How Does a Slewing Bearing Work?

Slewing bearings, sometimes called slewing rings, slewing ring bearings, or turntable bearings, play a key role in machines that need to spin...

Table of Contents

Slewing bearings are essential in heavy machinery like cranes.

They allow jib cranes to function effectively with 360-degree movement for precise placement of loads.

They manage various loads, ensuring smooth operations.

This guide will help you understand why slewing bearings and jib crane bearings are important, how to choose the best ones for the job, and how to keep them running smoothly in heavy duty applications.

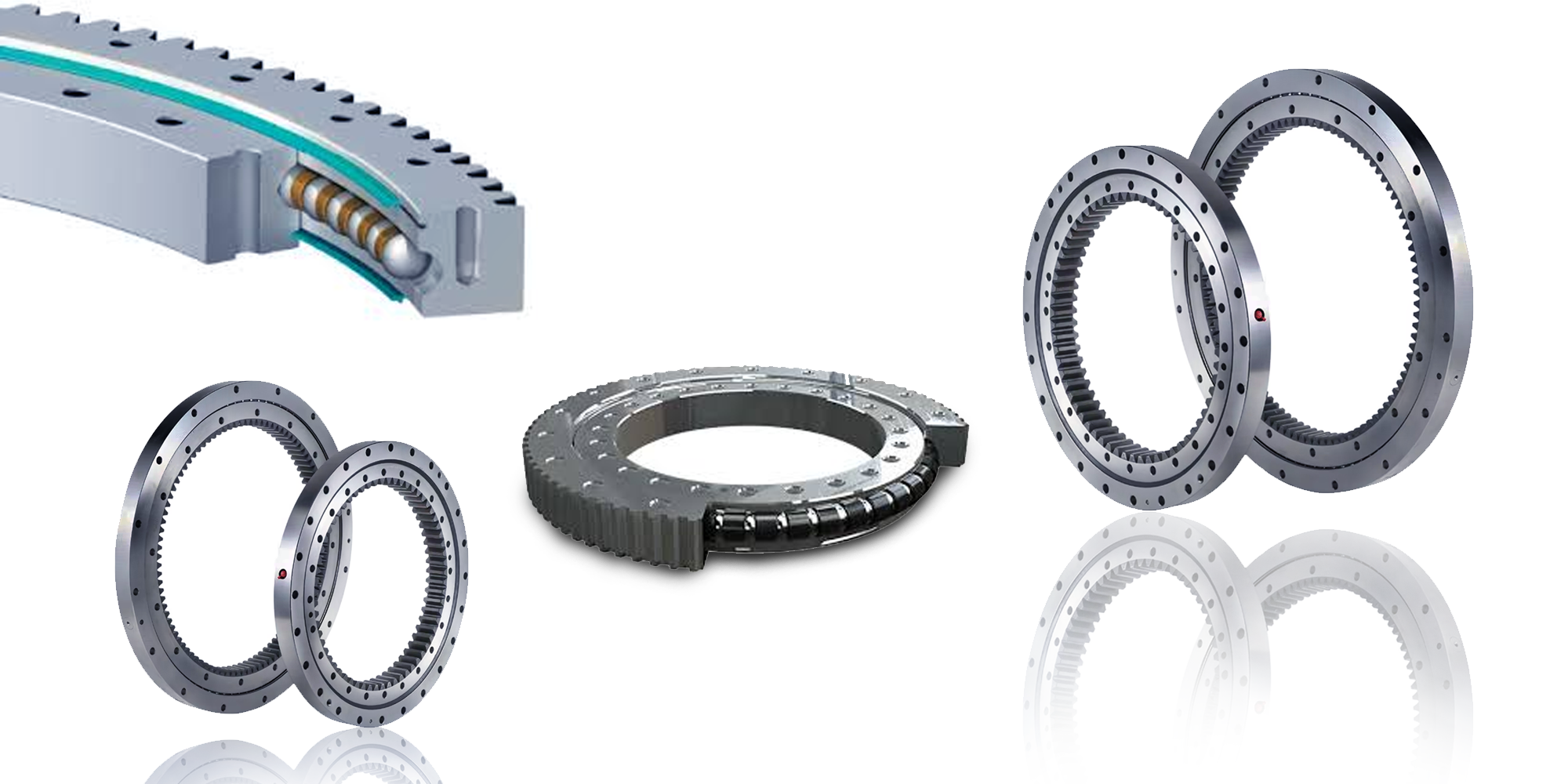

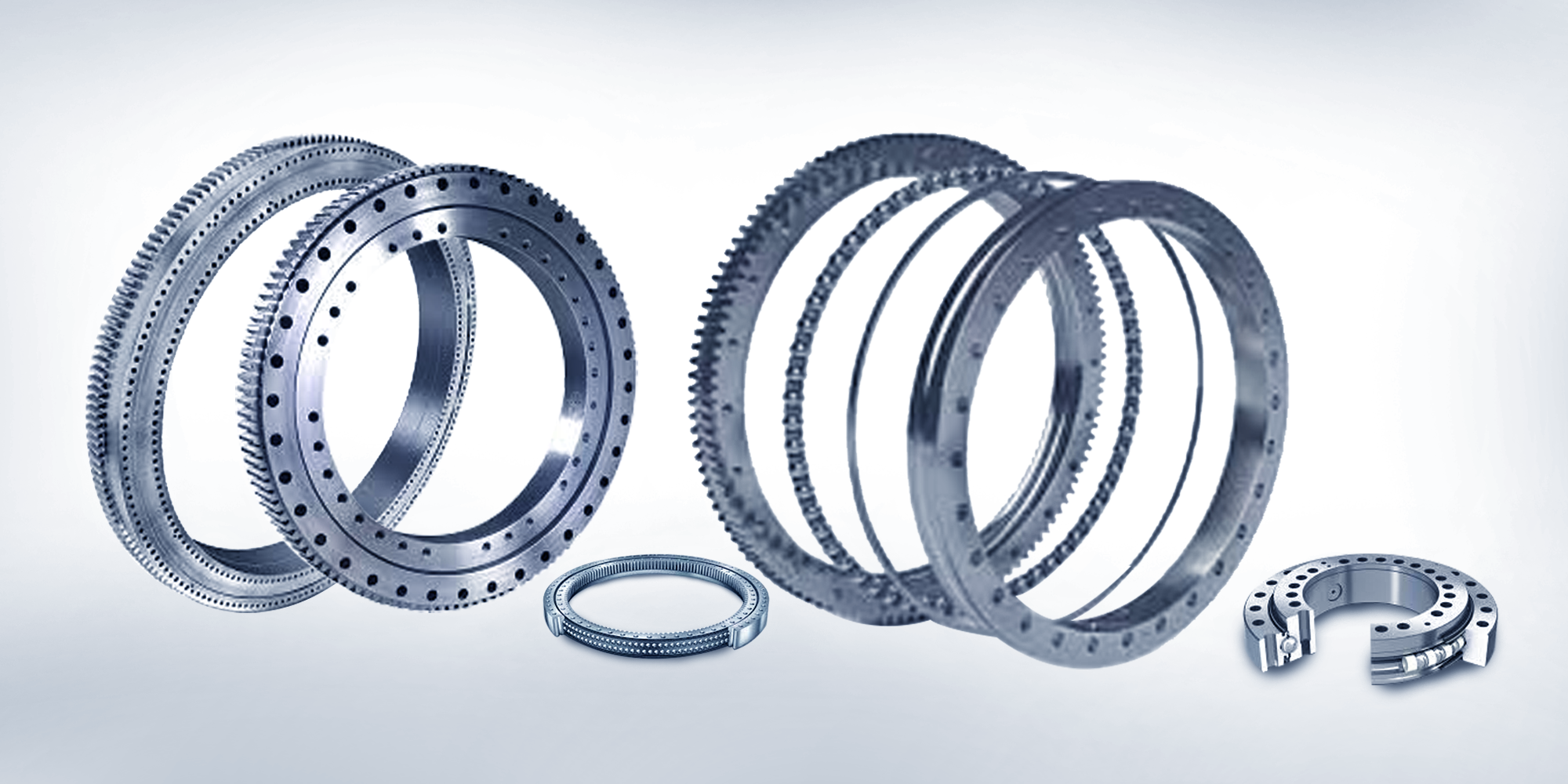

A slewing bearing is a large, circular bearing that permits 360-degree rotation around a vertical axis.

It consists of inner and outer rings, rolling elements, and seals.

They are designed to handle significant loads in cranes and heavy machinery.

Key components of slewing bearings include inner and outer rings, rolling elements, spacers, and seals.

These components work together to facilitate smooth rotation while withstanding substantial forces.

Ball slewing bearing, such as thrust ball bearings, use round balls as rolling elements, making them small and perfect for high-speed moving.

On the other hand, roller slewing bearings, such as crossed roller bearings and three-row roller bearings, use rollers that can be either cylindrical or tapered, which allows them to handle heavier loads.

They're perfect for situations where there's a lot of weight coming from the sides or pushing straight down.

Single-row slewing rings, such as single-row ball bearings, are ideal for lighter loads and where space is limited, offering precision and speed.

They're commonly used in applications like small cranes and light-duty machinery.

Double-row rings, such as double-row ball bearings, are stronger and can handle more weight.

They are perfect for larger and heavier machines like excavators and dump trucks that need to handle tough jobs.

Three-row rings are capable of handling the toughest jobs, giving extra support for huge loads.

