Slewing Bearing and Jib Crane Bearing Guide

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...

Slewing bearings are important parts of renewable energy systems, like wind turbines and solar trackers. They help these systems rotate smoothly and handle heavy loads while staying perfectly aligned. In this way they capture as much energy as possible to create cleaner, more sustainable power.

In this blog, we’ll explore how slewing bearings help improve the efficiency of renewable energy systems.

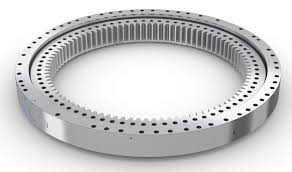

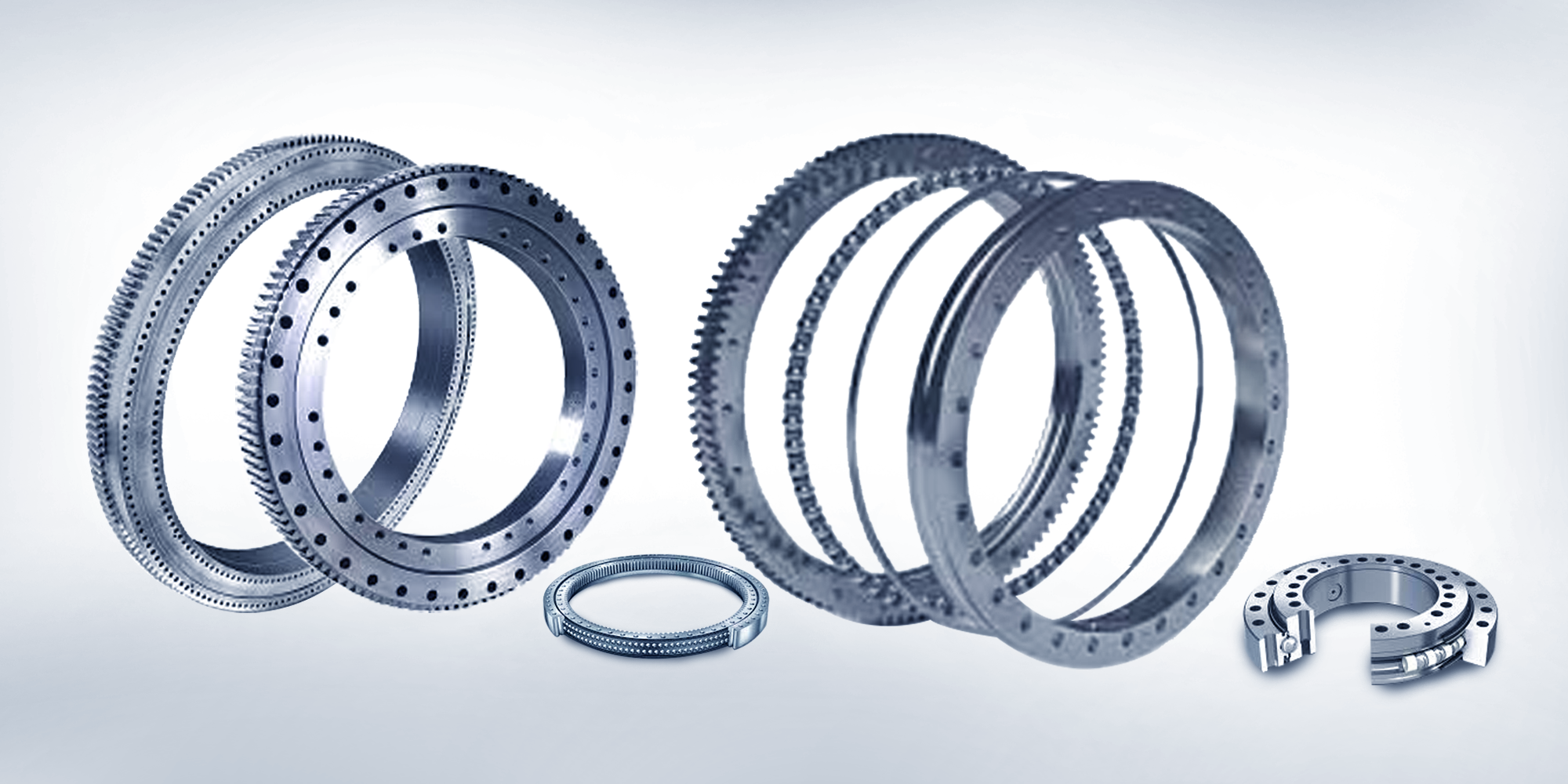

Slewing bearing, also known as slewing rings, slewing ring bearings or turntable bearings, are large rolling bearings. They can handle heavy-duty tasks that involve rotation.

They have an inner ring and an outer ring, with rolling parts like balls or rollers in between. These parts help the bearing rotate smoothly while supporting heavy weights.

Some slewing bearings also come with built-in gears, which allows for precise movement and positioning. This makes them especially useful in things like wind turbines and solar trackers, where accuracy and strength are key.

Slewing bearings help components make rotational movement by supporting axial, radial, and moment loads at the same time. This makes them great for handling tough and changing conditions in renewable energy sectors.

They make sure parts spin smoothly and just right, even when things like wind speed change or the sun moves to a different angle. This reliability is key for capturing as much energy as possible and keeping renewable energy systems running efficiently.

Slewing bearings provide stable, precise rotation for wind turbine blades and solar trackers. Bearings for wind turbines adjust blade angles to capture maximum wind energy.

In solar systems, slewing bearings help panels follow the sun for optimal sunlight exposure. They're able to handle heavy loads and maintain accuracy in changing conditions. This helps renewable energy systems improve their the efficiency and reliability.

High-quality slewing bearings ensures smooth and accurate operation. They can handle heavy loads and resist wear so that less maintenance is necessary. They are robust and reliable enough to consistently harness energy, even in challenging conditions. This extends the lifespan of wind turbines and solar trackers.

