What is a Cam Follower Used For?

In the vast expanse of mechanical engineering, few mechanisms are as indispensable as the cam and its accompanying cam follower. They not only...

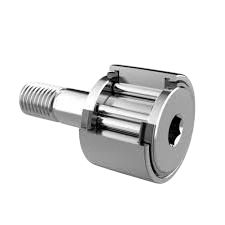

Cam followers, or cam follower bearings, come with a cage for holding the rollers, and another with a full complement of rollers without a cage.

They can also have a shield to protect the insides or be fully sealed to keep out dirt. The outer rings of these followers can be either round (spherical) or have flat sides (cylindrical cam).

They convert rotational motion into linear motion. They move along a camshaft or a track, making sure the sliding movement is smooth and exact. This is especially important for automated machinery, production lines, and conveyor systems.

Proper maintenance is crucial for making sure they last a long time. Cam followers are subject to significant stress and wear because of their continuous contact with the track and the loads they bear. Well-maintained cam followers help to prevent them from early wear, equipment malfunction and increased downtime, which can cost a lot for any business.

Neglecting maintenance can lead to a range of issues, from reduced efficiency to complete system failure.

For example, inadequate lubrication can cause too much friction. This can cause overheating and potential damage to the bearing and the track. Besides, debris or dirt can make them wear out faster and might even make them move weirdly or stop working altogether.

A regular visual inspection is a great way to keep cam followers in good shape. When you do this, look for signs of wear such as uneven rotation, damage, or misalignment. Also, make sure to check the crowned outer rings, and sealing elements for dirt or debris. These things can affect the bearing's performance and service life.

Keeping cam follower bearings well-lubricated is key to reducing friction and stopping them from wearing out.

No matter if you opt for grease, oil, or Ester-based lubricants, picking the right one plays a crucial role in ensuring your bearings run smoothly and efficiently.

Things like dust, moisture, and high temperatures can change how much proper lubrication your cam follower bearings need. For example, in dusty environments, you might need to use a heavier grease to stop dirt from getting into the bearings. Also pay attention to grease Temperature Limits:

How often you need to lubricate your cam follower bearings depends on several factors, such as the intensity of their workload and the type of lubricant applied. We recommend you to check what the maker of your bearings suggests. But in general, if your bearings are under high-load or high-speed working conditions, you'll need to lubricate them more often.

Overloading can lead to increased stress on the bearing, resulting in premature failure and reduce its service life.

To ensure that the cam follower bearing is not overloaded, it's important to monitor the bearing load. This involves selecting the right bearing for your application based on its load capacity. Here are some tips on this:

Correct installation is crucial to avoid stress and wear on cam followers. To make sure your cam follower is set up just right with the load, follow these simple steps:

Getting the torque settings right when you install the cam follower is extremely important. Always check the maker's torque table to make sure you're not too tight or too loose with the bearing.

Table 1 Maximum Tightening Torque of the Screw By THK

|

Model No. |

Maximum tightening torque (N・m) |

|

CF, CFN, CFH, CFT, CFS and NUCF |

|

|

3 |

0.392 |

|

4 |

0.98 |

|

5 |

1.96 |

|

6 |

2.94 |

|

8 |

7.84 |

|

10 10-1 |

16.7 |

|

12 12-1 |

29.4 |

|

16 |

70.6 |

|

18 |

98 |

|

20 20-1 |

137 |

|

24 24-1 |

245 * |

|

30 30-1 30-2 |

480 * |

Note) * is the value in case of the standard material (carbon steel). If a stainless steel type is to be used, the maximum value is 70% of this value.1 N・m equals to 0.102 kgf-m.

Cam follower failures often happen because of improper lubrication, pollution, and overload. Signs of potential cam follower failures include excessive noise, play or slack in movement, and unusual heat.

You should address these promptly. This may involve cleaning the bearing, reapplying lubricant, checking alignment and fit or adjusting the load on the bearing.

Self-lubricating cam followers are engineered with built-in lubrication, reducing the need for frequent greasing. This feature reduces maintenance time and labor costs.

For example, RBC Roller® and IKO C-Lube cam followers require less frequent lubrication.

A lot of RBC Roller® models have enough space inside to store extra grease. This helps them work without frequent lubrication because the grease stays put and dirt stays out.

IKO's C-Lube technology uses a special, long-lasting lubricant pre-packed into the bearing space. As the bearing spins, this lubricant keeps rolling elements running smoothly.

These maintenance-free options can lead to significant cost-saving over time.

If you're looking to upgrade to maintenance-free cam followers, choosing the correct type (yoke type, stud type or eccentric type) for your specific application is key. You might need to talk to an expert or check the manufacturer's recommendations to make sure the cam followers will work well with your existing system. Also consider installation tips and expected cost savings over time when making the transition.

Regular maintenance is crucial for extended lifespan of cam followers and smooth operation of heavy-duty machinery. By sticking to best practices for inspection, lubrication, and load monitoring, you can reduce the risk of failure and maximize the efficiency of your systems.

Besides, you might consider maintenance-free cam followers to save money and makes your equipment more reliable.

They can significantly reduce the time spent on inspections and lubrication, saving you money and increasing the reliability of your equipment.

Please don't hesitate to contact LILY’s expert or explore solutions to make your bearing maintenance even better.

In the vast expanse of mechanical engineering, few mechanisms are as indispensable as the cam and its accompanying cam follower. They not only...

Cam follower bearings provide smooth linear movement as the cam rotates, which minimizes wear better than sliding contacts. This blog explores the...

Cam followers, also known as cam and followers, are crucial parts in many mechanical systems. They convert rotational motion into linear motion,...