What Are the Three Main Types of Mounted Bearings?

Mounted bearings are vital for keeping industrial machines running smoothly. They support rotating shafts, align them properly, reduce friction, and...

Table of Contents

In the realm of modern machinery, linear bearings stand out as pivotal elements.

Their role is monumental, but it's the meticulous design behind them that truly drives system performance.

This linear bearing design guide delves deep into these design intricacies, aiming to provide both professionals and enthusiasts a roadmap to achieving optimal functionality and efficiency.

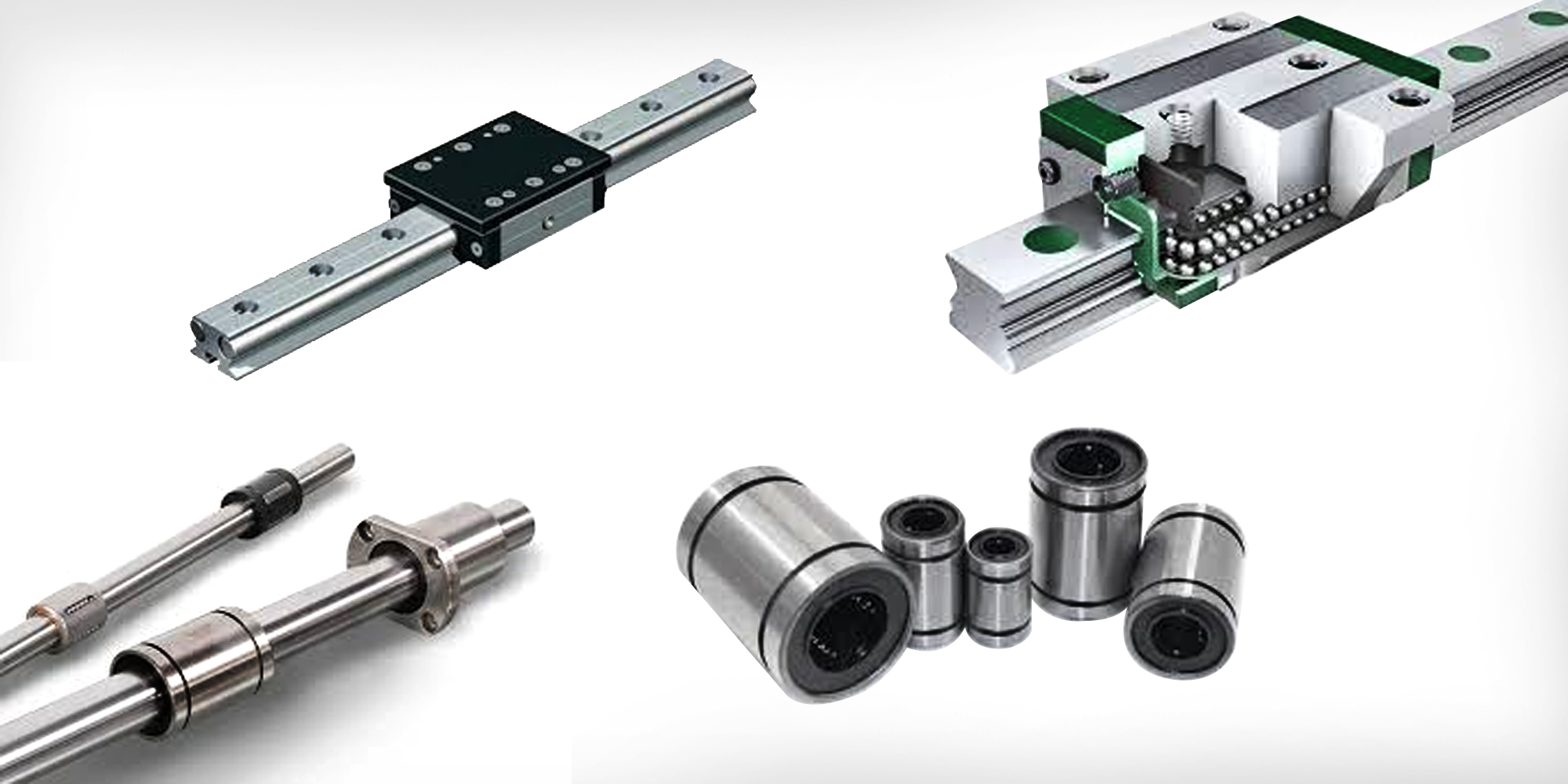

At their core, linear bearings are mechanical elements that allow free motion in one direction, typically along a straight line.

Unlike rotary bearings, which permit rotation, linear bearings facilitate linear movement, reducing friction between moving parts.

Plain bearings: These are simple bearings that work on the principle of sliding motion. They are often cylindrical sleeves that allow a shaft to slide inside, with lubrication aiding in smooth movement. These bearings include:

Linear Sleeve Bearings for Support Rail Shafts

Mounted Linear Sleeve Bearings

Mounted Linear Sleeve Bearings for Support Rail Shafts

Rolling element bearings: More complex than plain bearings, these utilize balls or rollers to support loads and reduce friction. Depending on the design, the rolling elements recirculate within the bearing or remain non-recirculating. These bearings include:

Linear Ball Bearings for Support Rail Shafts

Mounted Linear Ball Bearings for Support Rail Shafts

Linear Bearings for Spline Shafts

Mounted Linear Bearings for Spline Shafts

Whether sliding or rolling, linear bearings operate by ensuring that the moving parts do not have direct contact, thus reducing wear and friction.

Linear bearing design is influenced by a range of technical and operational factors.

Designing an efficient linear bearing system requires precision and foresight:

Recognizing that each industry possesses unique challenges and operational requirements, it's essential to customize linear bearing designs.

Whether it's the high-speed demands of the automotive industry or the precision needs in medical equipment, tailored solutions enhance both performance and reliability.

Numerous industries have benefited from bespoke linear bearing designs.

For instance, in the aerospace sector, custom bearings have proven critical in ensuring aircraft safety and efficiency.

Meanwhile, in the food processing industry, specially designed bearings that resist corrosion and contamination have maximized production uptime.

These success stories underscore the value of industry-specific bearing solutions.

For optimal linear bearing design, always select materials suitable for the intended application and ensure correct alignment.

Conversely, avoid overloading or improperly fitting components.

When issues arise, regular checks can swiftly pinpoint typical problems, such as misalignment or uneven wear.

Lastly, consistent maintenance and lubrication are paramount for ensuring both longevity and peak system performance.

In the realm of machinery, understanding linear bearing design fundamentals is pivotal.

These principles ensure efficient operation and pave the way for innovative advancements.

As we've explored in this guide, optimizing system performance is a continuous journey that demands attention to detail and adaptation to evolving trends.

Embracing these principles guarantees peak machine functionality, ensuring durability and efficiency.

Mounted bearings are vital for keeping industrial machines running smoothly. They support rotating shafts, align them properly, reduce friction, and...

In the vast world of machinery, ever pondered the question, "how do bearings work?" These unassuming devices play a monumental role in numerous...

Industrial bearings are essential in industrial machinery, enabling smooth operation and reducing wear for prolonged equipment life. There exists a...