Shielded Vs Sealed Bearings

Bearings play a crucial role in numerous applications, reducing friction and enabling smooth, efficient operations. Among the wide range of bearing...

Silicon nitride balls are ceramic balls made from silicon nitride, a strong and heat-resistant material. They are used in precision bearings for applications that require high performance. This includes industries like aerospace, medical devices, and high speed machinery. Their durability and resistance to wear make them ideal for these demanding uses.

This blog will explore the key properties of Silicon Nitride Balls and their wide range of uses. We’ll look at why these si3n4 ceramic balls are perfect for high-performance bearings. They are used in industries like aerospace, medical devices, and high-speed machinery.

Silicon Nitride ceramic Balls have several advantages over steel balls. They create less friction, are lighter, and can handle higher temperatures. This makes them more durable and efficient in tough conditions.

Silicon Nitride Balls are 60% lighter than steel balls, offering significant advantages in applications where weight reduction is critical. This makes them ideal for high-speed applications, where their lighter weight enhances performance. It also reduces energy consumption and helps extend bearing life.

The lightweight nature of Silicon Nitride Balls reduces centrifugal force during high-speed rotation. This helps prevent the balls from being pushed outward. This reduces skidding and ensures smoother, more stable movement. As a result, there is less wear on both the balls and the bearings, improving overall durability and performance.

Silicon nitride si3n4 is twice as hard as steel, which makes it highly resistant to wear. This high hardness helps prevent damage from friction. As a result, the balls last longer and maintain their precision, even under tough conditions.

Because of their high hardness and wear resistance, Silicon Nitride Ball bearings have a much longer service life compared to steel balls. This makes them ideal for precision applications, where long-term durability and consistent performance are crucial.

Silicon Nitride has low friction properties. This reduces resistance during movement. As a result, ceramics bearings can operate at higher speeds. It helps maintain smooth and efficient performance.

The non-porous surface of Silicon Nitride Balls contributes to their low friction. This feature also reduces the need for lubrication. As a result, the balls are more efficient and easier to maintain in high-performance applications.

Silicon Nitride Balls can handle temperatures up to 1800°F (980°C), making them perfect for high-temperature environments. This heat resistance keeps them strong and durable, even in extreme conditions, ideal for industries like aerospace and automotive.

Silicon Nitride is highly resistant to corrosion. It can withstand harsh chemicals and tough conditions. This makes it ideal for demanding applications. Silicon Nitride is ideal for chemical processing and high-performance machinery applications.

Silicon Nitride Balls are electrically insulating, meaning they do not conduct electricity. This property helps prevent electrolytic corrosion, a common issue in electric motors. By not allowing electric currents to pass through, Silicon Nitride Balls protect the bearings and other components from damage. This ensures longer service life and more reliable performance in electric motors.

Silicon Nitride Balls are non-magnetic. This makes them ideal for applications where magnetic interference must be avoided.

They do not interfere with sensitive equipment. This includes applications like MRI machines and precision electronics.

Silicon Nitride Balls are used in aerospace applications because they are strong, heat-resistant, and durable. In satellites, they keep bearings precise. In aircraft turbines, they improve efficiency by withstanding high temperatures and reducing friction. They are also used in wing flap actuators, where their lightweight and wear-resistant properties ensure reliable performance.

Silicon Nitride Balls are used in defense equipment that needs high durability and thermal stability. Their ability to resist wear and withstand extreme temperatures makes them perfect for military machinery and weapons systems. This ensures reliable performance in tough conditions.

Silicon Nitride Balls help electric vehicle motors by preventing arcing and improving efficiency. Their electrical insulating properties stop unwanted currents. This reduces wear on the motor. As a result, the motor runs smoothly, boosting performance and lifespan.

Silicon Nitride Balls are important in autonomous vehicles for smooth operation of electric motor shafts. Their low friction and wear resistance make them ideal for electric motors. They also have high thermal stability. This improves efficiency and reliability in autonomous systems.

Wind turbine generators benefit from Silicon Nitride’s high load-bearing capacity and durability. This is especially important for large-scale applications. The material can withstand heavy loads and resist wear under continuous stress. It helps critical components, like bearings, operate smoothly.

