Radial vs. Axial Load: Understanding the Differences

Radial and axial loads apply force in different directions, and using the wrong bearing type can lead to premature wear, system inefficiencies, or...

3 min read

Goodenough Lu

:

Aug 21, 2025 10:17:55 PM

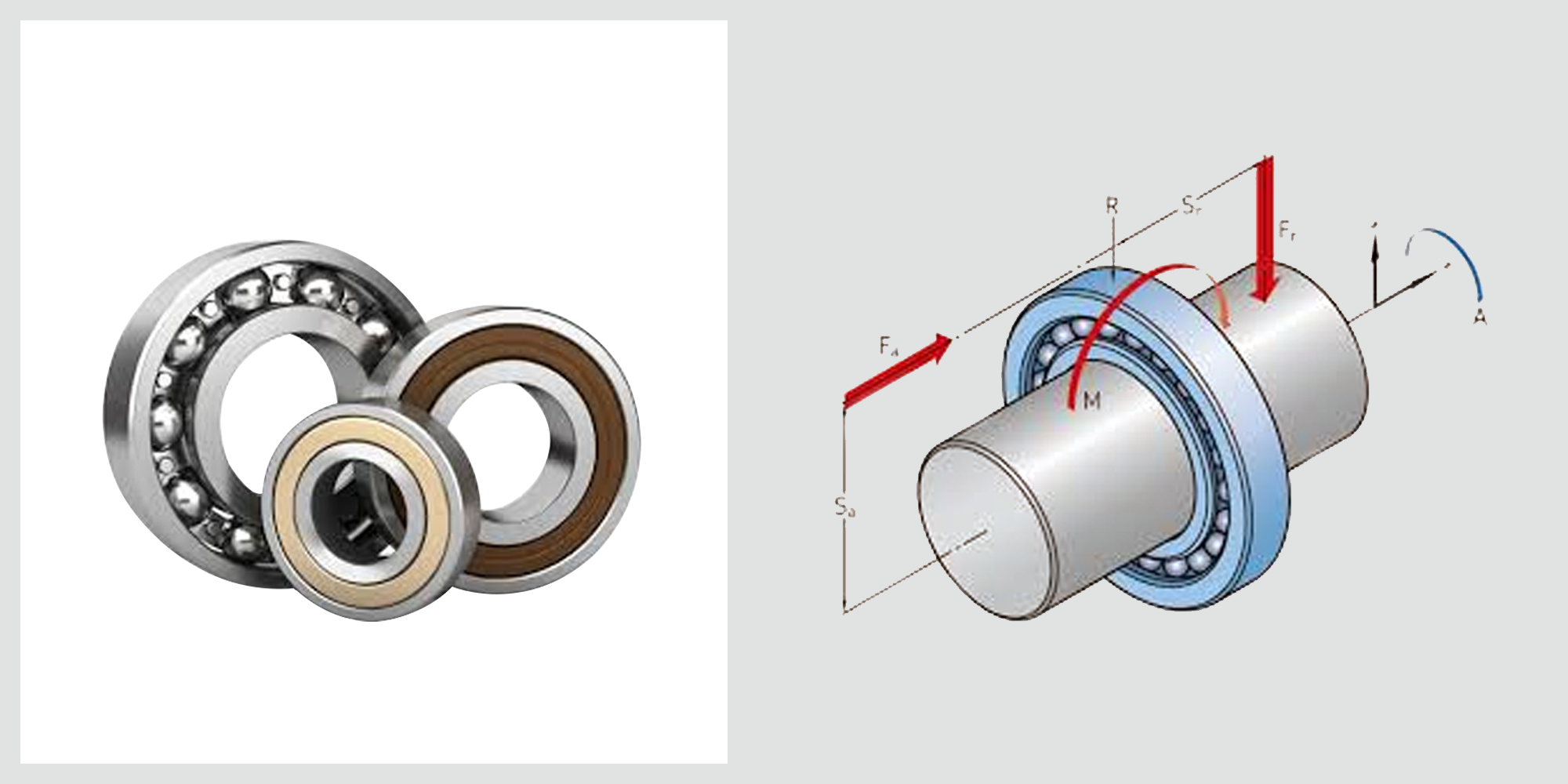

Bearings play a vital role in machinery by ensuring smooth motion and reducing friction.

Understanding load capacities, specifically static load vs dynamic load, is essential for optimal bearing performance.

This blog will explain these load types and their importance in selecting the right bearing for your applications and custom bearing solutions, helping ensure reliable and efficient operations.

