How to Extend the Life of Your Slewing Ring Bearings

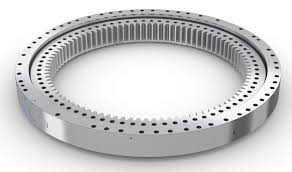

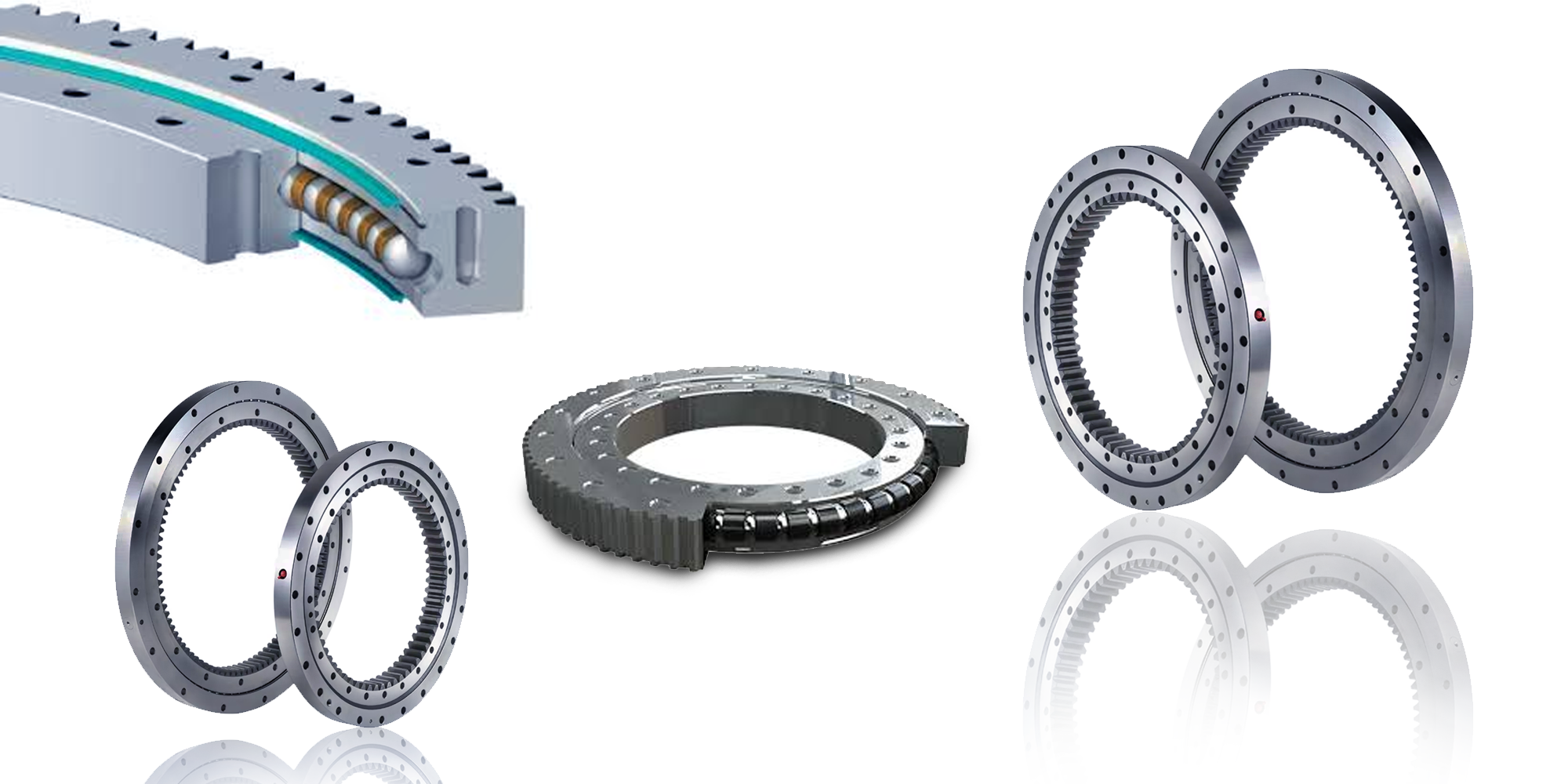

Understand the Importance of Slewing Ring Bearings We call slewing ring bearings, turntable bearings or slew ring bearings. They are large-diameter...

Slewing bearings are critical components in machinery, designed to manage axial loads, radial loads, and moment loads, ensuring stable operation in applications like construction and wind turbines. Dimensional accuracy is vital for their performance, longevity, and safety, particularly in heavy-duty use. This blog aims to offer insights and actionable steps to maintain dimensional precision in slewing bearings, crucial for reliable machinery function.

Critical dimensions in slewing ring bearings, such as raceway curvature radius and contact angle, significantly influence load capacity and service life.

Tolerances for inner and outer diameters and bearing clearance are essential for ensuring proper fit and performance.

These specifications are key factors that affect slewing bearings’ efficiency and longevity under various operating environment. They must be meticulously maintained to guarantee.

