but save money in the long run because they need less maintenance and last longer. They also keep machines running smoothly. Uncoated bearings are cheaper at first but can end up costing more over time due to frequent maintenance and replacements.

Uncoated bearings need regular lubrication to keep them running smoothly and prevent wear. They also need frequent checks to make sure they are in good shape. Because they wear out faster, they often need to be replaced more frequently. All this maintenance can lead to machine downtime, which can reduce productivity.

Coated bearings need less lubrication and fewer inspections because the coating makes them more durable. They last longer and reduce wear and tear. This means machines can run longer with less maintenance and fewer interruptions.

Uncoated Bearings:

Uncoated bearings are often used in household items like washing machines and fans. They are also used in electric motors and general industrial machines that work in mild conditions.

Coated bearings:

Coated bearings last a long time and need little maintenance. They are perfect for tough jobs like chemical processing equipment, where resisting corrosion is important.

Here's a table so you can get a clearer picture of them:

|

Criteria |

Coated Bearings |

Uncoated Bearings |

|

Friction Reduction |

Superior friction reduction due to specialized coatings. |

Standard friction levels, may require lubrication. |

|

Wear Resistance |

Enhanced wear resistance, longer lifespan. |

Lower wear resistance, more frequent replacements needed. |

|

Corrosion Resistance |

High corrosion resistance, suitable for harsh environments. |

Lower corrosion resistance, prone to rust and degradation. |

|

Temperature Tolerance |

Better tolerance to extreme temperatures. |

Standard temperature tolerance, may fail in extremes. |

|

Load Capacity |

Higher load capacity due to surface strength. |

Standard load capacity, may deform under high loads. |

|

Lifespan |

Longer lifespan, fewer replacements. |

Shorter lifespan, frequent replacements needed. |

Choosing the right bearing involves understanding various factors to ensure optimal performance and longevity. Here’s a simple guide to help you decide:

We offer custom solutions to fit your specific needs. Our coated bearings can be tailored to ensure optimal performance in your unique conditions.

Understanding Bad Cam Follower Symptoms The engine, often referred to as the heart of a vehicle, depends on several components to run smoothly. ...

Ceramic bearings are a type of bearing that uses ceramic materials either partially or fully. They are an alternative to traditional steel bearings....

High temperature bearings are made to withstand extreme heat and keep working reliably. They help machines run smoothly even in hot conditions. This...