How Ball Bearings Improve Machinery Performance

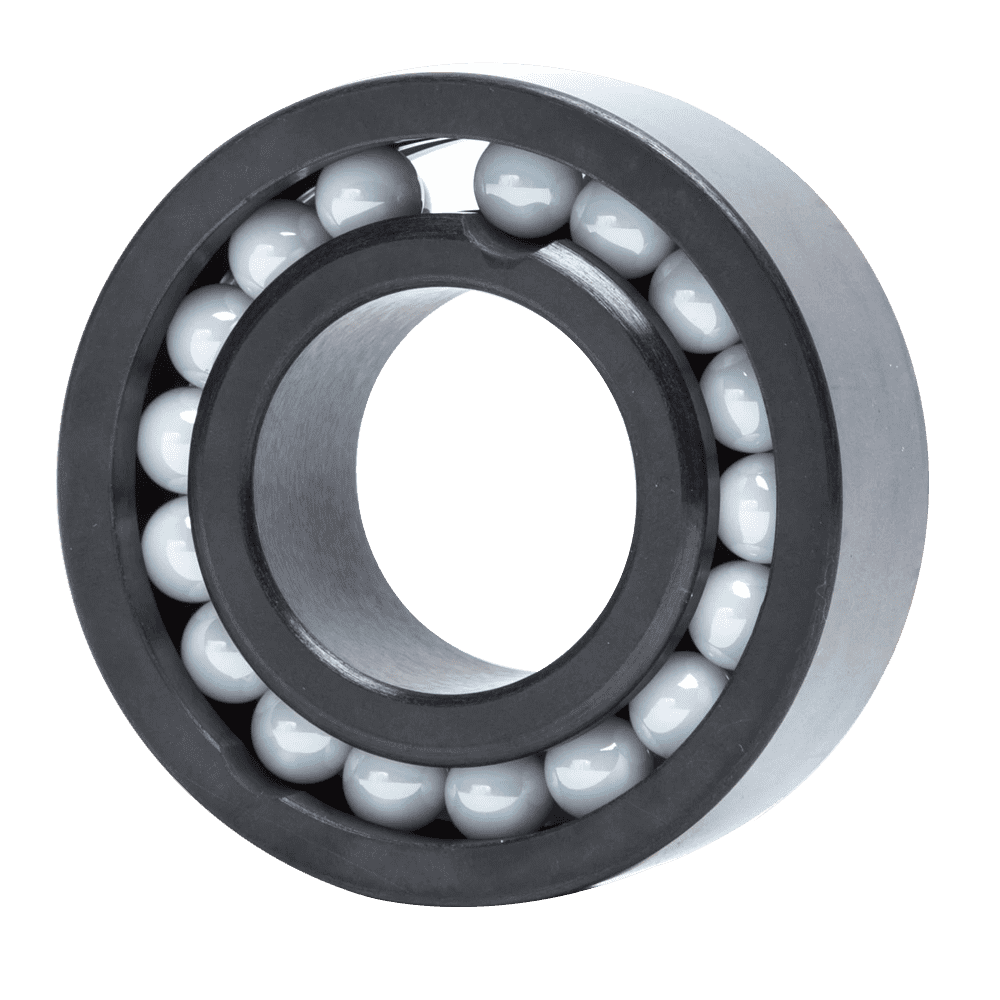

Ball bearings are bearings that use spherical balls to keep the inner and outer races apart. They reduce friction between moving parts, enabling...

Silicon Nitride Balls are ceramic balls made from silicon nitride (Si₃N₄). This material is known for its excellent hardness, resistance to wear, and thermal stability. These balls are highly precise and have a low density. This makes them lighter and more durable than steel balls in many applications.

Silicon nitride balls are used in high performance bearings because they are durable and lightweight. They are also resistant to wear, heat, and corrosion. They extend bearing life, reduce friction, and improve efficiency, making them ideal for high-speed, aerospace, and harsh environments.

Reducing friction in bearings is key to improving efficiency and extending their lifespan. Less friction means less heat, which reduces wear and prevents overheating. This leads to smoother performance, lower energy use, and longer-lasting bearings. This results in fewer maintenance needs and cost savings.

Silicon nitride balls have lower friction than steel balls, which improves efficiency and reduces heat. They are more wear-resistant, lasting longer than traditional materials. Their lightweight and strong design make them better suited for high-speed applications.

In Aerospace:

In Automotive:

In Bicycle Wheel Hubs:

|

Property |

Silicon Nitride |

Steel |

|

Heat Generation |

Lower heat generation because of low friction. |

Higher heat generation because of higher friction. |

|

Coefficient of Friction |

0.1 to 0.2 |

0.3 to 0.5 |

|

Operating Temperature |

Can withstand up to 1000°C (1832°F) |

Typically withstands up to 150-250°C (302-482°F) |

|

Thermal Stability |

Excellent, retains strength at high temps |

Loses strength and performance above certain temperatures |

|

Impact of Heat |

Less heat buildup, maintains performance |

Excessive heat can cause overheating and wear |

Compare the lifespan of bearings with silicon nitride balls to those with steel balls:

Silicon nitride balls are great for bearings because they reduce friction. This makes them more efficient by producing less heat and saving energy. They last longer, even under heavy use, and can handle high speeds and tough conditions.

They're also resistant to rust and can work in high temperatures. This makes them reliable and reduces the need for frequent maintenance.

Silicon nitride balls are useful in many industries. In automotive, they reduce friction, improve fuel efficiency, and last longer. In aerospace, they handle high speeds and temperatures, reduce weight, and improve fuel use.

In sports, like bicycles and skateboards, they provide smooth motion, last longer, and need less maintenance. Overall, they help improve performance, durability, and efficiency.

Silicon nitride balls bring many benefits, like reducing friction and improving performance. They are ideal for automotive, aerospace, and sports equipment applications. For bearings that offer extended durability and enhanced efficiency, consider silicon nitride balls. Upgrade today for smoother operation and less maintenance.

Ball bearings are bearings that use spherical balls to keep the inner and outer races apart. They reduce friction between moving parts, enabling...

Bearings are often unseen, yet they play a fundamental role in ensuring the smooth and efficient functioning of countless machines, devices, and...

Mounted bearings are essential for industrial machines. They support and stabilize rotating shafts, ensuring they stay aligned and reduce friction....