Polyurethane Rollers: Advantages & Uses

In the modern industrial world, polyurethane rollers are key players. They help many processes run smoothly and efficiently, proving to be both...

Polyurethane rollers with bearings are crucial for enhancing machinery efficiency and performance. They provide durability, low friction, and high load-bearing capacity, reducing wear and tear while ensuring smooth operation. This blog will explore the features and uses of polyurethane rollers with bearings. We also dig into benefits, applications, and how to choose the right solution for your needs.

Polyurethane rollers with bearings are industrial components that integrate urethane materials with bearings. This combination provides superior load-bearing capacity, durability, and smooth operation. Urethane's resistant to abrasion, impact, and chemicals, coupled with the low friction and precision of bearings. This makes these rollers ideal for enhancing efficiency and performance in various applications, such as material handling, assembly lines, and manufacturing processes.

Polyurethane is perfect for rollers in harsh conditions. This happens because it bounces back after someone squishes or bends it. It also resist chemicals, so it doesn't break down when it comes into contact with oils or solvents.

Its impact resistance ensures durability and longevity, making polyurethane rollers highly effective for industrial applications where performance and longevity are crucial.

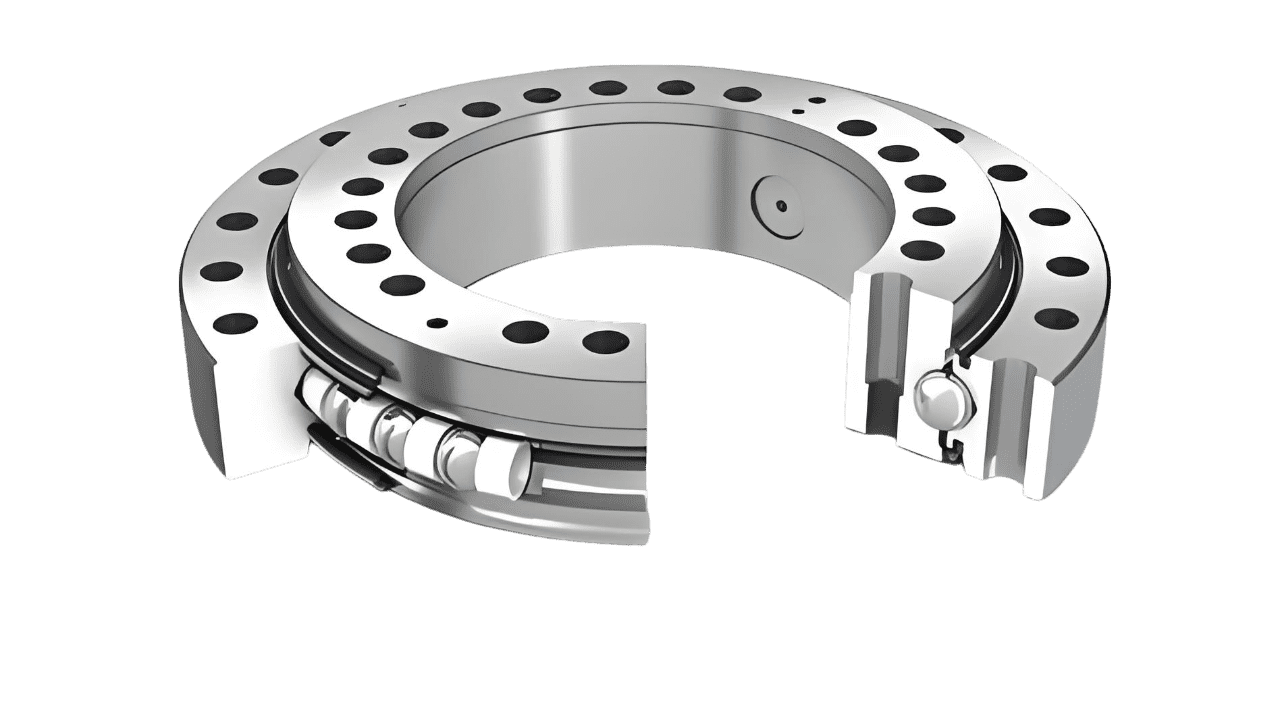

Polyurethane rollers can be integrated with various types of bearings, each contributing to smooth rotation and reduced friction.

