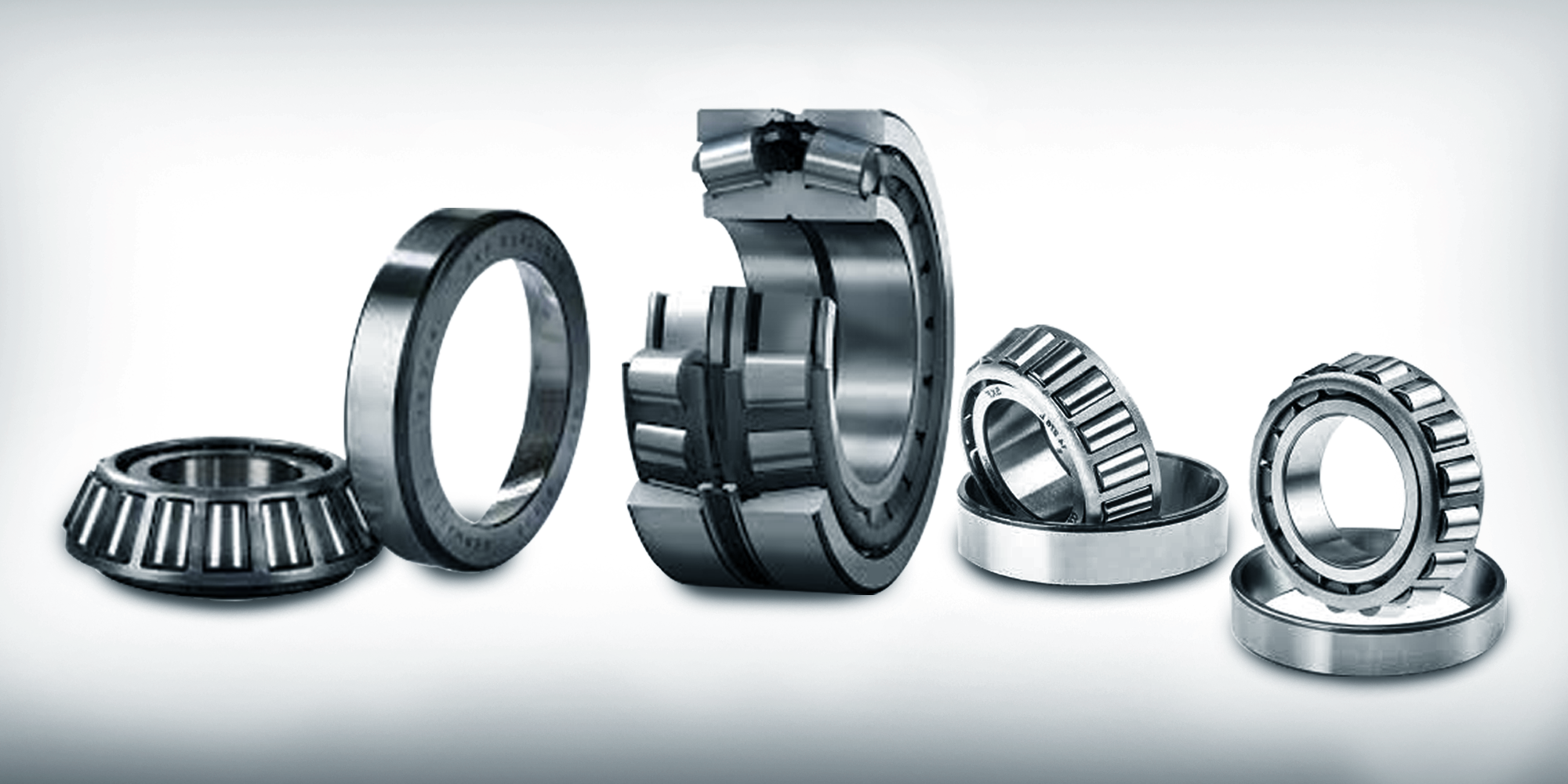

Single Row Tapered Roller Bearings from LYC & Wind Turbine Field

Not long ago, LYC developed a set of 16 MW platformwind power spindle bearings. The bearings beenthe largest poweredwind power spindle bearingsin...

