How to Prevent Bearing Failures: Tips and Techniques to Reduce Wear on Bearings

Bearing failures can be a major headache for any facility, causing increased downtime, high-maintenance costs, missed deliveries, loss of revenue...

Needle bearings play a crucial role in applications where space, load capacity, and reduced friction are essential.

Proper installation is critical for ensuring that needle bearings function as intended.

The objective of this blog is to provide practical tips for successfully installing needle bearings.

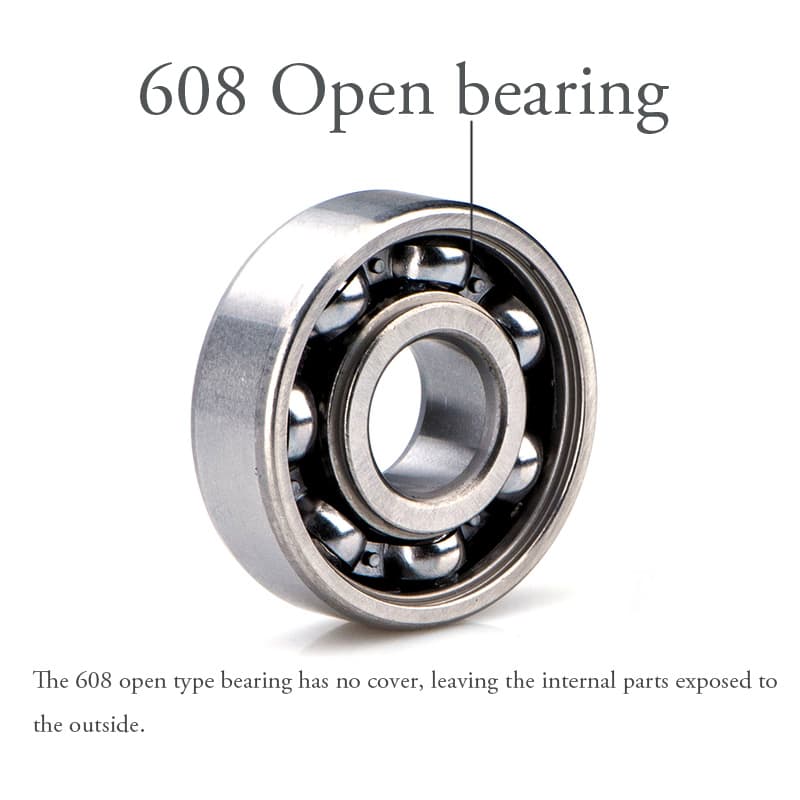

Needle bearings are a type of rolling-element bearing.

They use cylindrical rollers with a high length-to-diameter ratio. These rollers, known as "needles," are much longer and thinner than traditional cylindrical rollers.

Needle bearings reduce friction by using long, thin rollers that roll smoothly along their raceways, rather than sliding.

This rolling motion creates less resistance compared to traditional sliding bearings.

Their design allows them to carry heavy loads despite their small size.

Here are the essential tools required for properly installing needle bearings:

Before installing needle bearings, it's important to verify that all tools and equipment are clean and ready to use.

Check the needle bearing for any signs of damage, deformation, or pollution before installing needle bearings.

Ensure the housing or shaft surface is clean, free from debris, and within the recommended tolerance levels.

Proper alignment of the needle bearing during installation is crucial to avoid damage and ensure smooth operation.

Misalignment can cause uneven wear, increased friction, and even bearing failure.

By aligning the bearing correctly with the shaft and housing, you help it function efficiently and extend its lifespan.

Lubrication plays a key role in the performance and longevity of needle bearings.

It reduces friction between the rollers and raceways, preventing excessive heat buildup and wear.