Polyurethane rollers with bearings can be customized extensively to suit specific application needs:

Polyurethane rollers with bearings enhance load bearing capacity by effectively distributing loads across the roller surface.

High-performance bearings including ball bearings, needle bearings, and tapered roller bearings can boost the load-bearing capacity. They also enhances the overall efficiency and durability of the rollers.

The internal bearings reduce friction and wear. They allow the rollers to handle heavier loads than conventional rollers without compromising performance or durability.

The combination of polyurethane and bearings in rollers significantly improves wear resistance. Polyurethane's inherent durability and resistance to abrasion allow the rollers to withstand long-term friction without damage.

Bearings play a crucial role in enhancing the performance and longevity of polyurethane rollers. By reducing friction and evenly distributing loads, they minimize wear on both the rollers and the machinery. This leads to a longer service life for the rollers, which significantly reduces maintenance costs. With fewer replacements and repairs needed, the overall efficiency and reliability of the machinery improve greatly.

Integrated bearings ensure smooth movement with minimal friction, improving operating efficiency in various applications. Polyurethane wheels are designed to provide consistent performance even under heavy-duty conditions.

Urethane rollers with bearings play a role in conveyors and rollers. They guides to ensure smooth, efficient transportation of materials in industries like warehousing, logistics, and automotive manufacturing. They also provide floor protection by reducing surface wear and tear.

Polyurethane rollers with bearings are used in gearboxes, wheel hubs and axles. They drive systems where high load-bearing capacity and smooth rotation are critical.

These rollers are ideal for packaging machines, sorting systems, and production lines in food processing and packaging industry. These applications require hygiene, durability, and high performance.

For textile and paper industries, polyurethane rollers with bearings play a role in processes like spooling, winding, and cutting. They require resistance to abrasion and tight tolerances.

To match roller and bearing types with specific load capacity and speed requirements, consider the following:

To choose the appropriate polyurethane material and hardness based on the operating environment:

Selecting the right bearing type and mounting style is essential for optimal roller performance:

Regular inspections of polyurethane rollers help detect wear, misalignment, and lubrication issues early, preventing breakdowns and extending the roller's lifespan. Proper inspections ensure smooth operation, reduce maintenance costs, and maximize equipment efficiency.

For polyurethane rollers with bearings, use grease for its long-lasting lubrication and oil mist for high-speed applications. Ensure lubricant compatible with materials and components. Apply evenly and maintain regularly to reduce friction and extend roller life.

Watch for signs of wear, like noise, vibration, or color changes due because of heat. This can keep polyurethane rollers with bearings in good condition without spending too much.

Replace bearings using correct tools and techniques, ensuring new bearings match specifications.

Regular inspections and timely replacements, along with proper lubrication, extend roller life and reduce maintenance costs.

Polyurethane rollers with bearings offer numerous benefits for industrial applications. They are highly durable and can handle heavy loads, making them ideal for manufacturing, material handling, and assembly lines. Their wide range of applications allows tailoring to meet specific needs, ensuring optimal performance in various environments.

For expert guidance in selecting the right high quality polyurethane roller and bearing for your application, contact LILY Bearing. They provide tailored solutions to enhance efficiency and reliability in your operations.

In the modern industrial world, polyurethane rollers are key players. They help many processes run smoothly and efficiently, proving to be both...

In industrial settings, rollers are key to keeping machinery and processes running smoothly. Polythane and rubber are the top materials used for...

Industrial rollers are the unsung heroes of manufacturing and various other sectors, playing a pivotal role in ensuring smooth operations, precise...