L44649 Bearing Guide: Uses, Benefits & Upkeep

Bearings are key parts that help things move smoothly, reduce friction, and make machines and vehicles last longer. The L44649 bearing is commonly...

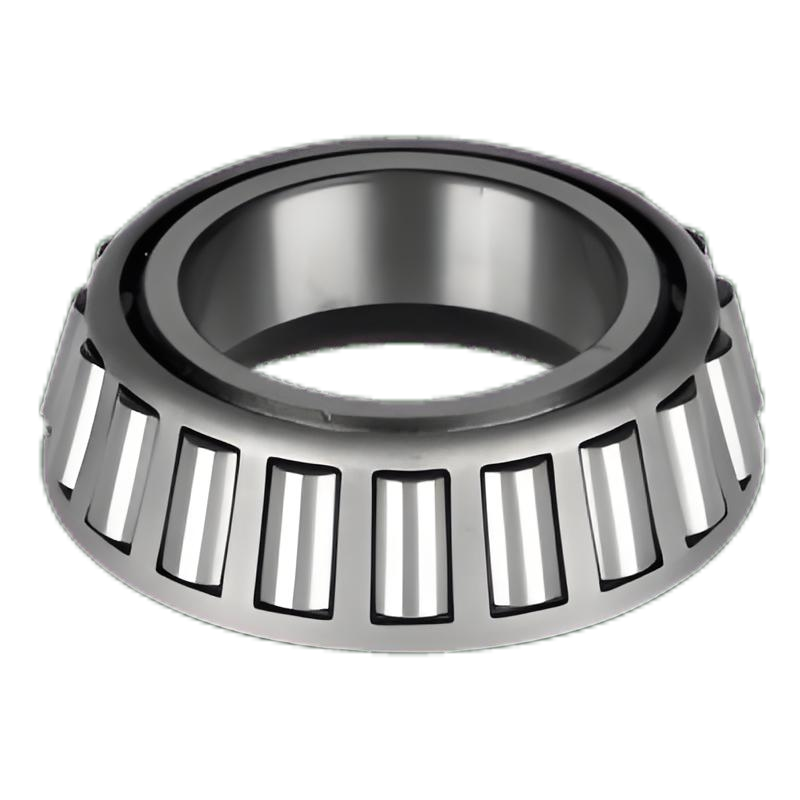

The L44643 bearing is a tapered roller bearing commonly used in trailer axles, automotive components, and various machinery applications. It provides reliable performance in demanding environments.

The L44643 bearing is widely used because it can handle heavy loads and work under stress. Its durable design reduces friction, ensuring smooth operation in trailer axles, cars, and machinery. This helps equipment run reliably and last longer.

The purpose of the guide is to provide detailed information on its specifications, benefits, applications, and installation tips. performance in various equipment and applications. It aims to help users understand how to choose, install, and maintain the bearing. This ensures optimal durability and performance in various equipment and applications.

The L44643 is a tapered roller bearing cone designed to manage both radial and axial loads. The L44643 is designed to be compatible with the L44610 cup. Together, they form a complete bearing assembly that ensures reliable performance in various applications.

The L44643 bearing is highly durable, resistant to wear, and designed for long-lasting performance. It can handle heavy radial and axial loads, making it ideal for tough applications. Its design also allows for smooth, efficient operation at high speeds.

The L44643 is the cone (inner ring) of the bearing, while the L44610 is the cup (outer ring). Together, they form a complete tapered roller bearing. The cone fits inside the cup, allowing smooth rotation and managing both radial and axial loads.

The separable design of the L44643 bearing allows the cone and cup to be easily separated. This feature makes installation and replacement simpler. The cone and cup can be handled individually, reducing the time and effort required for maintenance or part replacement.

The L44643 is typically made of high-quality chrome steel, which provides excellent strength, durability, and corrosion resistance. This material ensures reliable performance even in demanding conditions, extending the bearing's lifespan.

Suitable for temperatures from -30°C to 110°C

The L44643 bearing is RoHS and REACH compliant.

