Characteristics, Uses and Advantages of Stainless Steel Bearings

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...

Grasp the intricacies of McGill part numbers for tailored bearing choices. Since the CAMROL® patent in 1905, McGill has expanded to over 1,400 bearing configurations. This guide sheds light on picking the right bearings, delving into their rich history, diverse options, and performance tips.

The structure of McGill Bearings part numbers consists of a prefix, suffix, and designation. Together provide detailed specifications for each bearing.

The prefix typically indicates the bearing series or type. The suffix provides additional information such as the material or special features like sealing. The designation encompasses details like size, dimensions, and design specifics.

Here's a high-level diagram to illustrate the structure:

Prefix + Suffix + Designation

[Series/Type] + [Material/Features] + [Size/Dimensions/Design]

This structure allows for a systematic and detailed identification of bearing specifications. It ensures that you select correct bearing for any given application.

|

Prefix |

Meaning |

|

.0 |

SPHERE-ROL, indicates standard diametral clearance |

|

.10 |

CAGEROL, retainer not penetrate treated |

|

.100 |

CAGEROL, split into two halves |

|

.20 |

MULTIROL, new design, spring steel rings replace rolled lips |

|

.30 |

MULTIROL, MI inners, old style large diameter race |

|

.9 |

CAMROL, indicates close running clearance between outer ring counter-bore and flange O.D. (0.003 inch) |

|

.A |

CAMROL, CAM FOLLOWER, radial oil hole omitted in stein or plugged, or SPHERE-ROL with tapered bore plus adapter sleeve, locknut, and lockwasher |

|

.C |

STANDARD BEARING, all external surfaces chrome plated |

|

.C2 |

SPHERE-ROL, indicates diametral clearance less than standard |

|

.C3 |

SPHERE-ROL, indicates diametral clearance larger than standard |

|

.C4 |

SPHERE-ROL, indicates diametral clearance larger than C3 |

|

.CR |

STAINLESS STEEL (CORROSION-RESISTING) |

Prefixes in McGill Bearings part numbers provide key specs:

|

Obsolete Prefix |

Equivalent Prefix |

Description |

|

.DB |

R |

Obsolete prefix for radial fitting Gurney type bearings, now replaced by "R" for paired bearings duplex mounted back-to-back |

|

.DF |

U |

Obsolete prefix for a specific type of bearing, now replaced by "U" for duplex mounted, face-to-face bearings |

The table below explains when and why certain prefixes became obsolete.

|

No. |

When Prefixes Become Obsolete |

Why Prefixes Become Obsolete |

Example |

|

1 |

Technological Advancements |

Product Improvements |

Older bearings are replaced with new designs for better performance. |

|

2 |

Changes in Industry Standards |

Cost Reduction |

Bearings no longer meeting updated standards are phased out to reduce production costs. |

|

3 |

Market Dynamics |

Customer Feedback |

Discontinued due to low demand based on customer preferences. |

|

4 |

Production Efficiency |

Environmental Concerns |

Streamlining production leads to the obsolescence of certain bearing types. |

|

5 |

Regulatory Changes |

Safety and Compliance |

Products are redesigned or discontinued to meet new safety regulations. |

|

Suffix |

Meaning |

|

.A |

1. CAMROL, CAM FOLLOWER, RADIAL OIL HOLE OMITTED IN STEIN OR PLUGGED 2. SPHERE-ROL, WITH TAPERED BORE PLUS ADAPTER SLEEVE, LOCKNUT AND LOCKWASHER |