Silicon Nitride also resists heat and corrosion. This allows wind turbines to perform efficiently in harsh conditions. It reduces maintenance needs and increases the equipment’s lifespan.

Silicon Nitride’s durability and wear resistance lead to low maintenance requirements for wind turbines. With fewer repairs and replacements needed, the overall lifecycle costs are reduced. This makes wind turbines more cost-effective, as they can operate longer with less downtime.

Silicon Nitride Balls are used in semiconductor manufacturing. They work well in high-speed, low-lubrication environments. Their low friction and wear resistance help them run efficiently with little lubrication.

This is important in cleanrooms where contamination must be avoided. They are durable, which means less maintenance and smooth operation.

Silicon Nitride Balls can extend bearing life by 50% or more compared to steel. Their high wear resistance and durability reduce the need for frequent replacements. This makes them more cost-effective and reliable over time.

Silicon Nitride Balls are used in bicycle wheel hubs to reduce friction, lower weight, and extend bearing life. These benefits contribute to smoother, faster cycling performance by improving efficiency and reducing the need for frequent maintenance. The lighter weight of the balls also helps enhance the overall performance of the bicycle.

|

Property |

Silicon Nitride |

Steel |

|

Hardness |

Twice as hard as steel |

Lower hardness compared to silicon nitride |

|

Wear Resistance |

Excellent wear resistance |

Good, but less resistant than silicon nitride |

|

Thermal Resistance |

High thermal resistance (up to 1800°F/980°C) |

Lower thermal resistance, prone to thermal deformation at high temperatures |

Silicon Nitride offers superior performance under high speed and high temperature. It has exceptional hardness, wear resistance, and can withstand temperatures up to 1800°F (980°C). This makes it ideal for demanding applications, like high-speed machinery, aerospace, and automotive systems. It provides longer-lasting, more efficient performance compared to steel, which struggles in extreme conditions.

Silicon Nitride has excellent corrosion resistance. This makes it ideal for harsh environments. Also non-conductive, it prevents electrical currents from passing through.

These properties protect electric motors from corrosion and electrical damage. As a result, they ensure reliable performance.

Steel has challenges in harsh environments. Being prone to corrosion, it is susceptible to rusting. Steel is also magnetic, which can interfere with sensitive electronics, like in electric motors. These issues make steel less ideal for some high-performance applications compared to Silicon Nitride.

The initial cost of Silicon Nitride Balls is higher than that of steel balls. However, their longer lifespan, lower maintenance costs, and superior performance in demanding applications make them a better overall value.

Silicon Nitride Balls reduce the need for frequent replacements and offer better efficiency. This leads to lower downtime and maintenance costs in the long run. In high-performance or harsh environments, the higher upfront cost is often a consideration. However, it is outweighed by long-term savings and improved reliability.

Silicon Nitride Balls are ideal for precision applications because they are hard, wear-resistant, and have low friction. They can handle high temperatures, are non-magnetic, and don’t conduct electricity. These qualities make Silicon Nitride Balls durable and reliable. They are perfect for use in tough environments like aerospace, medical devices, and high-speed machinery.

Silicon Nitride Balls are used in many industries like aerospace and medical devices. They have a longer service life, reducing the need for frequent replacements. They also reduce the need for re-lubrication, as they run efficiently for longer periods. This means higher efficiency and lower maintenance costs in demanding applications.

Silicon Nitride Balls are hard, wear-resistant, and have low friction. They can handle high temperatures, making them perfect for precision bearings. These balls are used in industries like aerospace, medical devices, and electric motors. They last longer, need less maintenance, and improve efficiency.

If you need high performance and reliability, consider Silicon Nitride Balls. They are highly durable, exhibit low friction, and are capable of withstanding demanding conditions. Perfect for industries like aerospace and medical devices, they improve performance and lower long-term costs.

Bearings play a crucial role in numerous applications, reducing friction and enabling smooth, efficient operations. Among the wide range of bearing...

