Best Grease for High Temperature Bearings

Hightemperature bearings are important in industries like automotive, steel production, and energy. They can handle extreme heat and still work well.

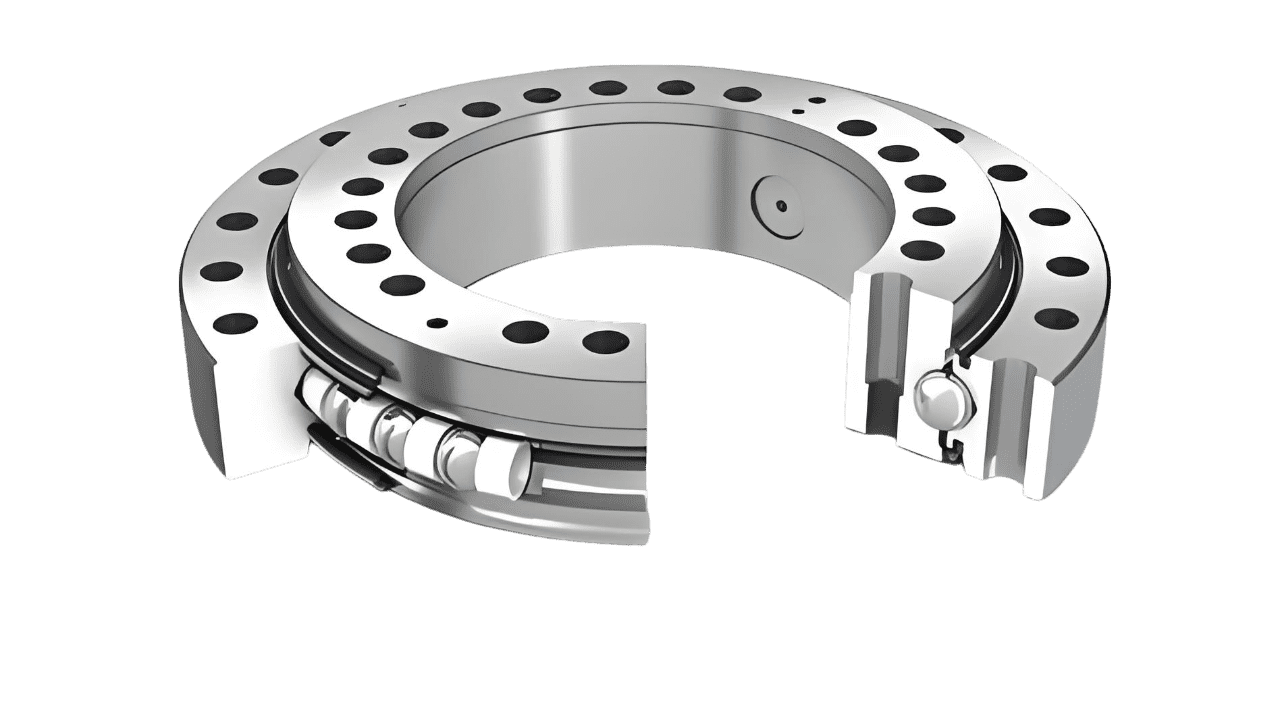

Coated bearings are standard bearings. They have a layer of special material on them that makes their surface better. This treatment helps them work better and last longer. Over time, coated bearings have become important in many industries because they perform so well.

Traditional bearings can wear out quickly and rust easily, which shortens their lifespan. New coating technologies have fixed these problems. These coatings make bearings stronger and more reliable, especially in tough conditions.

In this blog, we will highlight the benefits of coated bearings with specific examples and applications.

Coated bearings are special parts that make traditional bearings work better and last longer. They reduce friction between moving parts, help carry loads, and ensure smooth motion. This makes them important in many industries that need reliable equipment.

Different types of coatings are used on these bearings, such as urethane, ceramic, and Teflon (PTFE). These coatings help the bearings perform better in tough conditions and increase their lifespan.

Coated bearings offer many advantages over traditional bearings, such as:

Coated bearings have low friction coefficients. This lowers the energy needed to move, making operations smoother and more efficient.

Lower friction also means less heat generation. This can improve the overall efficiency of machinery.

Coatings help the bearings get rid of heat better, preventing them from overheating. This keeps the bearings working well even in tough conditions.

Coatings are added to bearings based on the material of the bearing's surface. Different coatings work best with specific materials, helping them bond well and perform better. Urethane coated bearings have special advantages that are useful in some industries. They are strong, flexible, and resistant to various environmental factors. This makes them ideal for uses where other bearings might not work as well.

Here are the main benefits of urethane-coated bearings and the industries that benefit the most from them:

Choosing the right coated bearings for a specific job needs careful thought about several factors. This ensures optimal performance under given conditions. Here are some key factors to consider:

Choosing the right coating for bearings depends on the job's needs. Selecting the appropriate coating ensures optimal performance.

Here’s a comparison of common coatings: urethane, ceramic, and Teflon (PTFE). Each has unique benefits for specific uses. Choose based on your needs.

Coated Bearings are more resistant to lack of lubrication when it comes to wear and damage on the bearings. Nonetheless, this does not mean that the need for maintenance is eliminated. Here are some measures you can take:

Establish a Routine Inspection Schedule: Set up a regular inspection schedule based on manufacturer recommendations. High-load and high-speed uses need more frequent checks.

Check the condition of the lubricant for contamination, discoloration, or depletion. Clean and replenish or replace the lubricant as needed to ensure proper lubrication.

Clean and store coated bearings properly to make them last longer and work well. If you need to take them apart for cleaning, follow the manufacturer's guidelines carefully to avoid damage.

In this passage, we have talked about the benefits of coated bearings and the different types of coatings, especially urethane coated bearings. These bearings improve the performance, reliability, and lifespan of machines and equipment. Explore coated bearings for your needs with LILY Bearing. Contact us for further inquiries.

Hightemperature bearings are important in industries like automotive, steel production, and energy. They can handle extreme heat and still work well.

In the intricate realm of aerospace, ball bearings serve a pivotal role, ensuring precision, efficiency, and durability in various mechanical...

Bearings are mechanical parts that support and guide rotating or moving components, like shafts or wheels, while minimizing friction. Sleeve Bearings...