|

.AL |

ALUMINUM ALLOY RETAINER OR SEPARATOR |

|

.B |

CAMROL, CAM FOLLOWER, HEXAGONAL HOLE REPLACES SCREWDRIVER SLOT IN FLANGE END OF STEM |

|

.C |

STANDARD BEARING, ALL EXTERNAL SURFACES CHROME PLATED |

|

.C2 |

SPHERE-ROL, INDICATES DIAMETRAL CLEARANCE LESS THAN STANDARD |

|

.C3 |

SPHERE-ROL, INDICATES DIAMETRAL CLEARANCE LARGER THAN STANDARD |

|

.C4 |

SPHERE-ROL, INDICATES DIAMETRAL CLEARANCE LARGER THAN C3 |

|

.CL |

SPHERE-ROL, INDICATES DIAMETRAL CLEARANCE LESS THAN C2 |

|

.CP |

STANDARD BEARING WITH CHROME PLATED O.D., ALL OTHER EXPOSED SURFACES, AS MOUNTED, CADMIUM PLATED |

|

.CR |

STAINLESS STEEL (CORROSION-RESISTING) |

|

.CU |

COPPER ALLOY RETAINER OR SEPARATOR |

|

Suffix |

Description |

|

.A |

CAMROL: Radial oil hole omitted or plugged. |

|

.AL |

Aluminum alloy retainer or separator. |

|

.B |

CAMROL with hexagonal hole replacing screwdriver slot in flange end of stem. |

|

Suffix |

Description |

|

+E |

CAMROL, CAM FOLLOWER, ECCENTRIC BUSHING PRESSED ON STEM |

|

+L |

CAMROL, WITH LUBRI-DISC FEATURE |

|

AN |

SPHERE-ROL, LARGE LOCKNUT (SEE "N" PREFIX) |

|

ASMO |

MULTIROL, SINGLE-ROW, OUTER RACE AND ROLLER ASSEMBLY, SELF-ALIGNING, SPHERICAL HOUSING AND O.D. |

|

B |

BALL BEARING FOR PILLOW BLOCK (MFG. FOR BROWNING) |

|

BA |

ANNULAR BALL BEARING, SINGLE-ROW, COUNTERBORED OUTER RING, ANGULAR CONTACT, CONTACT ANGLE 22 DEGREES TO 32 DEGREES |

|

BB |

SPECIAL BALL BEARINGS |

|

BC |

ANNULAR BALL BEARING, SINGLE-ROW, RADIAL, NON-LOADING GROOVE SELF-CONTAINED |

|

BH |

ANNULAR BALL BEARING, SINGLE-ROW, COUNTERBORED OUTER RING, RADIAL |

|

BM |

BALL BEARING FOR PILLOW BLOCK (MFG. FOR T.B. WOOD) |

|

BN |

ANNULAR BALL BEARING, SINGLE-ROW, COUNTERBORED OUTER RING, ANGULAR CONTACT, CONTACT ANGLE 10 DEGREES TO 22 DEGREES |

|

BR |

SPECIAL ROLLER BEARING |

|

BT |

ANNULAR BALL BEARING, SINGLE-ROW, COUNTERBORED OUTER RING, ANGULAR CON-TACT, CONTACT ANGLE 32 DEGREES TO 45 DEGREES |

|

CF |

CAMROL, CAM FOLLOWER, FULL COMPLIMENT ROLLER BEARING, WITH INTEGRAL STUD |

|

CFH |

CAMROL, CAM FOLLOWER, FULL COMPLIMENT ROLLER BEARING WITH INTEGRAL HIGH CAPACITY STUD |

|

CT |

SPECIAL ROLLER BEARING UTILIZING CENTER GUIDED ROLLER ASSEMBLY |

|

CYR |

CAMROL, YOKE ROLLER, FULL COMPLIMENT ROLLER BEARING WITH INNER RACE FOR YOKE MOUNTING |

|

EMRF |

CAGEROL, CAM FOLLOWER, HEAVY SECTION OUTER WITH INNER RING |

|

F+ |

PILLOW BLOCK SERIES, INDICATES 4-BOLT BASE ON SIZES NOT ALREADY HAVING THAT FEATURE |

|

GR |

GUIDEROL, HEAVY DUTY ROLLER BEARING, SELF-CONTAINED, OUTER RACE AND CENTER GUIDED ROLLER ASSEMBLY |

|

GRI |

GUIDEROL, WITH SEPARABLE INNER RACE. METRIC SIZES. |

|

GTR |

DRAWN CUP ROLLER BEARING, WITH ONE PIECE RETAINER, SINGLE-ROW OR ROLLERS, NO INNER, OPEN ENDS, PRECISION GROUND O.D. REGULAR ROLLER SERIES. |

|

Suffix |

Function/Application Category |

Description |

|

+E |

Adjustment Feature |

CAMROL cam follower with an eccentric bushing for radial clearance adjustment. |

|

AN |

Locking Mechanism |

SPHERE-ROL bearing with a large locknut for secure installation (details in "N" prefix). |

The Bearing Block Part Number System enhances the overall bearing system. They offer a straightforward way to identify specific features of the block. These include the material used, the bolt pattern, and the size of the bearing insert.