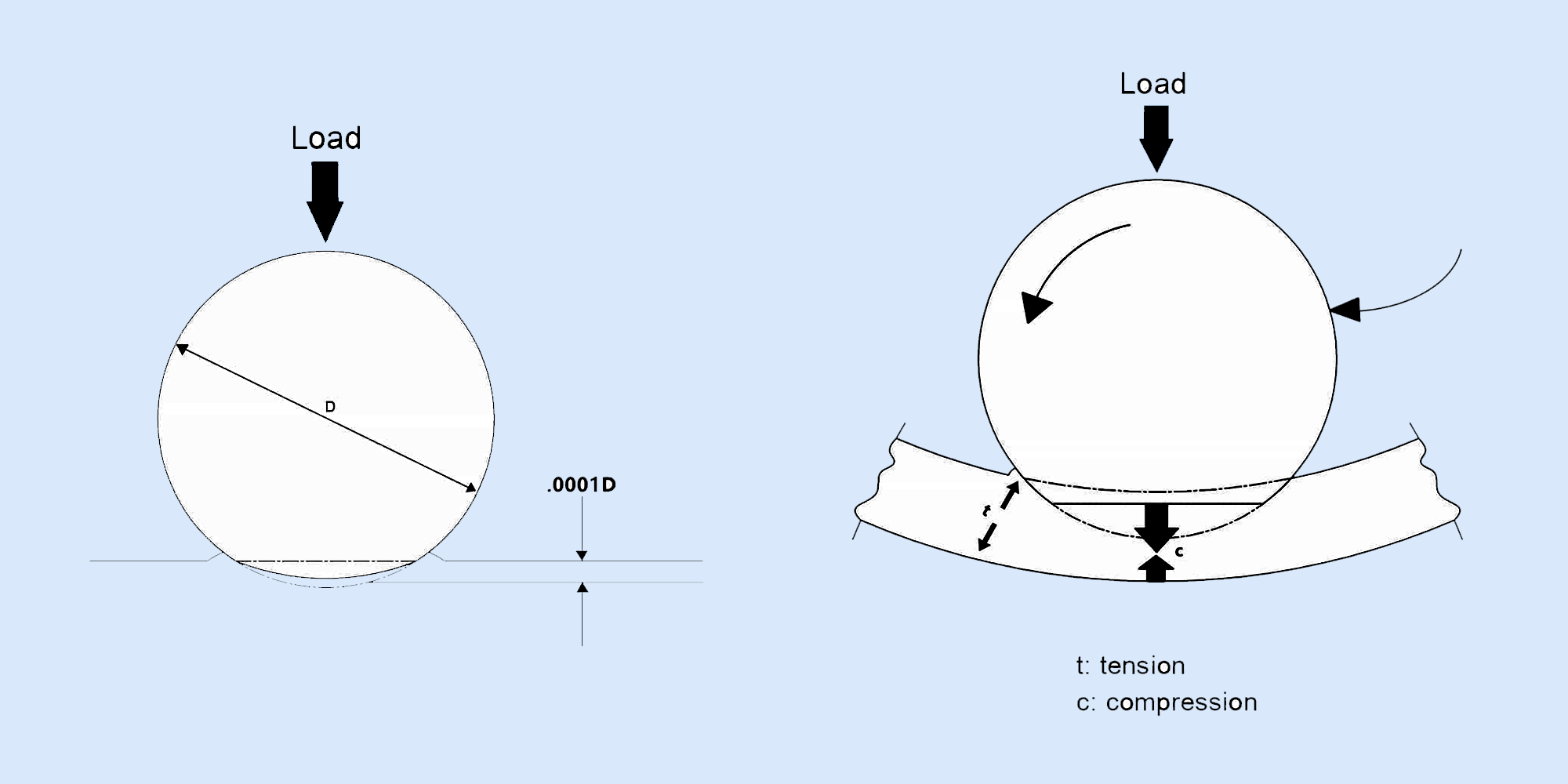

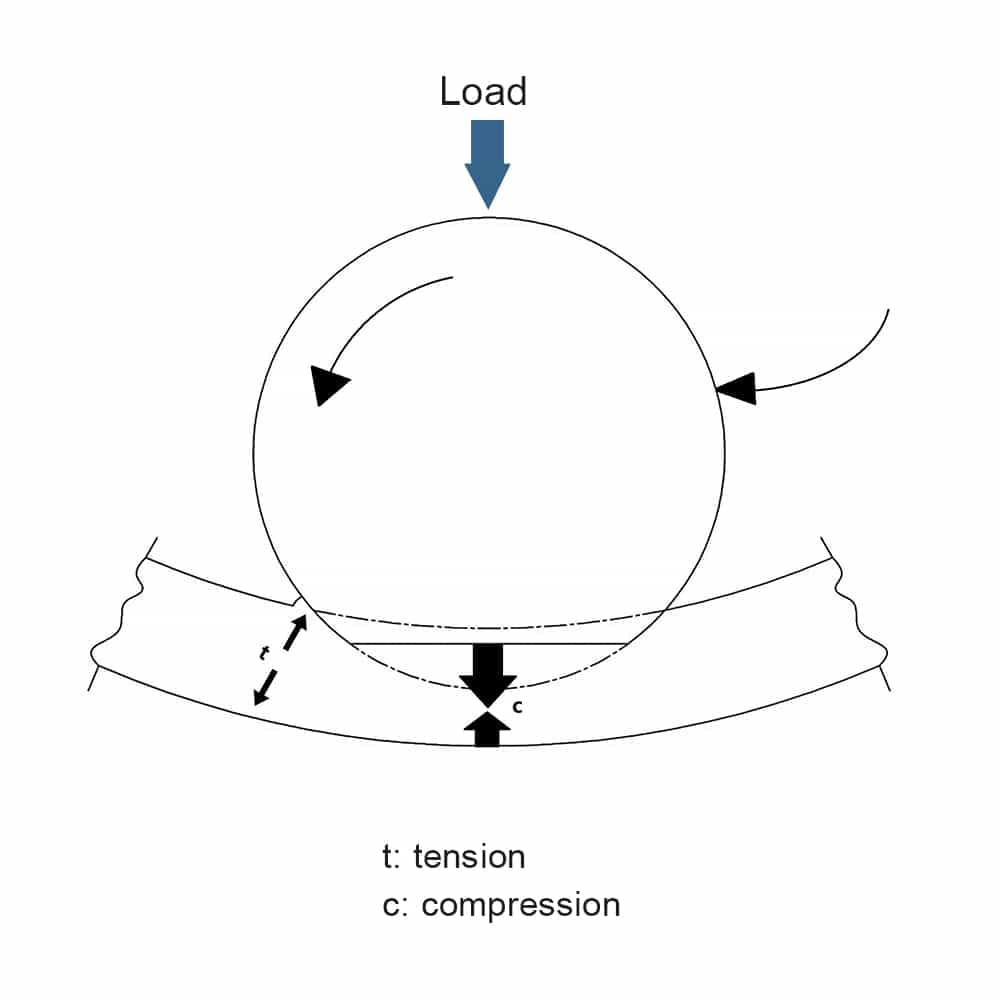

Static load refers to the load exerted on a bearing when it is stationary or under slow movement.

