What Is the Difference between a Radial Ball Bearing and a Thrust Ball Bearing?

In the world of machinery, ball bearings play a pivotal role. They reduce friction and ensure smooth operation of various mechanical systems. But did...

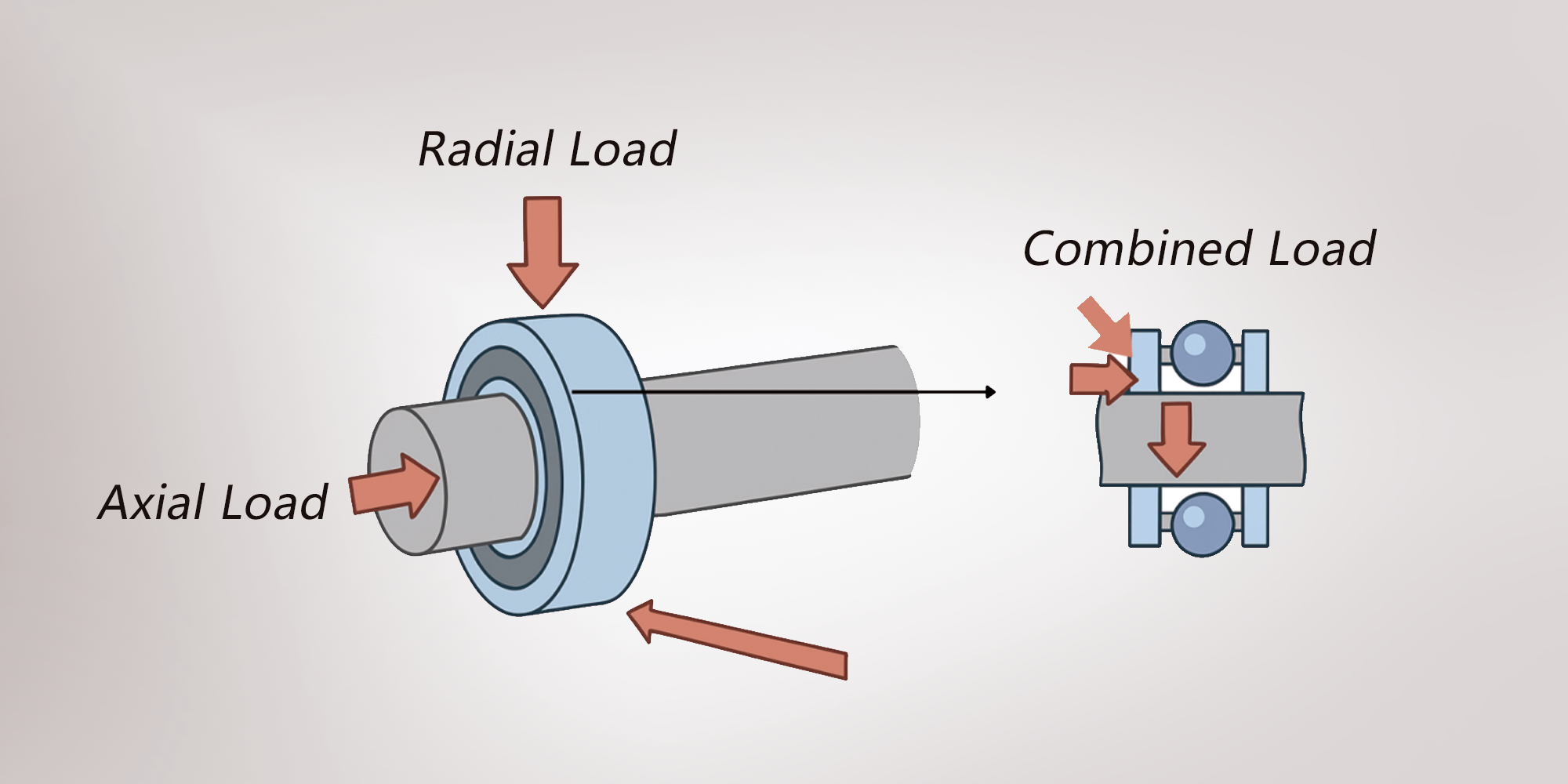

Radial and axial loads apply force in different directions, and using the wrong bearing type can lead to premature wear, system inefficiencies, or failure.

