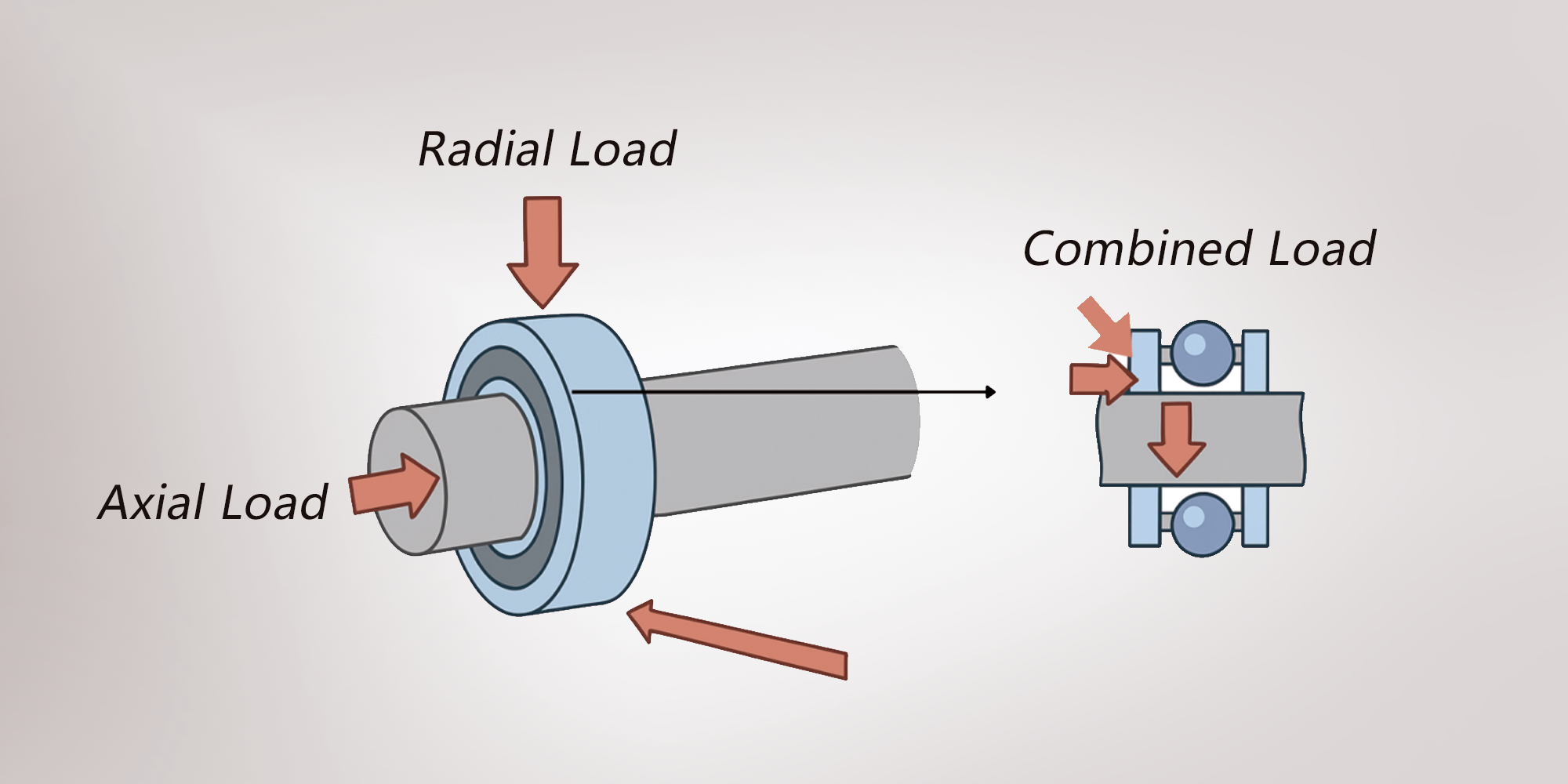

Radial vs. Axial Load: Understanding the Differences

Radial and axial loads apply force in different directions, and using the wrong bearing type can lead to premature wear, system inefficiencies, or...

Acting as the key "hinges" in large machines like cranes and excavators, slewing ring bearings enabled them to rotate smoothly and with precision in a wide range of applications. These bearings, also called slewing ring turntable bearings, can manage different loads, including thrust, radial, and tilting moment loads.

Keeping these bearings in good condition is essential for their long life and top performance. Without routine maintenance for them, they might cause your machines to stop working, need expensive fixes, or even be unsafe when you're using heavy machinery.

To keep running smoothly, slew bearings need the right kind of grease. The choice depends on how and where the machine is used.

There's lithium complex grease for everyday jobs, polyurea for hot and heavy work, aluminum complex for wet places, and synthetic greases for very hot or cold conditions. EP greases give extra protection under heavy loads, and food-grade greases are perfect for the food industry. For cold places, there's special low-temperature grease.

Following the maker's advice on using grease is key to keeping the turntable bearing lasting long periods, especially for custom slewing rings.

A good rule of thumb for lubrication is to do it every 100 hours of operation. But if the machine runs at high speed or works in tough conditions, it might need more frequent lubrication. Always check what the machine's maker suggests for best results.

