8 Common Uses for Polyurethane Coated Bearings

Polyurethane coated bearings, sometimes called polyurethane rollers, show off modern engineering at its best. They stand out for exceptional...

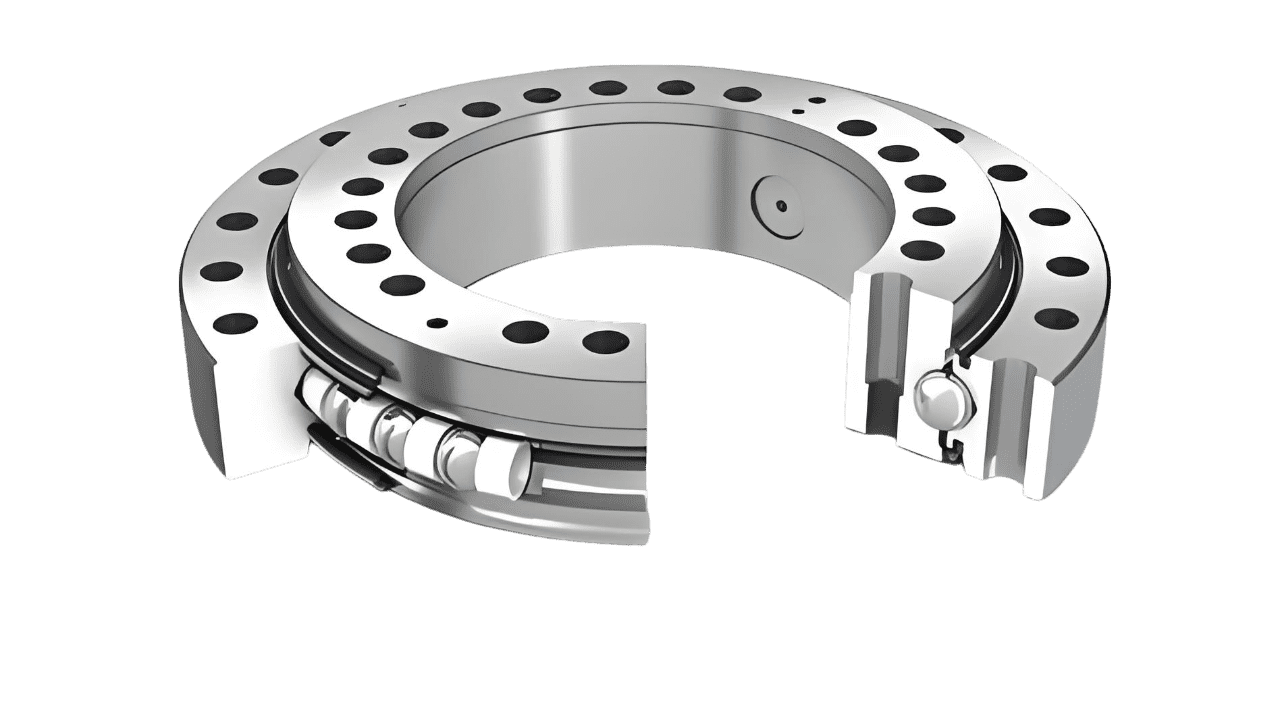

To improve their performance and service life, coatings are applied to these bearings, creating what we know as coated bearings. This blog explores the types, benefits, operating conditions of coated bearings, and why polyurethane coated bearings, specifically, stand out for their exceptional characteristics and high performance. In the realm of machinery and mechanical systems, the reliability and efficiency of components are vital. Bearings are especially critical for reducing friction and wear in rotating parts.