The L44643 bearing is commonly used in trailer wheel hubs, especially for 2,000 lb axles and BT8 spindles. It is designed to handle the loads and stresses of light-duty trailers. This ensures smooth wheel rotation and stable performance.

The L44643 bearing is also used in heavy machinery, including mills, metalworking equipment, and plastic machinery. Its high load capacity and durability make it suitable for demanding applications. It supports smooth, reliable operation even under high stress and heavy loads.

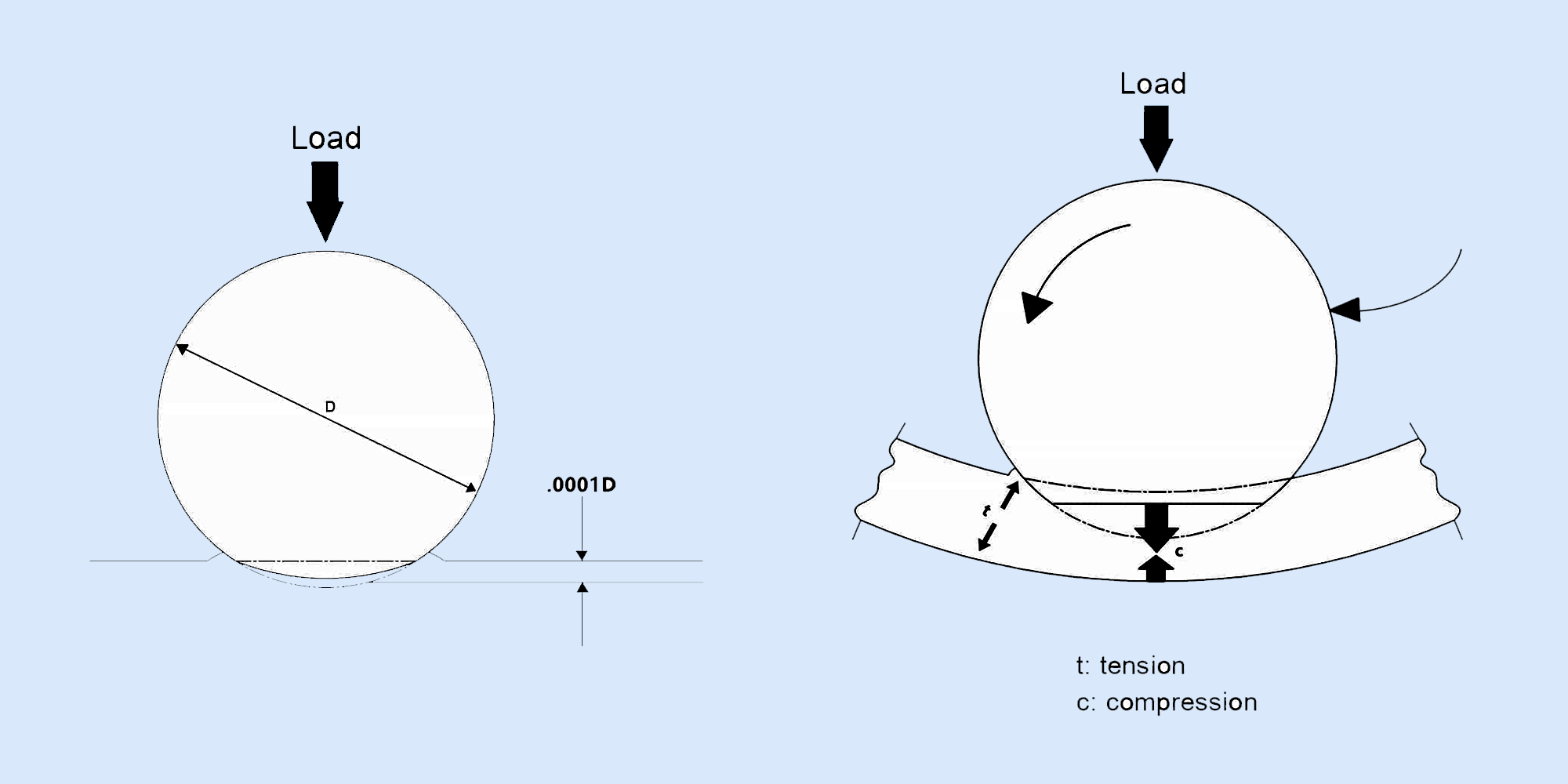

The tapered design of the L44643 bearing allows it to support both radial loads and axial loads. This design ensures that the bearing can handle forces from multiple directions. This makes it ideal for demanding applications where both types of loads are present.

The L44643 bearing is made from high-grade chrome steel, which ensures exceptional longevity and consistent performance. This material provides excellent resistance to wear and corrosion. It allows the bearing to perform reliably over extended periods, even in tough conditions.

The L44643 bearing's design and high-quality material make it suitable for a wide range of uses. Ideal for applications ranging from trailers to industrial machines, the L44643 bearing offers versatile performance. Its durability and load-carrying capacity ensure reliable performance in both light-duty and heavy-duty applications.

Inadequate lubrication and bearing misalignment are common causes of bearing failure. Without proper lubrication, friction and wear increase, leading to overheating and premature failure.

To prevent this, regularly grease the bearing with the correct amount and type of grease, and check for leaks. Improper alignment during installation or wear over time can lead to uneven distribution of load. This may result in noise, vibration, and early bearing failure.

To avoid this, ensure proper alignment during installation and inspect components for misalignment before reassembling. Promptly addressing these issues can significantly extend the bearing’s lifespan and ensure reliable performance.

Overheating is a common problem caused by excess friction in the bearing. This can lead to premature wear and failure. To prevent overheating, ensure proper lubrication to reduce friction and manage the load within the bearing's specified limits. Regularly check for adequate grease and avoid overloading the bearing to maintain smooth operation and prolong its lifespan.