Proper lubrication of a slew bearing is crucial for its longevity and high performance. Here is a step-by-step guide on how to add grease to bearings correctly:

Preparation:

Grease Selection:

Grease Application:

Lubrication Points:

Rotation: Rotate the bearing while applying grease to help distribute it evenly within the bearing.

Grease Quantity:

Wiping Excess: Wipe off any excess grease around the grease fittings to prevent dirt.

Post-Lubrication Rotation: After lubrication, rotate the bearing several times to ensure the grease is spread evenly.

Clean Up: Clean up any spilled grease to maintain a clean working environment.

Maintenance Schedule: Follow the manufacturer's recommended maintenance schedule for future lubrication.

Record Keeping: Keep a record of the lubrication date and the type of grease used for future reference.

Visual Inspection

Regular visual inspections of slewing rings are vital to spot problems early, like cracks, broken seals, rust, and wear. These problems that can cause equipment failure if not fixed.

During maintenance inspection, look for signs of damage, check seal integrity, assess corrosion and lubricant condition, and how everything is lined up. Also, watch out for anything that's too loose or swollen. Keep things clean to stop wear from dirt. Address any findings promptly to avoid further damage.

By checking the bearings regularly, you can prevent unexpected downtime, extend the bearing's life, ensure safety, and maintain performance.

Noise and Vibration Monitoring

Strange noises and vibrations might be signs that there's an issue with the bearings. This could be due to misalignment, insufficient lubrication, or wear and tear. If you hear a squealing sound, it could mean that the bearing needs more lubrication. A grinding noise could mean the parts are rubbing together because they're worn. Paying attention to these signs is crucial to fix things before they get worse.

Bearing Health Monitoring Techniques

Clearance Measurement

Checking how much a bearing can tilt is important to see if a slewing bearing is wearing out. When a bearing gets worn out, it may result in increased tilt. This could lead to poor performance and failure.

Follow the steps to measure clearance:

If the space for tilting increases gets bigger than it should, it means the bearing is worn and might need maintenance or replacement.

Clearance measurement prevents unexpected equipment breaking down and makes sure everything runs safely.

Proper bolt tightening ensures even load distribution and prevents misalignment. If the bolts are not tight enough, it can cause issues like the bearing race deformation, increased friction, and ultimately, bearing failures.

Use a special tool called a torque wrench and follow the right order for tightening the bolts. This makes sure the bolts are as tight as they should be, which helps the bearing stay in good shape and last longer. This practice is crucial for the reliable operation of machinery and the safety of personnel.

Once your machine has run for 100 hours, check the bolts on the slewing bearing and make sure they're as tight as the maker recommends. Use the right amount of torque when you do this. After that, check them every 500 hours or once a year, whichever happens sooner.

If you see any bolts signs of fatigue, such as thread wear, elongation, or corrosion, replace them right away. Always use the correct grade and length of bolts and follow the recommended tightening sequence.

Seal Inspection and Replacement

Role of Seals in Bearing Protection

Seals on slewing bearings form a shield to protect bearing internal components against dirt and debris. They also create a seal with the bearing housing, helping to retain lubricant and maintain optimal operating conditions.

Check the seals regularly to ensure they're working well.

Seal Inspection Process

Regular Inspection: Conduct routine checks for any cuts, cracks, or deformation in the seals.

Follow these steps to ensure seal can work smoothly and effectively.

Careful handling of slewing bearings is crucial to prevent damage from drops or impacts. Use designated lifting points such as eyebolts or hoist rings. Avoid tilting or striking the bearings during transport to safeguard their precision components.

The basic rules for handling and storing slewing bearings work for all kinds, but there are special things to keep in mind for cross roller, single, double, and triple row roller bearing types because they're made differently and can handle different amounts of weight.

Always follow the maker’s guidelines for safe handling and storage.

Careful handling of slewing bearings is crucial to prevent damage from drops or impacts. Use designated lifting points such as eyebolts or hoist rings. Avoid tilting or striking the bearings during transport to safeguard their precision components. Always follow the supplier’s guidelines for safe handling and storage.

Understanding hole patterns and the specific handling and storage requirements for different types of slewing ring bearings, and you can ensure their best performance.

Increased clearance, abnormal noise, reduced load capacity, and vibration are signs of excessive wear in slewing bearings. When such signs are observed, it is deemed necessary to replace the bearings. The decision to repair or replace the bearings depends on the extent of damage, cost of repair compared to buying new ones, and how important they are for the application.

Generally, if the cost of repair is much lower than a new bearing and the repair can restore the bearing to near-original condition, it's better to repair.

However, if the bearing is severely damaged or the repair cost is high, replacement is more economical. When analyzing cost-benefit, you should consider downtime, safety, and the potential for future failures.

To keep slewing bearings in top shape, regularly apply lubricant, give them thorough inspections, ensure the bolts are tightly secured just right, and monitor the condition of the seals. Adhere to this routine and your machines will run more smoothly with longer service life. For a reliable maintenance schedule and advice from the experts, get in touch with LILY Bearing.

Radial and axial loads apply force in different directions, and using the wrong bearing type can lead to premature wear, system inefficiencies, or...

Full complement bearings are often overlooked in the assembly of bearings. Unlike rubber seal, steel seal, open type, and UG bearings that we are...

Kaydon is known for leading the bearing technology. Kayddon bearings offer creative ways to ensure longer service life of bearings. They are great at...