This integration ensures seamless selection of both bearings and their housings, maintaining consistency and efficiency in inventory and application.

Example 1: FP2-10-1

This part number clearly specifies a flange-style bearing block made of stamped steel with a 2-bolt mounting arrangement. And it is suitable for a low-cost, non-reloadable ball bearing with a one-inch bore diameter.

Example 2: PFC4-25-1 1/4-S

Example 3: NDLW-25-1-9/16

Example 4: DD-35-1-1/2

The chart below is a quick reference. You can check it to figure out what the different suffixes in McGill Bearings part numbers actually mean.

|

Suffix |

Meaning |

|

.C2 |

SPHERE-ROL with diametral clearance less than standard |

|

.CR |

Bearing made of stainless steel, resistant to corrosion |

|

.T |

Axial lubrication hole (CAMROL) or paired face-to-face mounting or steel cage with Tufftrida treatment. |

|

.DT |

Obsolete; refer to the ".T" suffix for equivalent specifications |

The table below serves as a quick reference. It helps you to the prefixes and suffixes in McGill Bearings part numbers.

| Prefix | Description |

|---|---|

| CAMROL | Indicates a cam follower bearing with a cylindrical or tapered bore. |

| TRAKROL | Indicates a cam follower bearing with a precision needle roller insert. |

| CAGEROL | Indicates a needle roller bearing with a cage. |

| SPHERE-ROL | Indicates a spherical roller bearing. |

| GUIDEROL | Indicates a guide roller bearing. |

| MULTIROL | Indicates a multi-roller bearing. |

| MCYRD | Indicates a metric-sized cam follower bearing. |

| Suffix | Description |

|---|---|

| 0 | Standard radial clearance for SPHERE-ROL bearings. |

| 10 | Standard cage design for CAGEROL bearings. |

| 100 | Split cage design for CAGEROL bearings. |

| 20 | New design with a spring steel ring instead of a crimped edge (MULTIROL). |

| 30 | Old design with a larger diameter inner ring (MULTIROL). |

| 9 | Smaller radial clearance between outer ring and flange (CAMROL). |

| A | No radial oil hole (CAMROL) or tapered bore with adapter, locknut, and lockwasher (SPHERE-ROL). |

| AL | Aluminum alloy cage or separator. |

| B | Hexagonal hole in flange instead of a screwdriver slot (CAMROL). |

| C | All external surfaces chrome-plated (standard bearing). |

| C2 | Radial clearance less than standard (SPHERE-ROL). |

| C3 | Radial clearance greater than standard (SPHERE-ROL). |

| C4 | Radial clearance greater than C3 (SPHERE-ROL). |

| CL | Radial clearance less than C2 (SPHERE-ROL). |

| CP | Outer ring chrome-plated, other exposed surfaces cadmium-plated (standard bearing). |

| CR | Stainless steel (corrosion-resistant). |

| CU | Copper alloy cage or separator. |

| D | Precision matched needle roller bearing in sets (number indicates set quantity). |

| DB | Obsolete, see “R”. |

| DF | Obsolete, see “U”. |

| DO | General-purpose double-row bearing. |

| E | End clearance for shaft expansion (SPHERE-ROL). |

| F | Lubrication hole in outer ring (airframe bearing) or single-side seal (obsolete). |

| FF | Double-side seal (obsolete). |

| FFG | Double-side seal with outer ring groove and snap ring (obsolete). |

| FG | Single-side seal with snap ring and groove (obsolete). |

| FG-1 | Single-side seal with snap ring and groove on the same side as the seal (obsolete). |

| G | Outer ring groove and snap ring (obsolete) or larger outer diameter of inner ring (number indicates increment). |