Materials like 42CrMo and GCCR15 are crucial for slewing bearing accuracy, providing the necessary strength, wear resistance and corrosion resistance.

Heat treatment plays a vital role in enhancing dimensional stability; it ensures components maintain their shape and size under load, preventing deformation. This process is essential for the long-term performance and high precision of bearings in demanding applications.

Forging quality is paramount in establishing the base structure of slewing bearings, ensuring the material's density and reducing dimensional deviations. The process refines the steel's internal structure, enhancing strength and uniformity.

Utilizing CNC-controlled rough and fine turning ensures consistent and precise results, critical for the bearing's performance and longevity in various applications.

Induction hardening enhances surface hardness by selectively hardening critical areas, minimizing dimensional changes through precise heat treatment, thus preserving bearing dimensions and durability.

Maintaining uniform hardness and layer depth across the raceway is essential for load distribution, ensuring bearing longevity and operational reliability. This precision process guarantees consistent performance and extended service life.

Precise drilling ensures accurate mounting hole alignment, crucial for secure assembly. Gear teeth cutting with exact specifications is vital for maintaining proper meshing and smooth operation in slewing bearings.

Verifying alignment and adhering to tolerances during these processes guarantees accurate fit and performance, which are essential for load distribution and the bearing's service life. Misalignments and deviations can lead to premature failure, making stringent quality checks indispensable.

During pre-assembly inspection of slewing bearings, components including rings, balls/rollers, and spacers are meticulously inspected for defects and cleanliness. This process ensures that all elements meet stringent quality standards, critical for maintaining bearing performance and extending service life.

This process is critical to ensure surface integrity, as contaminants or imperfections can lead to premature failure.

Defect-free surfaces are essential for optimal performance, load distribution, and the longevity of the bearings in operation.

Checking rotational smoothness and making preload adjustments during assembly are crucial for ensuring even load distribution and optimal performance of slewing bearings. These checks prevent mechanical stress and potential early failure, thus enhancing the bearing's lifespan and the machinery's reliability. Proper preloading is essential for accurate operation and longevity of the bearings.

Methods for assessing load distribution accuracy include dynamic load testing, torque measurements, and utilizing condition monitoring technologies to verify operational efficiency and bearing performance under actual working conditions.

Proper alignment is essential for longevity and smooth operation of the bearing under load.

To align slewing bearings with mating surfaces and avoid stress concentration, ensure perpendicularity and surface flatness. Use precision tools like dial indicators to check for parallelism, and adjust as necessary. Maintain cleanliness to prevent foreign articles, and avoid overtightening, which could cause deformation.

The importance of uniformly tightening bolts in a star pattern during assembly cannot be overstated; this method helps to distribute clamping forces evenly, reducing the risk of bearing deformation and ensuring optimal load distribution throughout the bearing.

Calibration is pivotal in reducing eccentricity and ensuring concentricity in slewing bearings. It fine-tunes the fit between components, aligning them perfectly to achieve uniform load distribution and smooth operation. This precision is essential for maintaining bearing accuracy, enhancing performance, and prolonging the service life of the machinery.

Monitoring gear meshing and making necessary backlash adjustments is critical for maintaining smooth operation, preventing excessive wear, and ensuring the precision and longevity of the bearings. Proper calibration and gear alignment are essential for the efficient functioning of machinery driven by slewing bearings.

Proper lubrication is essential in slewing bearings as it forms a protective film between rolling elements and raceways, preventing direct metal contact. This reduces wear, maintains surface smoothness, and minimizes friction, thereby extending the bearing's service life and ensuring reliable operation.

Routine inspections are essential for the early detection of wear, corrosion, and deformation in slewing bearings, which are critical for machinery reliability.

It is highly recommended to replace components that exhibit signs of fatigue or damage promptly. This proactive maintenance ensures operational efficiency, extends equipment life, and prevents unexpected failures.

For ensuring the precision and integrity of slewing bearings, it is recommended to employ advanced tools such as coordinate measuring machines (CMM) for accurate dimensional inspections.

Additionally, non-destructive testing (NDT) plays a crucial role in identifying internal flaws without compromising the component's integrity, ensuring the reliability and longevity of the bearings in service.

CAD and simulation software are instrumental in optimizing slewing bearing designs by predicting dimensional changes and stress points. These tools enable engineers to simulate real-world conditions, ensuring designs are robust and efficient.

Adoption of smart manufacturing technologies allows for real-time monitoring and enhances quality control, crucial for maintaining the precision and performance of bearings throughout the production process.

To ensure dimensional accuracy in slewing bearings, select precise materials, employ CAD, machine accurately, inspect with CMM, and maintain regularly.

Precision is vital for optimal performance and extended lifespan. Prioritize accuracy in all stages—from design to maintenance—to achieve maximum operational reliability for high quality slew bearings.

Understand the Importance of Slewing Ring Bearings We call slewing ring bearings, turntable bearings or slew ring bearings. They are large-diameter...

Acting as the key "hinges" in large machines like cranes and excavators, slewing ring bearings enabled them to rotate smoothly and with precision in...

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...