Understanding these fundamental forces is key to selecting the right bearings, improving system performance, and extending component lifespan.

Whether you're troubleshooting failure points or optimizing custom bearing designs, this article will help unravel the complexities of bearing loads so you can make informed decisions.

Radial load is one of the most common and one of the two primary force directions that bearings must accommodate, the other being axial load.

Selecting the correct bearing type and accommodating radial forces is essential for maintaining performance, reducing wear, and ensuring system durability.

Radial load is a type of centrifugal force acting perpendicularly to the axis of a rotating shaft or component, directed towards its center.

In bearings, it's the load carried at right angles to the rotation axis.

Radial loads are typical in rotating applications such as car wheels, machine shafts, electric motors, pulleys, and gearboxes.

For example, a car's wheel bearings experience varying radial loads dependent on the vehicle's speed and weight.

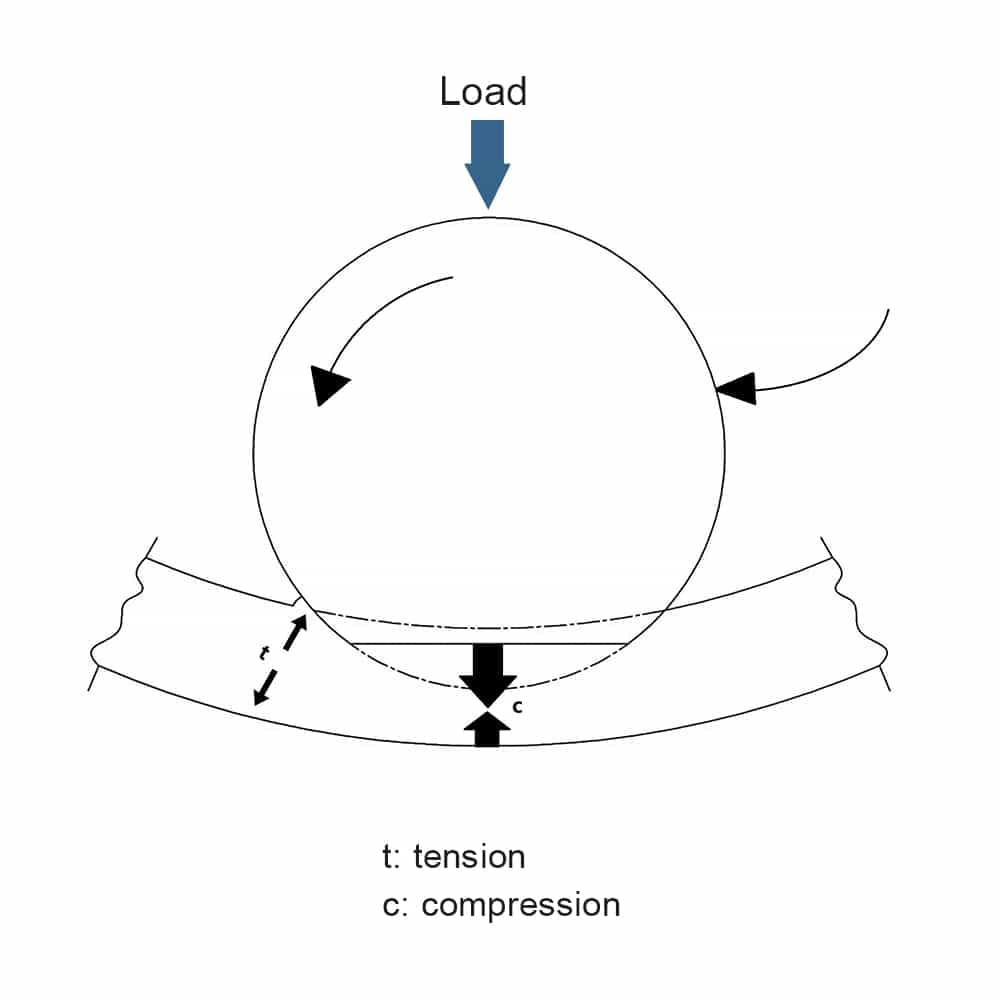

In a bearing subjected to radial load, the load is transferred from the inner raceway through the rolling elements (balls or rollers) to the outer raceway.

The force is distributed over several rolling elements simultaneously, depending on the bearing design and the size of the load.

Radial load distribution impacts bearing performance and longevity.

Proper distribution prevents over-stressing individual elements, ensuring balanced wear.

However, uneven distribution can cause premature bearing failure due to excessive stress on certain elements.

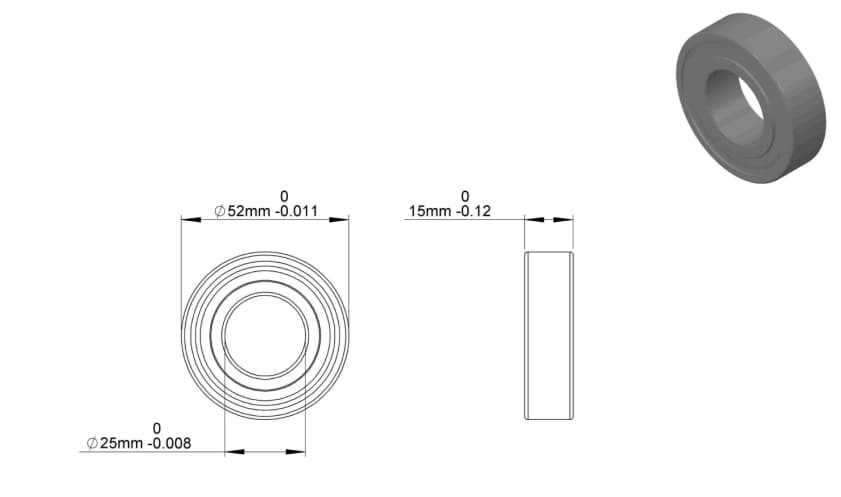