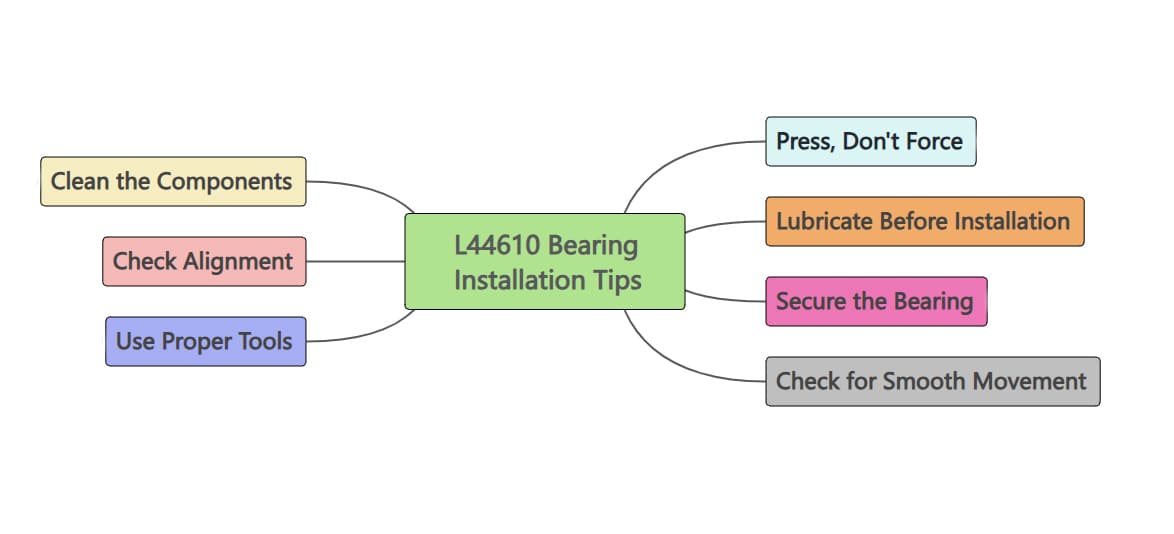

The L44610 tapered bearing is a single-cup roller bearing from the L44600 series. It is known for its strong performance and reliability. This bearing is compatible with Timken L44600 bearings. The L44610 bearing offers versatility for various applications that require precise and durable performance.

The L44610 tapered bearing plays an important role in supporting both radial and axial loads in various machinery.

Choosing the right bearing is important to keep your equipment running smoothly. It also helps extend its life and avoid expensive failures. The right bearing can handle the specific loads, speeds, and conditions your machinery faces.

Using the wrong bearing can cause extra wear, overheating, and breakdowns. This leads to costly repairs and lost productivity.

Chrome steel is chosen for its strength and durability. The L44610 bearing is ideal for handling high loads and performing reliably under harsh conditions. This material enhances the bearing's resistance to wear and corrosion. It ensures long-lasting performance in demanding applications.

The bearing has a temperature range of -30°C to 110°C, ensuring versatility across various environments.

The ABEC-1 rating ensures standard bearing precision. It offers reliable performance for a wide range of general applications.

RoHS and REACH compliant ensures the bearing is free from hazardous substances. It meets strict environmental regulations for safety and sustainability. It aligns with industry standards for safety. This helps protect both human health and the environment.

The L44610 bearing is ideal for applications with high radial and axial load demands. This is because of its strong load ratings. With a dynamic load rating of 28.8 kN, the L44610 bearing can handle heavy forces.

This makes it perfect for high-speed machinery. It also supports axial loads (forces along the shaft), making it suitable for applications like gearboxes or conveyors.

Additionally, the Static Load Rating of 34 kN ensures the bearing can withstand heavy stationary loads without damage. These load ratings make the L44610 bearing reliable and durable. Well-suited for demanding machines that experience both radial and axial forces.

The L44610 bearing has a speed limit of 7,500 RPM, making it suitable for medium to high-speed applications.

Using light oil lubrication helps the L44610 bearing run smoothly and reduces friction. This makes it last longer and work reliably in different applications.

Proper lubrication is important for keeping bearings working well and lasting longer. Here's why:

The L44610 bearing is designed to accommodate misalignment between the shaft and housing. This is important in environments where shaft deflection is common. Here's how it works:

The L44610 tapered roller bearing is commonly used in automotive components like wheel hubs, gearboxes, and axles. These applications require both radial and axial load handling:

The L44610 bearing plays a critical role in heavy machinery, such as conveyor systems and mining equipment. High-load and heavy-duty performance is essential in this case, and the L44610 bearing meets these demands. Here's how it contributes:

The L44610 bearing is perfect for both agriculture and aerospace machinery, where reliable performance is needed in tough conditions. In agriculture, it handles dust, dirt, moisture, and heavy loads in equipment like tractors and harvesters. In aerospace, it works well in extreme temperatures and high speeds, supporting systems like landing gears and engines. In both fields, the L44610 ensures durability, efficiency, and low maintenance, making it great for heavy-duty use.

