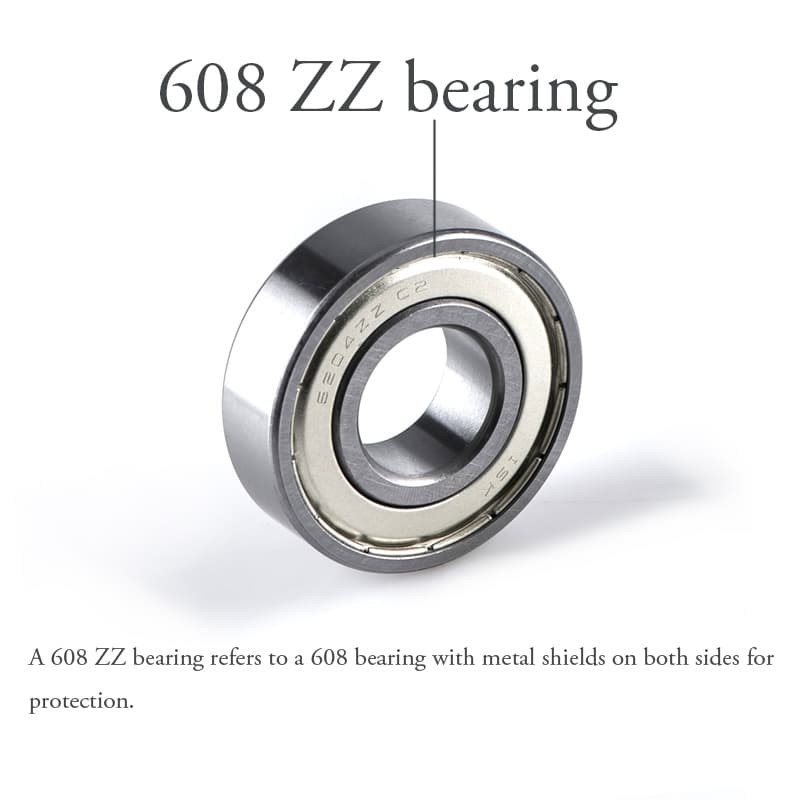

Single Row VS Double Row Ball Bearings

Ball bearings reduce friction between moving parts. This allows smooth movement and supports both radial and axial loads. They have balls between two...

Industrial rollers are the unsung heroes of manufacturing and various other sectors, playing a pivotal role in ensuring smooth operations, precise product handling, and optimal machinery performance. As we delve into the landscape of roller materials, two names consistently emerge at the forefront: Polyurethane and Rubber. In our exploration of Polyurethane Vs Rubber Rollers, we aim to provide a comprehensive comparison, shedding light on the distinct features, benefits, and potential drawbacks of each, thus empowering businesses to make informed decisions tailored to their specific needs.

Polyurethane and Rubber share certain essential traits that have made them popular choices across industries. Some of their shared characteristics include:

Abrasion Resista nce: Polyurethane rollers are designed to provide top-notch performance even under conditions of intense friction and significant load -bearing, marking them as superior in environments where wear and tear are common.

Read “Polyurethane Rollers: Advantages & Uses”for further understanding.

Natural Elasticity: Rubber rollers are renowned for their inherent elastic properties. This elasticity makes them pliable and adaptable, suitable for a plethora of applications across various industries.

To simplify the understanding of the core differences and similarities between polyurethane and rubber rollers, here's a side-by-side comparison table. It sheds light on their attributes, offering a quick yet comprehensive reference:

|

Attribute |

Polyurethane Rollers |

Rubber Rollers |

|

Elasticity |

Superior in certain formulations, adaptable to varying hardness. |

Inherently elastic, suitable for many applications. |

|

Abrasion Resistance |

Highly resistant, especially under heavy loads and high friction. |

Less resistant compared to polyurethane. |

|

Wet Environment Suitability |

Resistant to degradation, even when submerged or exposed to moisture. |

Vulnerable to rotting or degrading in damp conditions. |

|

Chemical Composition |

Offers room for custom formulations, adapting to specific needs. |

Might be altered with specific fillers, but sensitive to certain chemicals. |

|

Propensity to Leave Marks |

Non-marking property ensures minimal product contamination. |

Has a propensity to leave marks, especially on delicate items. |

|

Manufacturing & Industrial Use |

Versatile and widely used in various manufacturing processes. |

Long-standing history in numerous industries. |

|

Environmental Impact |

Depending on the formulation, some types might be more eco-friendly. |

Generally, has a larger environmental footprint, especially if not recycled. |

|

Cost |

Often a higher initial investment than rubber. |

Typically less expensive initially but may incur costs in the long run due to durability issues. |