Dirt, corrosion, and incorrect installation can cause L44643 bearing failure. Dirt and debris can increase friction and wear, while corrosion weakens the bearing, leading to cracks. Incorrect installation, like misalignment, can cause uneven wear.

To prevent these problems, keep the bearing clean and properly sealed to avoid dirt. Use corrosion-resistant materials and store bearings in dry, clean areas. Follow correct installation guidelines for proper alignment and seating to ensure long-lasting performance.

The L44643 is the cone (inner ring) of the bearing. The L44610 is the cup (outer ring) that the cone fits into, together forming a complete tapered roller bearing assembly.

Replace the L44643 bearing if you hear unusual noise, feel vibration, or notice excessive friction. Also, replace it if you see visible damage, such as cracks or wear. Rust, corrosion, or difficulty rotating smoothly also indicate it needs replacement.

Yes, the L44643 bearing can be used for high-speed applications. It is designed to handle both radial and axial loads effectively. However, it is important to ensure proper lubrication and load management to maintain performance at higher speeds.

It is generally recommended to grease the bearing every 6 to 12 months. For trailer applications, grease it after every 10,000 to 20,000 miles.

The L44643 bearing is durable and has a high load capacity. It can handle both radial and axial loads, making it ideal for trailers, vehicles, and heavy machinery. Made of high-quality chrome steel, it offers long-lasting performance.

Regular greasing, inspections for wear, and proper installation are key to maintaining it. Keeping up with maintenance will extend the L44643 bearing’s lifespan and ensure reliable performance.

Explore more about L44643 bearings to learn how they can improve your equipment's performance and longevity. If you have any questions or need help, contact us for more information and support.

Bearings are key parts that help things move smoothly, reduce friction, and make machines and vehicles last longer. The L44649 bearing is commonly...

What is the L44610 Tapered Bearing? The L44610 tapered bearing is a single-cup roller bearing from the L44600 series. It is known for its strong...

Bearings play a vital role in machinery by ensuring smooth motion and reducing friction. Understanding load capacities, specifically static load vs...