Wind energy slewing bearings enable precise blade angle adjustments in wind turbines, maximizing energy capture as wind speeds vary. Their accuracy and load carrying capacity ensure reliable performance, enhancing turbine efficiency and power output.

Slewing bearings let the nacelle (the top part of the turbine) rotate and face the wind. They help the yaw system stay on track, so the turbine faces the wind just right.

They help capture the most energy and generate power efficiently. This helps the turbine generate power efficiently, even when the wind changes direction.

Slewing bearings help wind turbines transfer energy from the spinning blades to the generator. They connect the main shaft to the generator, supporting heavy loads and keeping everything aligned for smooth energy conversion.

Slewing bearings help solar panels rotate smoothly to follow the sun, maximizing sunlight exposure and energy capture. They’re key to single-axis trackers, ensuring panels adjust accurately throughout the day. Their durability keeps systems efficient and reliable, even in changing weather.

In solar trackers with two axes, slewing bearings let the panels move up and down and side to side at the same time. This helps the panels follow the sun all day and through the seasons. This maximizes sunlight exposure, optimizing energy capture and significantly boosting solar power efficiency throughout the day and year.

Slewing bearings support turbine rotors, ensuring stable, precise rotation for efficient energy conversion. In hydroelectric systems, they handle high-speed rotation and heavy loads. Their durability and reliability enhance turbine performance and lifespan, making them essential for long-term, efficient operation.

Slewing bearings support precise rotation under changing water flows and tidal forces. They ensure smooth operation in hydroelectric and tidal systems They handle dynamic loads and pressures, maintaining consistent performance. Their durability and wear resistance boost reliability in tough aquatic environments.

High-grade materials like hardened steel ensure slewing bearings are strong, durable, and wear-resistant. They meet industry standards for renewable energy systems. They can SU heavy loads, high stresses, and harsh conditions in wind, solar, and hydro applications.

