Heavy Duty Roller Bearings: Key Advantages

Heavy duty roller bearings are designed to handle heavy loads in challenging conditions. Roller bearings are crucial in many industries that deal...

Cylindrical roller bearings are essential in industrial applications.They reduce friction and handle heavy radial loads. They also ensure the smooth operation of machines

This blog will explore the different types and key features of cylindrical roller bearings. The coverage will also include their applications. Additionally, it will provide tips on choosing and maintaining the right bearing for your needs.

Cylindrical roller bearings are mechanical components used in rotating machinery. They are designed to reduce friction and support radial loads. They use cylindrical rollers that provide a larger contact area than ball bearings. This design makes them better suited for handling heavy radial loads.

Here’s a comparison between cylindrical roller bearings and ball bearings in a table format:

|

Feature |

Cylindrical Roller Bearings |

Ball Bearings |

|

Load Capacity |

Greater load capacity because of larger contact area |

Lower load capacity compared to cylindrical roller bearings |

|

Rigidity |

Higher rigidity, ideal for heavy-duty applications |

Lower rigidity, better for lighter applications |

|

Axial Load Handling |

Suitable for high radial loads and moderate axial loads |

Handles small axial loads, less effective for high radial loads |

Inner Ring (Cone):

Outer Ring (Cup):

Role of Cylindrical Rollers:

Function of the Cage:

Cages in cylindrical roller bearings are important for keeping the rollers in place. They prevent the rollers from touching each other and ensure smooth operation. The material of the cage affects how well the bearing performs in different conditions. Here's a simplified look at the common types of cages:

Steel Cages

Brass Cages

Polyamide Resin (Nylon) Cages

Design Features:

Applications:

General Industrial Machinery:

Electric Motors:

Additional Radial Rigidity:

Cage-less Design:

Benefits in Heavy-Load and High-Stress Environments:

Key Features of Multi-Row Bearings:

Applications in Rolling Mills and Heavy Machinery:

Rolling Mills:

Other Industrial Machinery:

Multi-row bearings are used in other industrial machines like crushers, presses, and conveyors. These machines handle heavy, continuous loads. The extra capacity of multi-row bearings is crucial for reliable performance. They have a high load capacity and are durable. This makes them ideal for applications where bearing failure can lead to costly downtime.

The combination of full complement and cage designs in high-capacity cylindrical roller bearings gives extra load capacity. It also provides high-speed performance:

Applications:

Key Features:

Applications:

Key Features and Functions:

Applications:

Cylindrical roller bearings are great for handling heavy radial loads. This is because they have a larger contact area than ball bearings. This helps spread the load more evenly, allowing them to carry more weight without wearing out quickly.

The design also makes them stiffer, reducing stress and friction, which means they last longer. These bearings are ideal for tough industries like mining and construction, where heavy loads are common.

Cylindrical roller bearings have low friction because the rollers make line contact with the raceways. This helps them spin smoothly and quickly without creating too much heat. The reduced friction also reduce wear, making the bearings last longer and work better in high-speed situations.

Cylindrical roller bearings, especially full complement designs, are resistant to fatigue. Using more rollers helps spread the load evenly, reducing stress and wear. This makes them last longer, even under heavy use, and makes them perfect for tough, long-lasting performance.

Cylindrical roller bearings can be customized for different industries by adjusting the internal clearance and lubrication. The internal clearance is the small gap between the rollers and raceways. It can be made tighter for precise applications or larger for high-temperature environments.

Lubrication can also be customized. The right type of oil or grease helps reduce friction and keeps the bearing running smoothly. This customization helps ensure the bearings work well in different conditions, like in cars, airplanes, and heavy machinery. It makes them last longer and perform better.

Cylindrical roller bearings are used in wind turbine gearboxes to support heavy radial loads. They work reliably in tough environments, ensuring smooth operation. Their durability lasts even in extreme conditions like high wind speeds and changing loads.

Cylindrical roller bearings are used in mining equipment and crushers to handle heavy loads. They provide stability and support under intense pressure, helping machines like crushers and mills run smoothly. These bearings can withstand shocks and vibrations in tough environments, making the equipment more reliable and longer-lasting. They help distribute the load evenly, reducing damage and the need for maintenance.

Selecting the right bearing is crucial for ensuring smooth operation and extending the life of machinery. Here's a guide based on different load types:

Importance of Matching Bearings to Load Requirements:

When choosing bearings for specific applications, speed and rigidity are two key factors to consider:

Speed Requirements:

Rigidity Requirements:

Here are some tips for selecting cylindrical roller bearings for applications with extreme temperatures, humidity, or dirty environments:

Regularly inspect bearings for wear, misalignment, and lubrication. This helps ensure they perform at their best and last longer.

Using the right lubricant is key to how well a bearing works and how long it lasts. Grease is ideal for low-speed components. It effectively prevents dirt ingress and maintains its position for a longer duration.

