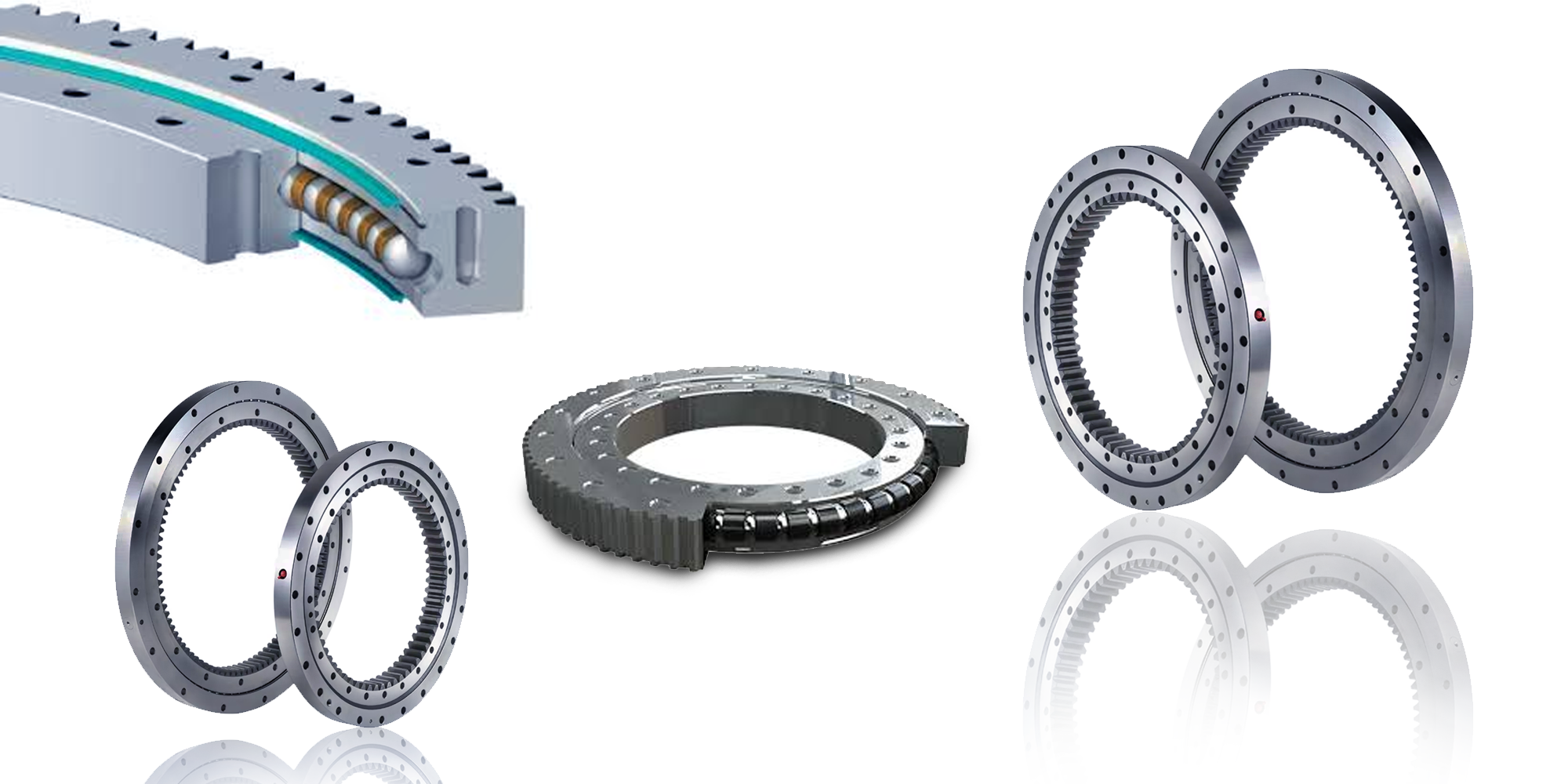

Slewing Bearing and Jib Crane Bearing Guide

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...

Table of Contents

Bearings are mechanical parts that support and guide rotating or moving components, like shafts or wheels, while minimizing friction.

Sleeve Bearings and Ball Bearings are two main types of bearings.

Sleeve bearings have a smooth cylinder design for sliding motion, ideal for low-speed, heavy loads.

Ball bearings use rolling balls to reduce friction, making them great for high-speed, precise uses like cars and machines.

Choosing the right bearing type is crucial for ensuring high performance, reliability, and longevity of machinery.

This blog compares sleeve bearings and ball bearings to help readers choose the right one for their needs.

.jpg?width=501&height=400&name=%E6%9C%AA%E6%A0%87%E9%A2%98-1_compressed%20(1).jpg)

Sleeve bearings, also called plain bearing or journal bearings, are cylindrical in shape.

They support motion using a sliding surface instead of rolling parts.