High-quality bearings provide smooth, precise rotation, reducing friction and wear, enhancing efficiency, and extending service life. This lowers maintenance costs and replacements while ensuring consistent operation, optimal energy capture, and maximum power output for sustainable energy systems.

Slewing bearings can be customized for specific projects, like adding external gears for precise control in wind turbines. Size variations ensure optimal fit and performance in renewable energy systems, enhancing energy capture, reliability, and efficiency.

Slewing bearings can be customized with various designs and features to suit renewable energy applications. You can choose from different load-carrying capacities for handling varying wind speeds. Also corrosion-resistant materials are available for offshore use, and integrated seals to keep dirt out.

Innovations such as induction hardening enhance bearing efficiency and resistance. This process provides a uniform and deep hardened layer on the bearing surface. This increases the bearing's load carrying capacity and reduces wear. And the bearings can improves its ability to handle extreme loads under harsh environmental conditions.

IoT and automation enable predictive maintenance and real-time monitoring of slewing bearings. Sensors track health, loads, and performance, detecting issues early to prevent failures. This reduces downtime, improves efficiency, and boosts system reliability in renewable energy applications.

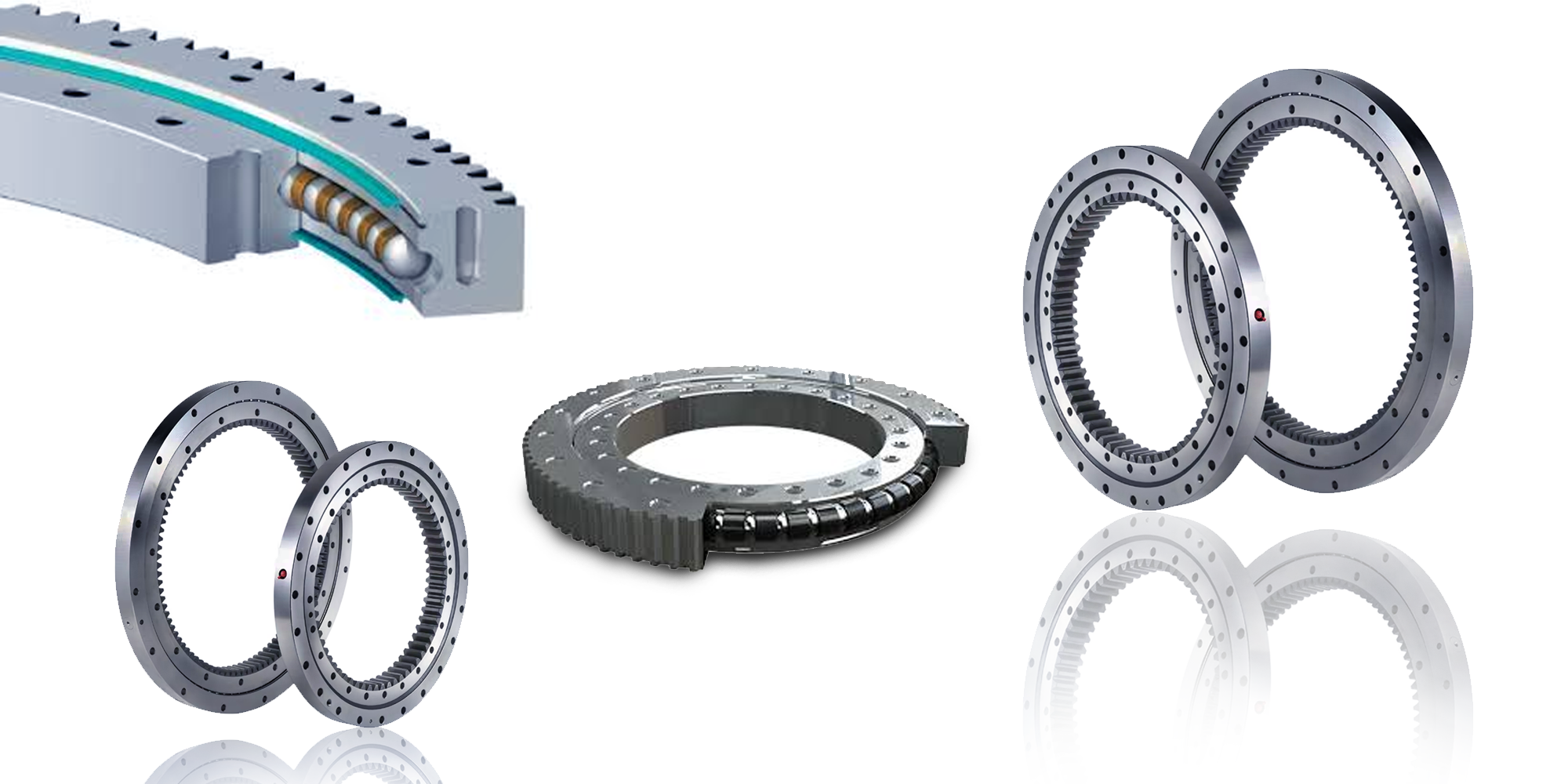

Ball slewing bearings feature a four-point contact design, providing exceptional moment, thrust, and radial load capacities. Ball bearings play a role in renewable energy systems such as wind turbines for pitch and yaw control. They support the rotor bearings and enabling precise blade angle adjustments.

Roller slewing bearings feature cylindrical or tapered roller elements, providing higher load capacities and making them ideal for heavy-duty renewable energy applications. Their design allows them to handle substantial radial, thrust, and moment loads simultaneously. This ensures reliable performance in large wind turbines and other demanding environments.

Single-row slewing bearings appear in smaller renewable energy applications because of their compact design and lower cost. They are so simple and easy to install. So they're suitable for applications with limited space and moderate load requirements.

