Characteristics, Uses and Advantages of Stainless Steel Bearings

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...

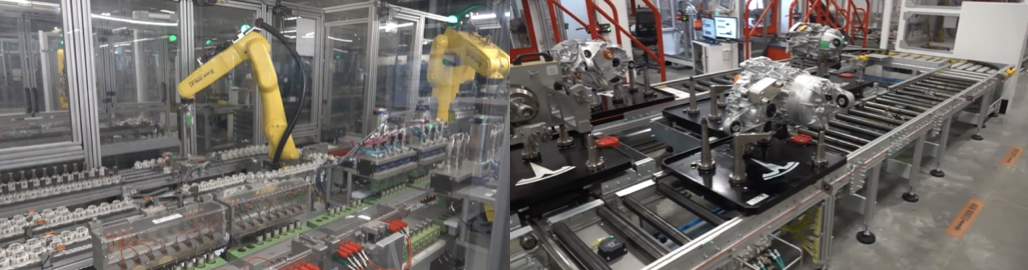

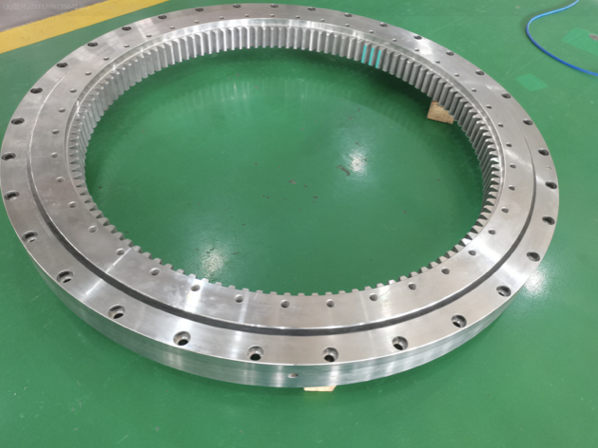

LILY has supplied assistance in Tesla’s create new products at the Gigafactory, a special custom slewing bearing made by Lily Bearing will soon start working in Tesla’s Gigafactory.

In May of 2021, Tesla found LILY BEARING and want us to customize a slewing bearing for Tesla’s Gigafactory in sparks.

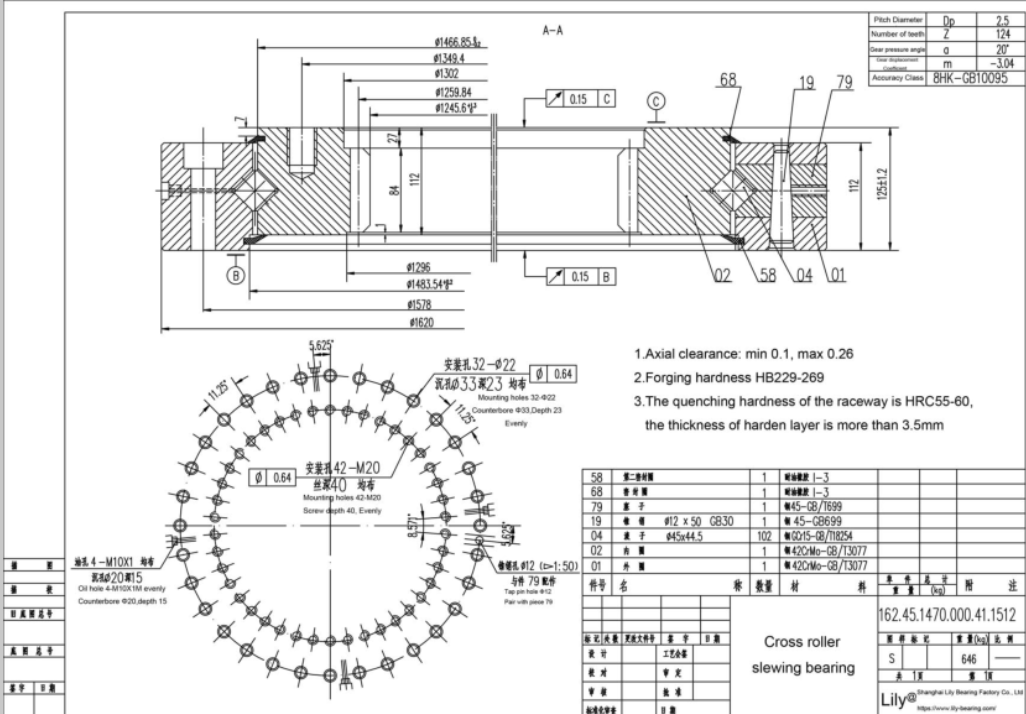

After communicated with Tesla’s technical team several times, Lily’s technical team carried out a special structural design for their project on the basis of model RK6-16. With using the special material and processes, the slewing bearing’s rotary accuracy and life time have been ensured. At the same time, the inside structure lightest design make sure the harsh loads. Based on the professional solution, Tesla final decide to proceed this order with LILY BEARING.

Non-stand custom slewing bearing

And it turns out that Tesla’s trust is worthy, the slewing bearing has been delivered to Tesla on October 2021, which has been highly recognized by Tesla and the product has passed the smooth acceptance.

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...

In the demanding realm of food processing and packaging, every component's efficiency and reliability are critical for operational success and health...

Industry Potential of Antennas and Telescopes During the transition from 4G to 5G, antenna technology has been continuously advancing, including...