Various bearings handle radial loads, including deep groove ball bearings for their versatility, cylindrical roller bearings and needle roller bearings for heavy loads, and self-aligning ball bearings for misalignment scenarios.

Each type is selected based on the application and load magnitude.

Unlike radial loads that push perpendicular to the shaft, axial loads push or pull in line with the shaft’s centerline.

These forces are crucial to consider when designing components that experience significant end-to-end pressure, as choosing the wrong bearing for axial forces can lead to decreased efficiency, faster wear, or premature failure.

Axial load, synonymous with thrust or parallel load, is the force that acts parallel to the shaft's axis.

Simply put, it's a force that's exerted along the lines of the center, or axis, of an object.

Axial loads are prevalent in various sectors, including automotive axles, aerospace jet engines, wind turbines, and industrial conveyor systems.

They also occur in pumps and compressors, and screw drive systems due to forces exerted by fluid, gas, or mechanical movement.

Axial load transfers through a bearing's raceways and rolling elements.

In thrust ball bearings, the load passes from one washer to another via balls aligned parallel to the rotation axis, enabling high axial load capacity.

Tapered roller bearings handle axial and radial loads, with their tapered design facilitating axial load transfer along inclined surfaces, thereby improving load distribution and reducing stress.

Achieving balanced load distribution in axial load scenarios is key for optimal bearing performance, durability, and smooth operation.

Ideally, axial loads are equally shared among all rolling elements, minimizing wear and enhancing bearing efficiency.

Factors such as misalignment or uneven loading can disrupt this balance, increasing stress and potentially leadinng to premature failure.