You'll usually find them in large cranes and heavy industrial equipment which require extreme loads and durability.

Some slewing bearings have gears built right into them, which makes them internal gear bearings.

Others have their gears separate, known as external gear bearings.

Bearings without gears need something from outside to help them move.

The choice depends on the specific requirements for load handling and control.

Slewing bearings spread out the load in a superior way, are easy to maintain, and can deal with all sorts of heavy and complicated loads.

This is the reason why they are ideally suited for the operation of heavy-duty cranes.

A jib crane has a long, straight arm that sticks out and can rotate a full circle.

This provides flexibility in lifting and positioning loads.

The structure typically includes a jib arm, a king post, and a slewing bearing mechanism.

Slewing bearings allow the jib arm spin up and down on a vertical line, which helps you put loads exactly where you want them with good control.

They are essential for making sure the crane operates efficiently and safely.

Picking the right bearing for a jib crane means thinking about load capacity, type of movement, and environmental conditions.

Choosing the correct bearing helps make sure the crane works well and lasts a long time.

Knowing these ensures a bearing can help handle the forces exerted during operation.

Precise dimensions ensure proper fit and maintain alignment of the parts.

They're vital for optimal performance, load distribution, and the long service life of the bearing and its components.

Common materials like 42CrMo and special coatings help make the bearings stronger and more able to resist wear, rust, and the effects of weather.

Gear module and pressure angle are critical for bearing performance with gears.

Module affects gear size and strength, while the pressure angle influences how teeth mesh, ensuring smooth operation and longevity.

Other criteria for selecting slewing bearings include operating speed, temperature range, and environmental conditions, which influence the bearing's material choice and design.

For smooth installation of jib crane slewing bearings:

Follow the instructions provided by the maker for using and maintaining the jib crane slewing bearings.

This way you can ensure correct installation, prevents damage, and maintain warranty coverage for jib crane slewing bearings.

For slewing bearings, grease every 100 hours under normal conditions, more often in harsh environments.

Use lithium grease for general use, polyurea for heavy loads, aluminum for wet areas, and synthetic for extreme temperatures.

Clean gently with seal-safe solvents, removing old grease before lubricating again.

Consider environmental impacts: dust, moisture, and temperature can alter maintenance needs and grease performance.

Routine maintenance prevents breakdowns, reduces costs, and ensures safety by avoiding unexpected machine startups, which can lead to injuries.

Always ensure power is off during maintenance.

Common signs of wear and damage include unusual noise, vibrations, and increased clearance.

If you notice any of these signs, it's time to inspect and handle the problem.

Fixing Common Crane Issues:

Preventive Maintenance Tips:

By keeping your crane's slewing bearings well-maintained and lubricated, you can improve their performance by reducing friction and wear.

This helps your crane last longer and avoid serious breakdowns, and minimize the need for frequent repairs so as to ensure your crane stays reliable and runs for a long time.

These bearings boost safety and cut the chance of breakdowns, keeping operations steady.

Expertly crafted for seamless crane turns, they minimize friction and maintain perfect alignment, reducing wear and extending life.

Made with robust steel like 42CrMo4, they handle heavy loads and rough conditions, which makes them very reliable.

High-quality slewing and jib crane bearings save long-term costs by lasting longer and reducing breakdowns.

They handle heavy loads with less wear, needing fewer replacements and repairs, which cuts maintenance expenses.

Case Study of Slewing Bearing Performance in a Jib Crane Application

In a specific project with Demag Cranes & Components, we faced a challenge with their heavy-duty jib cranes (rated for class H2 lifting).

The goal was to make these cranes operate more smoothly with less effort for both moving and rotating.

This was because of their well-designed trolleys and special bearings that made the cranes glide effortlessly.

Demag tackled these issues by using high-tech materials and exact engineering for their slewing bearings.

This kept friction and wear to a minimum, which in turn saved energy and made the cranes last longer.

The result was safer and smoother lifting work, along with a lot less maintenance cost and downtime.

This shows how well high-quality slewing bearings work in tough jib crane jobs.

This guide helps you understand the ins and outs of Slewing and Jib Crane Bearings.

It covers what they are, how to choose the right ones, and how to keep them in top shape for better performance and longer life.

Picking the right bearing for jib cranes saves money, reduces breakdowns, and boosts safety over time.

For the best results and safety, always reach out to LILY's team and follow the maker's instructions.

Slewing bearings, sometimes called slewing rings, slewing ring bearings, or turntable bearings, play a key role in machines that need to spin...

Crane slewing bearings are essential parts that let cranes make their full 360-degree turns. This ability is crucial for handling various lifting...

Slewing bearings, also known as slewing rings or turntables bearings, facilitate rotational movement while supporting heavy loads. They are essential...