Proper lubrication also helps protect the bearing from contaminants, reducing the risk of corrosion and damage.

|

Lubricant |

Grease |

Oil |

|

Composition |

Thickened oil (semi-solid) |

Liquid lubricant |

|

Advantages |

- Stays in place longer |

- Excellent cooling properties |

|

Disadvantages |

- Less effective at cooling |

- Can leak or evaporate if not sealed properly |

|

Best For |

- Lower-speed applications |

- High-speed applications |

|

Environment |

- Better for preventing pollution |

- Better for cooling in high-temperature environments |

When installing needle bearings, it's highly recommended to use a bearing press or driver tool.

These tools apply steady, even pressure to the bearing during installation, ensuring it is seated correctly without causing damage.

Using a bearing press or driver helps avoid misalignment, distortion, or damage to the bearing race.

These issues can occur if pressure is applied unevenly or too forcefully by hand.

This method ensures a smooth and precise installation, prolonging the bearing's lifespan and ensuring optimal performance.

Avoid hammering the bearing into place when installing needle bearings. Using a hammer can cause uneven pressure, leading to damage of both the bearing and the housing.

Be careful not to apply too much force when installing needle bearings.

Excessive pressure can damage the bearing or its rollers, leading to problems like increased friction and early failure.

Always use the right tools to press the bearing in gently and evenly for a smooth installation.

Make sure the bearing is fully seated during installation, but avoid using excessive force.

Gently press it into place to ensure it fits securely without damaging the bearing or surrounding components.

Check the fit of the needle bearing after installation to ensure it is correctly seated.

Measure the bearing and housing to confirm that the bearing is properly aligned and fitted within the specified tolerances.

Manually rotate the bearing after installation to ensure it moves smoothly without obstruction.

Check for any unusual sounds or resistance that could indicate improper installation.

Ensure that the bearing can handle the intended load without any issues.

Inspect for signs of wear or damage under load conditions during testing.

Regular inspection and maintenance are important for keeping needle bearings in good condition.

Check the lubrication, make sure the bearing is properly aligned, and look for signs of wear.

Address any issues early to help the bearing last longer and work smoothly.

Recommend replacing the bearing if any damage or signs of failure are detected.

Improper alignment is a common cause of needle bearing failure.

When the bearing isn't aligned correctly, it causes uneven pressure, leading to wear and friction. (Here is How to Prevent Bearing Failures)

This can make the bearing fail early, so proper alignment is important for longer-lasting performance.

Don't use incorrect or makeshift tools when installing needle bearings.

Using the wrong tools can damage the bearing and housing, causing misalignment or deformation.

Always use the right press and driver tools to ensure a safe and proper installation.

A bearing press or bearing driver ensures even pressure, preventing damage to the bearing or housing.

These tools help seat the bearing correctly and maintain proper alignment.

Using the right tools minimizes the risk of errors. This extends the bearing’s lifespan and ensures smooth and reliable operation.

Lubricating the bearing before and during installation is crucial for proper needle bearing setup.

Lubrication helps reduce friction, making the installation process smoother and preventing damage to the bearing and housing.

It also ensures the bearing operates efficiently from the start and helps protect it from wear and corrosion.

Without enough lubrication, friction increases, which makes the bearing get too hot and wear out faster.

This can cause premature failure, and the bearing might stop working properly.

Proper lubrication helps the bearing run smoothly, stay cool, and last longer.

Forcing the bearing into place can cause permanent damage to both the bearing and the machine.

Applying too much pressure can deform the bearing, misalign it, or damage the housing.

Always use the correct installation tools. Apply steady, even pressure to avoid issues and ensure a proper fit.

Following best practices is essential when installing needle bearings. Always refer to the manufacturer's guidelines for specific instructions related to your equipment.

If you have any needs, please contact LILY Bearing.

Bearing failures can be a major headache for any facility, causing increased downtime, high-maintenance costs, missed deliveries, loss of revenue...

Kaydon is known for leading the bearing technology. Kayddon bearings offer creative ways to ensure longer service life of bearings. They are great at...

Bearings play a critical role in the health of industrial machinery, ensuring operations run without a hitch. The processes of 'how to install a...