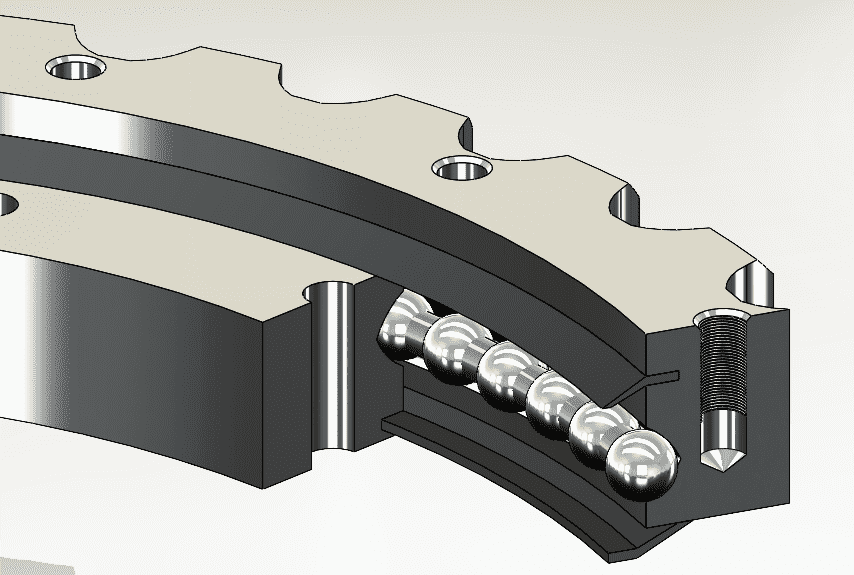

Coated bearings are engineered with an additional layer applied to their surfaces, which enhances their inherent properties. The general purpose of these coatings is to reduce friction, prevent wear, and extend the life of the bearings. The overall benefits of using coated bearings include improved performance, reduced maintenance, and a smaller environmental footprint.

Coated bearings come in all sorts of varieties, and each one has its own special benefits that make it perfect for certain uses.

Polymer coatings on bearings make them more resistant to abrasion and shock loads help them slide more smoothly. They act like a protective layer, helping the bearings last longer. This is especially useful in rough conditions filled with dirt and grime.

Ceramic coated bearings are great at dealing with heat, so they have a long life. They stay tough even under extreme heat, making them perfect for fast-spinning machines or parts deep inside engines. These bearings don't let you down where traditional metal ones, such as high-speed machinery and engine bearings might.

Teflon(PTFE) coated bearings offer an impressively low coefficient of friction and chemical resistance. They are ideal for applications where non-stick properties and resistance to corrosive substances are required.

Coatings made of polymer on bearings enhance their wear resistance and lower friction. This protective layer greatly extends these bearings' life, especially in tough conditions with a lot of contamination.

Dry film lubricant coatings work great in tough and high-demand settings. They create a smooth, long-lasting layer that makes things slide against each other with less friction and wear. This is different from usual liquid lubricants, which might evaporate or lose their effectiveness in really tough conditions.

The coatings applied to bearings help to decrease friction between bearing surfaces. This reduction in friction results in smoother operation, reducing energy consumption and extending the service life of the bearings.

The coatings applied to bearings help to decrease friction between bearing surfaces. This reduction in friction results in smoother operation, reducing energy consumption and extending the service life of the bearings.

During cold starts, when lubrication is low, coated bearings add extra protection to prevent too much wear. This benefit is vital in cars and industrial equipment that often start from a standstill.

Coated bearings keep working well under intense pressure, high speeds, and extreme heat. Their coatings shield the bearing surfaces, making sure they operate smoothly even in the toughest situations.

Coatings shield bearings from rust, making them a great choice for places with moisture and harsh chemicals. This helps bearings last longer and stay reliable even in tough conditions. The protective layers keep bearings safe from moisture and harmful substances, ensuring they last longer.

Coated bearings can support heavier weights because they spread stress evenly across their surfaces. This feature is especially useful in heavy machinery and situations needing high load support. The coating helps manage heavier loads smoothly by spreading stress evenly.

Coated bearings hold onto lubrication better, which means less need for re-lubrication and better performance overall. This is especially important in situations where regular maintenance is hard or rare.