In evaluating Polyurethane Vs Rubber Rollers, both materials present unique advantages. Polyurethane excels in abrasion resistance and versatility, while rubber boasts inherent elasticity. When choosing, consider your specific operational needs to determine the optimal solution. This analysis aims to guide your informed decision between these two prominent roller materials.

Have you had experiences using either Polyurethane or Rubber Rollers in your industry? Share your thoughts in the comments below!

Ball bearings reduce friction between moving parts. This allows smooth movement and supports both radial and axial loads. They have balls between two...

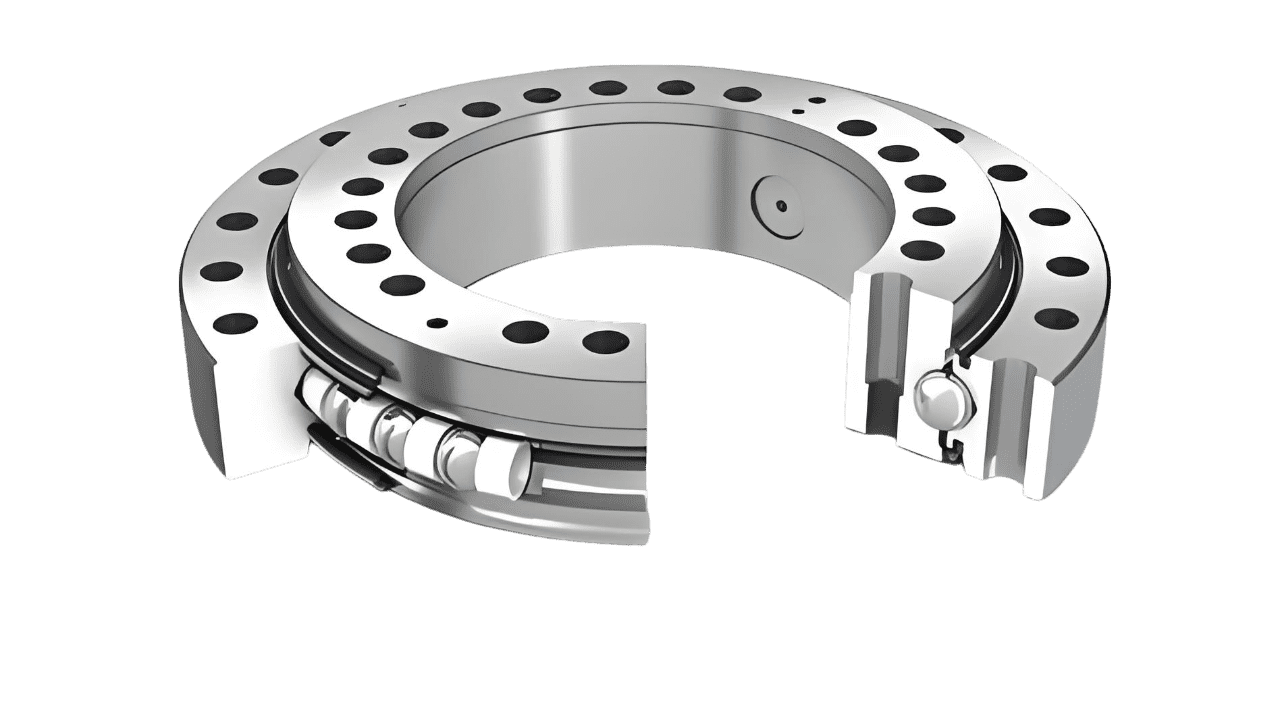

In the world of machinery, the choice of bearings can greatly impact performance. Cross roller bearings, a specific type of roller bearings, offer...

In the intricate realm of aerospace, ball bearings serve a pivotal role, ensuring precision, efficiency, and durability in various mechanical...