Oil is better for fast or hot-running parts because it cools the bearing and reduces friction. Choosing the right lubricant helps the bearing work smoothly, reduces wear, and prevents overheating, making it last longer.

Cylindrical roller bearings are strong and can handle heavy loads. They reduce friction, helping machines run smoothly and last longer. They are reliable and need less maintenance, making them ideal for heavy-duty machines.

When choosing a cylindrical roller bearing, it's important to consider your specific needs. Think about the load, speed, and environmental conditions of your application. This will help you pick the right bearing to ensure smooth operation, longer service life, and optimal performance.

If you need help choosing the right bearing, feel free to contact LILY Bearing. We also offer custom solutions tailored to your specific needs. Our experts are ready to guide you in selecting the best bearings for your application.

Heavy duty roller bearings are designed to handle heavy loads in challenging conditions. Roller bearings are crucial in many industries that deal...

Roller bearings are vital components in modern machinery. They play a critical role in ensuring smooth, efficient, and reliable operation across a...

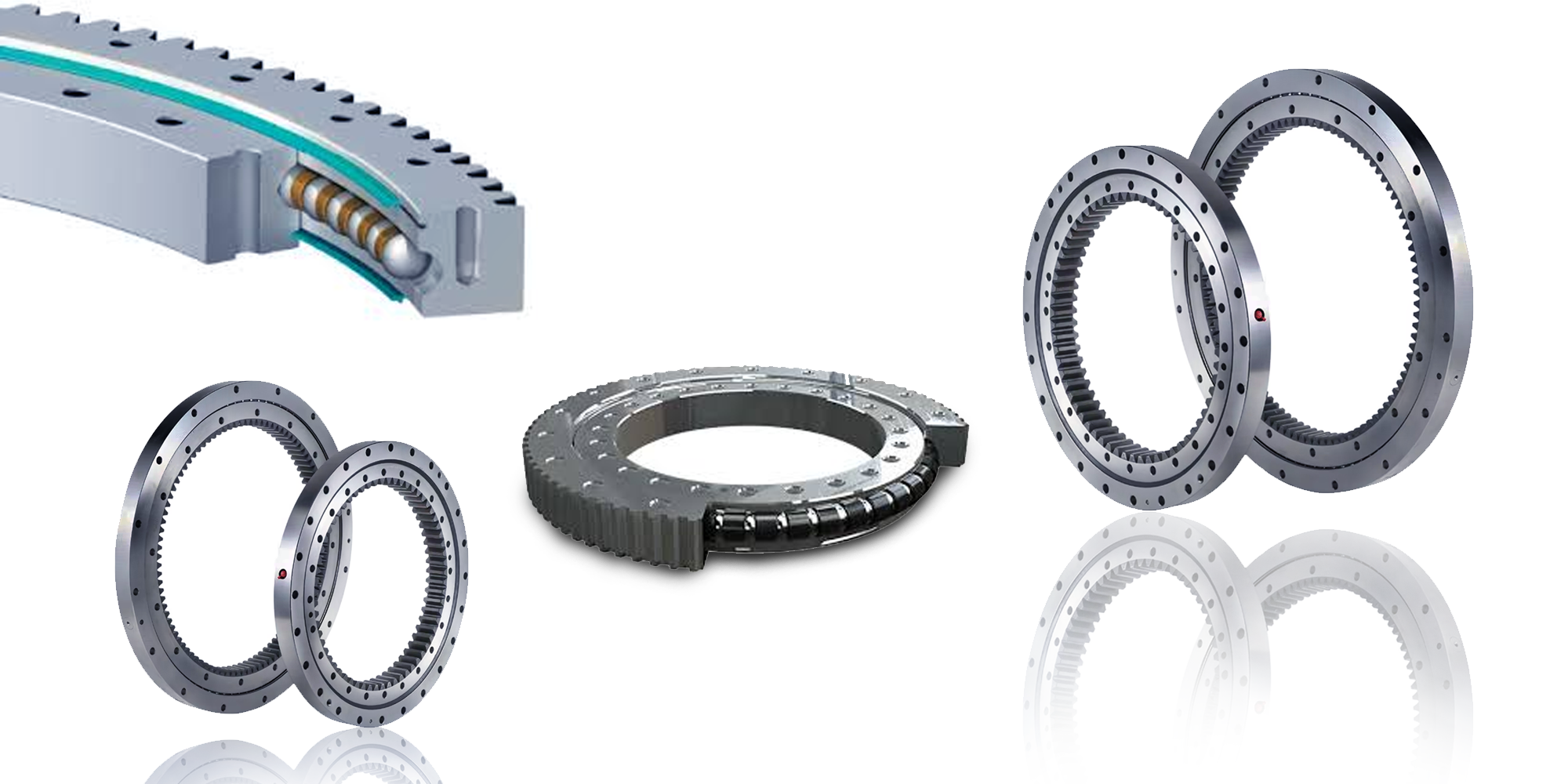

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...