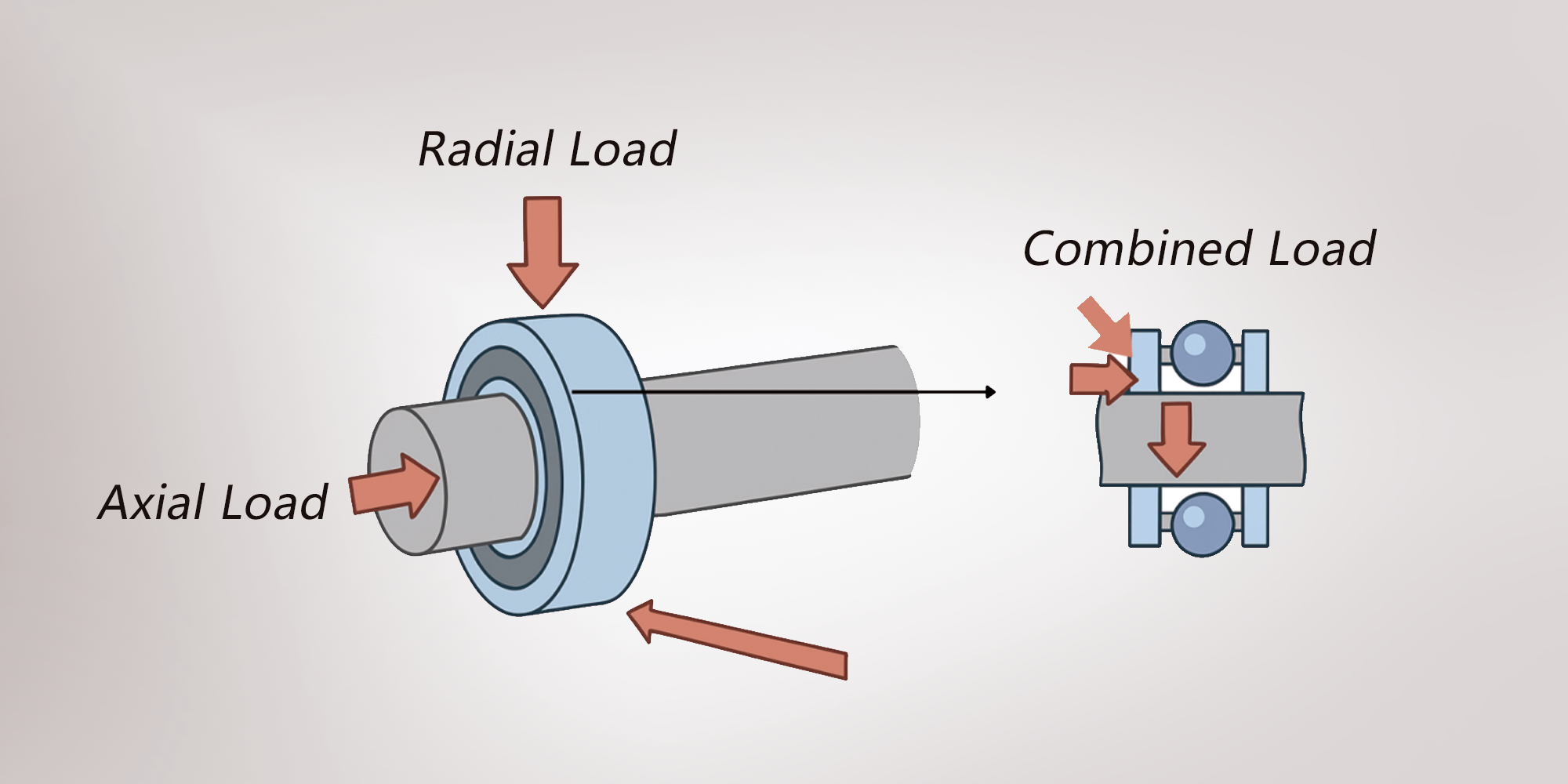

Dynamic load refers to the load that a bearing supports during continuous movement, including both radial and axial loads.

Understanding static and dynamic load capacities ensures the longevity and reliability of bearings.

Properly selected bearings can handle the expected loads without failure, reducing maintenance costs and downtime.

This knowledge is vital for engineers and technicians in designing and maintaining efficient machinery.

Nature of Load:

Capacity Measurement:

Impact on Bearing Life:

Rolling element linear bearings include round shafts, bushings, profiled rail guides, crossed roller slides, and ball screws.

They have two main load capacity specifications: dynamic load capacity and static load capacity.

Understanding these specifications is crucial for accurately sizing and selecting bearings.

Static loads often arise from unexpected shocks that are challenging to measure.

To address this, manufacturers of linear bearings and ball screws recommend using a static safety factor.

This factor is the ratio between the basic static load rating and the maximum combined static load.

It varies based on the application and operating conditions.

For environments with low vibration risk, a factor of 2 is suggested.

For conditions with potential severe shocks, factors of 5 or 6 are advised to ensure reliability and prevent damage.

S0 =C0/F0max

Where:

S0: the static load safety factor

C0: the static load capacity

F0max: the maximum combined static load

Dynamic load capacity (C) is a crucial parameter for determining the lifespan and reliability of rolling element linear bearings under continuous motion.

This capacity is derived through empirical testing, where a bearing is subjected to a constant load magnitude and direction.

The bearing must reach a specific travel distance or number of revolutions without showing fatigue.

Fatigue appears as flaking on the rolling elements or raceways.

For linear bearings using balls:

L10=(C/F)3×100,000

For linear bearings that use rollers:

L10=(C/F)10/3×100,000

Where:

L10: calculated (rated) life of the bearing in meters

C: basic dynamic load capacity (N)

F: applied load (N)

Conversion for Travel Distance:

If comparing bearings rated for different travel distances, use the following conversion:

LILY Bearing offers a wide selection of high-quality industrial bearings suitable for various applications.

Our expert team can help you choose the right bearings based on static and dynamic load capacities, ensuring optimal performance and longevity for your machinery.

Visit our website to explore our range of products and find the perfect bearing solution for your needs.

Understanding static load vs dynamic load in bearings is essential for choosing the right bearing for your needs.

Get your bearings at LILY Bearing, LILY Bearing offers a wide selection of high-quality industrial bearings suitable for various applications.

Our expert team can help you choose the right bearings based on static and dynamic load capacities, ensuring optimal performance and longevity for your machinery.

Visit our website to explore our range of products and find the perfect bearing solution for your needs.

Radial and axial loads apply force in different directions, and using the wrong bearing type can lead to premature wear, system inefficiencies, or...

Understanding bearing axial load, just like understanding different types of bearing load, is crucial for ensuring the proper functioning and...

Bearings may be small components, but they have a big job. That includes everything from supporting loads in rotating shafts to absorbing axial...