Thrust bearings are the go-to choice for handling axial loads due to their design that accommodates forces parallel to the axis.

Types include thrust ball bearings for lighter loads and thrust roller bearings for heavier loads.

Angular contact ball bearings can manage combined radial and axial loads, provided the axial component is significant.

Differentiating between radial and axial loads, or understanding the concept of radial vs axial load, is vital for the optimal selection and use of bearings.

The primary distinctions lie in the direction of the force applied - radial loads act perpendicular to the shaft's axis, and axial loads act parallel to it.

The type of bearing used also varies between these loads.

While deep-groove ball bearings are better equipped to handle radial loads, thrust ball bearings are designed for axial loads.

However, it's essential to note that most bearings, such as angular contact ball bearings, can handle both radial and axial loads.

For a more comprehensive understanding, let's look at a comparative table:

| Radial Load | Axial Load | |

| Force Direction | Perpendicular to the shaft's axis | Parallel to the shaft's axis |

| Load Distribution | Distributes force across the circumference of the bearing, | Distributes force along the bearing's axis |

| Bearing Examples | Deep-groove ball bearings, cylindrical roller bearings, needle roller bearings | Thrust ball bearings, tapered roller bearings |

| Typical Applications | Rotating Machinery, Wheels, Conveyor belts, electric motors, gearboxes, etc. | Vertical shafts in transmissions, helicopters, Wind Turbines, etc. |

In most situations, bearings aren’t subjected to just radial or just axial forces, but rather a combination of both (sometimes, moment loads as well).

These combined loads require bearings that can handle forces from multiple axial directions at the same time, so careful selection, load calculations, and engineering are needed.

Angular contact ball bearings and tapered roller bearings are examples of bearings designed to handle dual forces.

Understanding combined loads is key in applications like automotive wheel hubs, industrial gearboxes, and turbines, where unbalanced or mis-calculated forces can cause premature wear and failure.

There are also non-roller style bearings (i.e., telescopic rails) with individual balls that move along their surface.

These are most commonly used for cabinet drawers and machinery that extends and retracts loads during operation.

The type of load (i.e., radial, axial, or a combination) determines which bearing is best for a given application.

Bearings are engineered for specific load directions and capacities, so selecting the wrong one can result in reduced performance or failure.

For example, deep groove ball bearings handle mostly radial loads but can handle some axial loads, while angular contact bearings are for applications where both radial and axial loads are high.

Matching load to bearing design is critical for system reliability, safety, and longevity.

Assessing radial and axial loads in real-world applications demands attention to various aspects such as operating speed, load magnitude and direction, and the operating environment.

Carefully balancing these loads can lead to a noticeable improvement in bearing performance and life.

A case study worth mentioning is in the realm of automotive wheel bearings.

These bearings need to handle both radial loads (from the vehicle's weight) and axial loads (from cornering forces).

The delicate balance and distribution of these loads are crucial for the smooth and efficient operation of the vehicle.

Additionally, the bearing's material selection, like Chrome Steel or Stainless Steel, also plays a significant role in handling radial and axial loads.

Chrome Steel, for instance, is often used for its high load capacity and wear resistance, making it suitable for applications with high radial and axial loads.

Understanding and managing radial vs axial load can greatly enhance bearing performance and longevity.

Selecting the right bearing, based on the load nature, can boost your machinery's efficiency.

At LILY Bearing, we provide a wide range of bearings to meet varied load needs.

Our expertise and quality commitment assure optimal performance and extended machinery life through our tailored bearing solutions.

Explore our full selection of bearings designed for radial, axial, or combined load support.

In the world of machinery, ball bearings play a pivotal role. They reduce friction and ensure smooth operation of various mechanical systems. But did...

Understanding bearing axial load, just like understanding different types of bearing load, is crucial for ensuring the proper functioning and...

Thrust bearings play a pivotal role in the industrial sector, managing axial loads while ensuring efficient, smooth operation across diverse...