Characteristics, Uses and Advantages of Stainless Steel Bearings

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...

Kaydon bearings are leaders in bearing technology. Kaydon provides cutting-edge solutions for tough tasks in industries like aerospace, construction, and clean energy.

Kaydon’s thin and sleek bearings, such as Kaydo Reali-Slim bearings, are crucial today's machinery. They can save space, handle heavy loads, and ensure accuracy.

Kaydon bearings are vital for jobs that involve shifting heavy loads and need exact placement. That's what makes Kaydon a dependable partner in improving the technology we use in industry.

Kaydon's thin section bearings are made to be light and occupy less space, perfect for applications where room is limited. They are different from standard bearings with their constant cross section as bore diameter increases.

They make machines lighter, occupy less room, and work with pinpoint precision, ideal for industries where smooth operation and flexible design are key.

Kaydon's Reali-Slim® and Ultra-Slim® series are advanced thin section bearings. They come in a wide range of materials, cross-sections, and internal fit-ups.

They cover a wide range of uses, with bore sizes varying from 19 mm to 1 meter, providing both design freedom and strong performance.

These bearings are known for their lightweight design, reduced space usage, and high precision. They cater to sectors such as aerospace and medical devices.

Thin section bearings by Kaydon are pivotal in high-precision applications. In Aerospace they are used for satellites and guidance systems. In robotics, they're crucial for the moving parts of machines, and in medical devices, they're key for MRI scanners and surgical robots.

Kaydon bearings offer the exact precision and dependable performance that these important technologies need.

Kaydon's thin section bearings have less friction and more design options than regular bearings, which boosts their performance.

They ensure machines run with high precision, which is essential for precision equipment. While they might seem pricey at first, the improvements in efficiency and reduced maintenance over time can pay off more than the initial cost. So, they're a wise pick for demanding jobs.

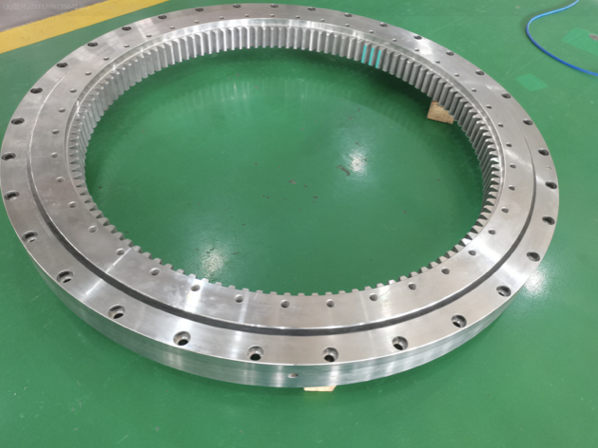

Kaydon slewing ring bearings are designed to handle a combination of radial, axial, and moment loads at the same time. They're a go-to choice for machinery that needs to spin, like cranes, wind turbines, and factory turntables. These bearings let heavy equipment find its mark with perfect accuracy. This shows their unique ability to handle heavy loads while still spinning smoothly.

Slewing bearings by Kaydon are crucial across industries. In construction for cranes and excavators, they provide the pivot for heavy lifting. They enable smooth 360-degree turns for efficient handling of materials.

In the renewable energy sector, such as in wind turbines, these bearings help to adjust the nacelles and blades to capture the maximum amount of wind power.

These bearings are essential for the precise functioning of military radar and turret systems. They play a key role in effective surveillance and defense. These bearings can spin smoothly even in tough situations all over the place.

Thin section bearings are crafted to save space, making them perfect for compact applications in fields like robotics and aerospace.

Slewing bearings stand out for their ability to handle heavy loads.

Slewing bearings allow heavy machinery, such as cranes and excavators, to handle and move massive loads. In wind turbines, a part of renewable energy, they withstand the large forces from spinning rotors, keeping the turbines running smoothly and dependably over time.

Deciding between thin section and slewing bearings depends on what you need them for.

Thin section bearings are chosen for applications needing to save space and weight, such as aerospace and medical devices, where precision is crucial. In aerospace, thin section bearings are used in gyroscopes and reaction wheels.

Slewing bearings, on the other hand, are perfect for heavy-duty machines like construction equipment and wind turbines. They can handle a lot of weight and keep things spinning smoothly.

Kaydon's selector tool makes it easy for engineers to pick the perfect bearing. They can search by bearing type, dimension, cross section and load capability. It helps them find the right fit for jobs that need to spin smoothly.

This handy tool simplifies the process of choosing the right bearing for a specific job, making sure it's the best fit.

What's more, engineers can easily download 3D CAD models of these bearings, making it simpler and more accurate to integrate them into design work. This boosts both the speed and precision of their designs.

Kaydon bearings uses different materials for their bearings to meet various needs. They use stainless steel to fight corrosion, which is great for wet or chemical-filled places. And they also have ceramic bearings that are perfect for jobs that need to be super exact and smooth, with less friction.

They provide lots of ways to customize bearings, so they are useful in different industries. You can pick things like their materials, their shape, their static loads, separation mechanisms, and how they fit inside. This means they can be perfect for all sorts of jobs and work well no matter what conditions they're in.

Kaydon bearings save money in the long run because they last a long time and work perfectly well. They don't need much fixing because they use strong materials with precise engineering. This means your machines will stay in good shape for longer.

Take wind turbines, for example; Kaydon's strong slewing bearings keep them running smoothly with less time off. And in medical devices, Kaydon thin section bearings help make sure everything works accurately and lasts a long time with little need for repairs.

Consider how much weight they'll handle, the space available, how fast they spin, and the conditions they'll face. For things like robots and medical gear, being able to move just right is key to their performance and safety. Picking the right Kaydon bearing based on these points helps machines run their best and last longer.

Use Kaydon's bearing selector tool to quickly find the best bearings for your needs. If you need something special, talking to your bearing experts will surely be helpful. They make sure you get the right bearings for your unique setup and make your machines work even better.

Kaydon's bearings are well-known for being flexible and dependable. Kaydon bearings make machines perform more efficiently and last longer across various fields.

If you're searching for superior bearings from alternative brands, LILY Bearings is a top choice. They offer reliable and budget-friendly alternatives that work well for all kinds of uses.

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...

LILY has supplied assistance in Tesla’s create new products at the Gigafactory, a special custom slewing bearing made by Lily Bearing will soon start...

Importance of Bearings in Mechanical Systems Bearings are crucial for smooth and efficient motion in mechanical systems, while reducing friction,...