| GH | Hooked snap ring and outer ring groove (obsolete). |

| GO | Outer ring groove only (obsolete). |

| J | Outer ring and corner chrome-plated, other exposed surfaces cadmium-plated (airframe bearing). |

| K | Tapered bore (1:12) for SPHERE-ROL bearings. |

| KE | Tapered bore with expansion characteristics (SPHERE-ROL). |

| KM | K-Monel metal. |

| LH | Left-hand thread (CAMROL). |

| M | Maximum load capacity or loading slot type ball bearing. |

| N | Narrow type. |

| NS | Non-separable (self-contained) bearing. |

| P | All external surfaces cadmium-plated (standard bearing) or exposed surfaces cadmium-plated (airframe bearing). |

| PC | Synthetic cage or separator. |

| PEN | Black oxide finish. |

| PT | Synthetic tire mounted on outer ring diameter. |

| R | Radially assembled Gurney type bearing (obsolete) or paired back-to-back mounting. |

| RS | Single-side seal (lip facing outward) for CAGEROL or GUIDEROL bearings. |

| RSS | Double-side seal (lip facing outward) for CAGEROL or GUIDEROL bearings. |

| S | Special design or tolerance range bearing. |

| SL | Sealed, with tapered bore only on the large hole side (SPHERE-ROL). |

| SR | Pillow block series, stabilizing ring (part of pillow block assembly). |

| SRS | Double-side seal (one lip facing inward, one facing outward) for CAGEROL or GUIDEROL bearings. |

| SS | Double-side seal (lip facing inward) for CAGEROL or GUIDEROL bearings or double-side sealed SPHERE-ROL bearings. |

| T | Axial lubrication hole (CAMROL) or paired face-to-face mounting or steel cage with Tufftrida treatment. |

| U | Paired face-to-face mounting. |

| UNA | Unassembled bearing, including all components. |

| W | Wide type. |

| W/O | Without standard components (e.g., seals). |

| W20 | Lubrication hole in outer ring diameter (SPHERE-ROL). |

| W22 | Outer ring diameter size selected (SPHERE-ROL). |

| Y | Inner ring with annular lubrication groove and hole (airframe bearing). |

| Z | Outer ring with annular lubrication groove and hole (airframe bearing). |

| +E | Eccentric sleeve pressed onto shaft (CAMROL). |

| +L | Lubri-Disc feature (CAMROL). |

| AN | Large locknut (see “N” prefix) for SPHERE-ROL. |

| ASMO | Self-aligning, single-row, outer ring and roller assembly with spherical outer diameter (MULTIROL). |

| B | Pillow block ball bearing (manufactured for Browning). |

| BA | Single-row angular contact ball bearing with chamfered outer ring, contact angle 22° to 32°. |

| BB | Special ball bearing. |

| BC | Single-row radial ball bearing with chamfered outer ring, non-loading slot type. |

| BH | Single-row radial ball bearing with chamfered outer ring. |

| BM | Pillow block ball bearing (manufactured for T.B. Wood). |

| BN | Single-row angular contact ball bearing with chamfered outer ring, contact angle 10° to 22°. |

| BT | Single-row angular contact ball bearing with chamfered outer ring, contact angle 32° to 45°. |

| C+ | Outer ring with crowned radius (CAMROL). |

| CF | Full complement roller bearing with integral shaft (CAMROL). |

| RN | Cylindrical roller bearing with two-lip inner ring, cylindrical outer ring, rollers, and cage, separable outer ring. |

| RP | Two-piece cage, single-row, stamped. |

| RS | Self-contained, single-row, outer ring and roller assembly (MULTIROL) or aviation type (CAMROL). |

| RT | Aviation type (CAMROL). |

| RU | Cylindrical roller bearing with two-lip outer ring, cylindrical inner ring, rollers, and cage, separable inner ring. |

| S | Tapered adapter (SPHERE-ROL) or cast steel housing (pillow block series). |