Coated bearings are built to be tough, which means people won't need to check on them as often and replace them less frequently. This results in lower costs and less time when your equipment is sitting idle waiting for repairs.

Coated bearings are a popular choice in many industries because of their improved qualities. Common applications for these bearings include:

Polyurethane-coated bearings are great for places that need things to be highly wear-resistant and flexible. They're chosen for their ability to last a long time and handle heavy loads, which is especially important in these settings.

Polyurethane coated bearings are made with great care. Here's how it's done:

Polyurethane coated bearings offer many advantages. They are resistant to rust, can take on big loads, and are really durable against wear and tear. They are engineered to endure tough conditions, ensuring dependable operation and cut-down need for frequent maintenance.

Let's take a look at how polyurethane-coated bearings shine in different real-life scenarios:

Calico Coated Bearings

Calico coated bearings, a collaboration with ACL and Mahle/Clevite, feature cutting-edge CT-1 or CT-11 Dry Film Lubricant coatings. These special coatings cut down on friction, stand up to wear and tear, and keep dirt at bay. Besides, they boost the bearings' toughness, strength, and longevity, making them just right for high-performance motorsports.

Calico coated bearings are perfect for high-performance tasks. They reduce friction, so things run more smoothly and don't heat up as much. Plus, they help parts last longer. Their enhanced durability and abrasion resistance make them last longer, even in tough, motorsport conditions. Besides, they shrug off dust and dirt, ensuring consistent performance. The coatings' embeddability and added strength are favored by professionals and can be customized with CT-11 for specific requirements.

Calico Coated Bearings are favorites for their top-notch performance and toughness.

Calico Coated Bearings are ideal for all sorts of challenging tasks. Whether it's racing, big engines in airplanes or boats, factory machinery, green energy projects, off-roading, or any tough vehicle use, these bearings excel. They're great at reducing friction and wear, preventing rust even in harsh conditions, and ensuring smooth operation no matter how challenging the situation.

Picking the perfect coated bearings is all about matching them to your needs. Think about where and how you'll use them, what kind of load required to carry, and the environmental conditions they'll be in. Taking the time to get a clear picture of these details will help you find bearings that work just right for your setup.

| Coating Type | Best Use Cases | Key Features |

| DLC Coated Bearings | High-load, high-speed environments | Low friction, high hardness, wear resistance |

| PTFE Coated Bearings | Non-stick surfaces, food processing | Chemical resistance, non-stick |

| Nitrided Bearings | General industrial, fatigue and corrosion | Improved hardness, wear resistance |

| Phosphate Coated | Marine environments, corrosion resistance | Provides base for paint, enhanced corrosion resistance |

| Zinc/Nickel Plated | Corrosion protection, decorative finish | Good corrosion resistance, decorative |

| Si3N4 Coated Bearings | High-temperature applications | Thermal stability, low thermal expansion |

| MoS2 Coated Bearings | Dry lubrication, outdoor machinery | Solid lubrication, good for low-speed, high-load |

| Tungsten Carbide | Heavy-duty, abrasive environments | Extreme wear resistant |

Maintaining coated bearings is key to keeping them running smoothly for longer. Here's a simple tips on regular maintenance:

Common issues like wear, getting dirty, or not having the right lube can shorten a bearing's life. To avoid this:

Getting the right coated bearings is key to making your machinery last and perform well with lower upkeep cost. This article has covered a range of coated bearings, especially polyurethane-coated ones.

If you're in the market for bearings, think about going with polyurethane-coated ones. They're worth checking out for the advantages they bring to your work.

For smooth and reliable performance, get in touch with LILY Bearing. They offer expert guidance to help you find the best solution and the ideal fit for your specific requirements.

Polyurethane coated bearings, sometimes called polyurethane rollers, show off modern engineering at its best. They stand out for exceptional...

Understanding Bearings Bearings are important parts in machines that help things move smoothly. They reduce friction, which makes them easier for...

Coated bearings are standard bearings. They have a layer of special material on them that makes their surface better. This treatment helps them work...