The L44610 tapered roller bearing is known for its durability and high load capacity. Especially in high-speed and heavy-duty applications, the L44610 tapered roller bearing is highly effective. The L44610 bearing's design allows it to handle both radial and axial loads at the same time. This makes it perfect for uses like automotive wheel hubs, gearboxes, and mining equipment, where both types of loads are common.

The L44610 tapered roller bearing has several advantages over other types:

The L44610 bearing is a cost-effective choice for high-load applications, offering great performance and value. It can handle both radial and axial loads, providing strong load capacity. This makes it a more cost-effective option compared to some other bearings. Its durability means fewer replacements and less maintenance over time.

The bearing is versatile, working in many industries like automotive and machinery, and its reliability helps reduce downtime. Overall, the L44610 bearing gives you good performance for a great price, making it perfect for heavy-duty use.

The L44610 bearing helps extend the service life of machinery by performing reliably in tough conditions. This also helps lower maintenance costs. It handles both radial and axial loads, reducing wear and tear.

Its durability means fewer replacements are needed, saving money and time. By keeping machinery running smoothly, it reduces downtime and the need for expensive repairs. Over time, the L44610 bearing provides great value by being both reliable and low-maintenance.

Using the right lubrication, like light oil or grease, is important for the L44610 bearing to run smoothly and last longer. Lubrication reduces friction between moving parts and prevents heat buildup, which can cause wear and damage. It also helps cool the bearing, keeping it working efficiently. Without proper lubrication, the bearing can wear out faster, overheat, and fail, reducing L44610 bearing reliability and lifespan.

Both under-lubrication and over-lubrication can cause problems for the bearing. With too little lubrication, friction increases, causing heat and wear, which can lead to the bearing failing. Too much lubrication can create extra heat and pressure, damaging seals and making the bearing work less efficiently.

Both problems shorten the bearing's service life and can lead to costly repairs. Therefore, it’s important to use the right amount of lubrication for the best performance.

Regularly inspecting the L44610 bearing is important to catch any signs of wear, damage, or too much lubrication early. This helps avoid bigger problems, saves money on repairs, and keeps machinery running smoothly. Checking the bearing regularly also makes sure it gets the right lubrication and lasts longer.

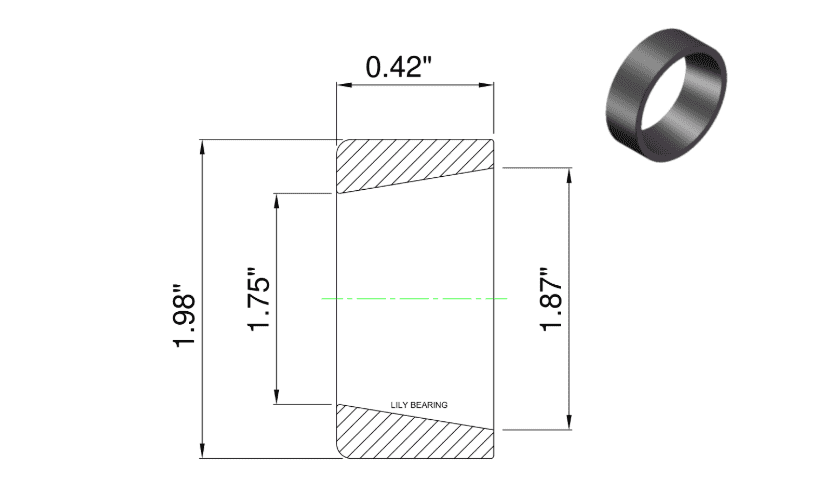

The L44610 tapered roller bearing has a 1.9800-inch outer diameter and a 0.4200-inch cup width. It can handle both radial and axial loads. With a dynamic load rating of 28.8 kN and a static load rating of 34 kN, it is ideal for heavy-duty applications.

The bearing operates up to 7,500 RPM and in temperatures from -30°C to 110°C. It is commonly used in automotive wheel hubs, gearboxes, and axles. The bearing is also ideal for heavy machinery where high durability and load capacity are required.

Choosing the right bearing is important because it ensures your equipment works smoothly and lasts longer. Consider the bearing load capacity, speed, and alignment needs of your application. Select a bearing that can handle the forces it will face. The right bearing will improve performance, reduce wear, and prevent costly breakdowns.

If you are uncertain about which bearing to select, please contact LILY Bearing for expert guidance. Our experts can help you pick the right L44610 tapered bearing or any other bearing for your needs. We're here to assist with all your bearing questions.

Not long ago, LYC developed a set of 16 MW platformwind power spindle bearings. The bearings beenthe largest poweredwind power spindle bearingsin...

In the world of mechanical systems, tapered roller bearings play a crucial role. They are unique in their design and function, handling both radial...

Roller bearings are indispensable in modern industrial machinery, playing a pivotal role in various applications. This article aims to elucidate the...