| SAP | Split housing with SPHERE-ROL bearing (cast iron housing). |

| SB | Single-row spherical roller bearing (SPHERE-ROL). |

| SC | Pillow block ball bearing (manufactured for Dodge). |

| SDAF | Heavy-duty split housing with SPHERE-ROL bearing (cast iron housing). |

| SE | Special “MO” and related “MI” bearings (including all solid lip-type bearings). |

| SEE | SPHERE-ROL with eccentric locknut for pillow block mounting. |

| SFBA | SPHERE-ROL adapter mounted in flange pillow block. |

| SFEE | Reserved. |

| SK | Special design bearings or components. |

| SMO | MULTIROL with spherical outer diameter. |

| SNW | Complete tapered adapter assembly (sleeve, nut, lockwasher) for SPHERE-ROL. |

| SPBA | SPHERE-ROL adapter mounted in base pillow block. |

| SPBE | SPHERE-ROL with eccentric locknut, mounted in base pillow block. |

| SR | Special RS, RD, OS |

|

Additional Characters |

Meaning |

|

+E |

CAMROL with eccentric bushing on stem |

|

+L |

CAMROL with lubrication disc feature |

|

AN |

SPHERE-ROL with large locknut |

|

ASMO |

MULTIROL single-row, self-aligning with spherical housing |

To select the right bearing, refer to part numbers for key specs:

|

Common Errors in Interpreting Part Numbers |

How to Avoid These Errors |

|

Mistaking prefixes and suffixes |

Familiarize yourself with the current nomenclature charts provided by McGill. |

|

Using obsolete suffixes without checking updates |

Regularly check for updates or changes in the part number system. |

|

Ignoring clearance and material specifications |

Pay close attention to suffixes that indicate clearance (e.g., .C2, .C3) and material types (e.g., .CR for stainless steel). |

|

Confusing similar part numbers |

Double-check each character in the part number to ensure accuracy. |

|

Not consulting for unique features |

Use additional characters (e.g., +E, +L, AN, ASMO) as a guide for special features and consult McGill's documentation for detailed explanations. |

In 1937, McGill invented the needle bearing cam follower, which marked a milestone for precision control. This innovation spurred advancements in aerospace, where spherical bearings now provide self-aligning support and reduced friction, enhancing performance and reliability in critical applications.

McGill Bearings cut operating costs by enhancing reliability and reducing friction. They ease installation with precise fit and design, lower maintenance needs through durable materials, and minimize downtime.

Lab tests show CAMROL bearings lasting up to 24 times longer than competitors, demonstrating superior longevity.

McGill Bearings offers a range of products. CAMROL® is for precision control, TRAKROL® is for linear motion, and CAGEROL® is for heavy loads. GUIDEROL® is for guidance, and SPHERE-ROL® for self-aligning capabilities. These products boost operating efficiencies in industries like automotive, aerospace, and construction by ensuring smooth operation, reduced maintenance, and increased reliability.

Maintain McGill Bearings with regular inspections, proper lubrication, and alignment checks. This prolongs equipment life and enhances performance. For alternatives, consider LILY Bearing, offering comparable reliability—contact them for consultation.

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...

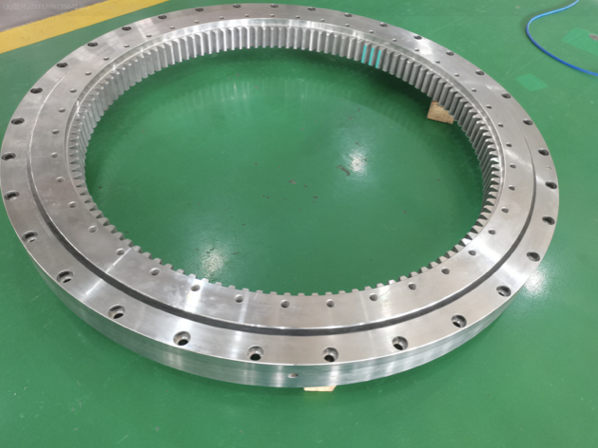

LILY has supplied assistance in Tesla’s create new products at the Gigafactory, a special custom slewing bearing made by Lily Bearing will soon start...

Importance of Bearings in Mechanical Systems Bearings are crucial for smooth and efficient motion in mechanical systems, while reducing friction,...