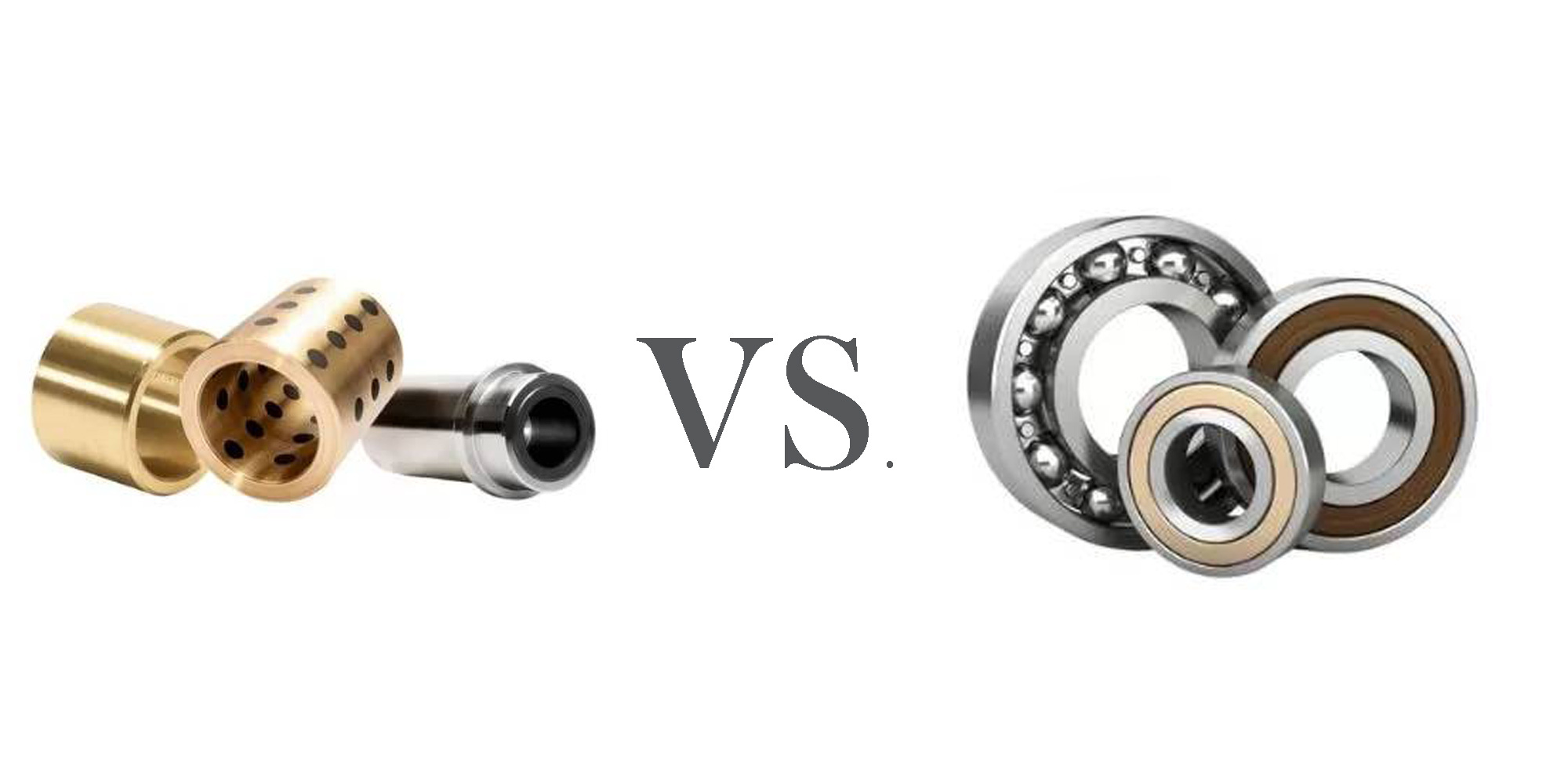

In the world of machinery and mechanical engineering, bearings and bushings are two essential components that are used to support and guide moving...

Effective bearing measurement is key for optimal machine performance and safety. It helps identify the right bearing type and size, especially when a...