Despite the advantages above, they have limitations. They have lower load carrying capacity and reduced ability to handle complex load combinations compared to multi-row designs. This restricts their use in larger or more demanding renewable energy systems.

Multi-row slewing bearings have multiple rolling parts. They perform well in handling heavy radial, thrust, and moment loads. They stay stable and reliable, even in dynamic, high-force situations. So, they're perfect for tough renewable energy uses, like lar wind turbines and heavy-duty solar systems.

Routine inspections of slewing bearings are crucial for identifying wear and tear early, preventing unexpected failures and costly downtime.

Proper lubrication with high-quality grease reduces friction, wear, and heat in slewing bearings. Regular, clean application ensures smooth operation, optimal performance, and longer bearing life in renewable energy systems.

Replacing worn slewing bearing parts prevents failures, maintains load capacity, and ensures efficiency. Timely replacements support smooth operation, reliability, and system lifespan, reducing downtime and costs while boosting energy production in renewable energy systems.

Moisture, temperature changes, and contaminants like dust can harm slewing bearings, causing corrosion, wear, and material degradation. These factors reduce efficiency, shorten lifespan, and increase maintenance needs.

Varying loads and high operating frequencies increase stress, wear, and heat in slewing bearings, reducing durability. Proper selection, design, and maintenance are essential to ensure reliability and longevity in renewable energy systems under these demanding conditions.

Slewing bearings are essential for the efficiency and reliability of renewable energy systems, providing durable and tailored support. Advanced technologies enhance their performance, making them crucial for sustainable energy solutions.

Explore advanced bearing solutions and contact LILY Bearing. We have experts at your service and tailored support to optimize your renewable energy projects.

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...

Slewing bearings are critical components in machinery, designed to manage axial loads, radial loads, and moment loads, ensuring stable operation in...

Slewing bearings, sometimes called slewing rings, slewing ring bearings, or turntable bearings, play a key role in machines that need to spin...