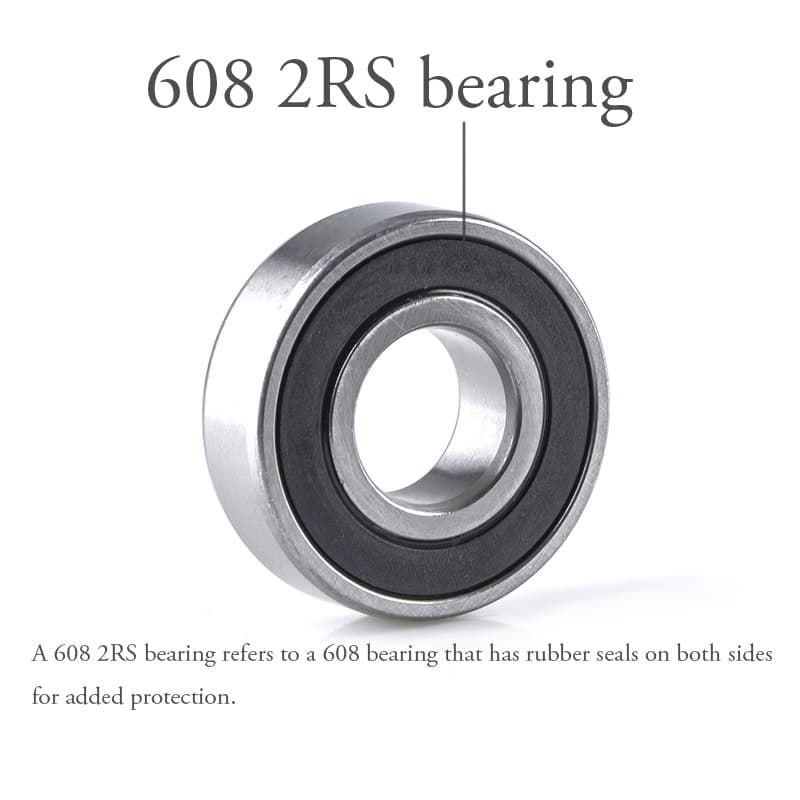

What is a Ball bearing? A ball bearing is a type of rolling-element bearing. It uses spherical metal balls to keep the bearing races separated.

Ball bearings are designed to reduce friction between moving parts. They provide smooth rotation and support for both radial loads and axial loads.

Ball bearings offer four main parts:

Ball bearings are versatile because they can handle both radial loads and axial loads.

The rolling balls evenly distribute these forces, allowing smooth and efficient operation in multiple directions.

This flexibility makes ball bearings ideal for applications with combined or changing load conditions. They are commonly used in motors, gearboxes, and rotating machinery.

Sleeve bearings are primarily designed to handle radial loads, which act perpendicular to the shaft.

They provide smooth motion when the shaft slides along the bearing surface.

However, sleeve bearings have limited or no capacity to handle axial (thrust) loads, which act along the shaft.

This makes them less suitable for applications where both radial and axial loads are significant.

|

Feature |

Sleeve Bearing |

Ball Bearing |

|

Structure |

Simple sleeve with no rolling parts. |

Has balls between inner and outer races. |

|

Friction |

Higher friction (sliding). |

Lower friction (rolling). |

|

Load Capacity |

Good for low-speed, low-load. |

Good for high-speed, high-load. |

|

Size and Design |

Simple and compact. |

More complex design. |

|

Lubrication |

Needs lubrication to work well. |

Needs lubrication, but less often. |

|

Durability |

Wears faster under heavy loads. |

Lasts longer under high speeds. |

|

Cost |

Usually cheaper. |

Usually more expensive. |

|

Applications |

Used in fans and low-speed machines. |

Used in high-speed machinery and motors. |

Sleeve bearings are ideal for low-speed, low-load applications.

Examples include home appliances, low-power fans, and quiet office equipment.

Their lower cost and quieter operation make them suitable for less demanding environments.

Sleeve bearings are good for short-term use in a vertical position where they are not exposed to high temperatures.

In this setup, sleeve bearings handle light loads and are effective for temporary applications. They keep costs low and perform well in less demanding conditions.

Ball bearings are perfect for high-speed, high-load uses in automotive, industrial machinery , pumps, and HVAC systems.

They provide smooth, reliable performance, handling both speed and heavy loads. This helps equipment run efficiently and last longer.

Ball bearings are ideal for long-term, high-temperature environments, offering durability and efficiency over time.

They can handle high heat while maintaining low friction.

This makes them perfect for automotive engines, industrial machinery, and aerospace applications where reliable, long-lasting performance is crucial.

This helps reduce maintenance and extend the life of equipment.

The choice of bearing depends on the operating life and environmental conditions.

Ball bearings are best for long-lasting use, like in automotive engines or industrial machinery.

Sleeve bearings are suitable for short-term or cost-sensitive needs.

Heat-resistant materials like ceramic or treated steel are used in high-temperature environments.

Sealed ball bearings work well in dusty conditions. For humid or corrosive environments, stainless steel or ceramic bearings resist rust.

The right bearing balances performance, durability, and cost based on these factors.

Choose the bearing based on your application, operating temperatures, and budget. For low-speed, light-load uses, sleeve bearings are more affordable. Ball bearings are more suitable for high-speed, heavy-load, or long-term applications, although they come at a higher cost. Consider factors like environment and lifespan when making your choice.

Make sure to carefully assess your needs before choosing a bearing. If unsure, it's smart to consult lily bearing to pick the best option.

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...

Bearings are essential parts of machines and equipment. They reduce friction, making it easier for parts to move smoothly. Two main types of bearings...

Industrial bearings play an integral role in the operation of various machinery and vehicles, reducing friction and enhancing performance. This blog...