Expert Tips On Installing & Removing Bearings for Industry Professionals

Bearings play a critical role in the health of industrial machinery, ensuring operations run without a hitch. The processes of 'how to install a...

Removing a bearing from machinery is a critical task that can influence the longevity and performance of both the bearing and the equipment itself. Understanding how to remove a bearing with precision and care is paramount to ensure the machinery's integrity and the safety of the operator. This comprehensive guide will outline the key methods and tips for efficient bearing removal, ensuring you're equipped with the knowledge to perform this task effectively.

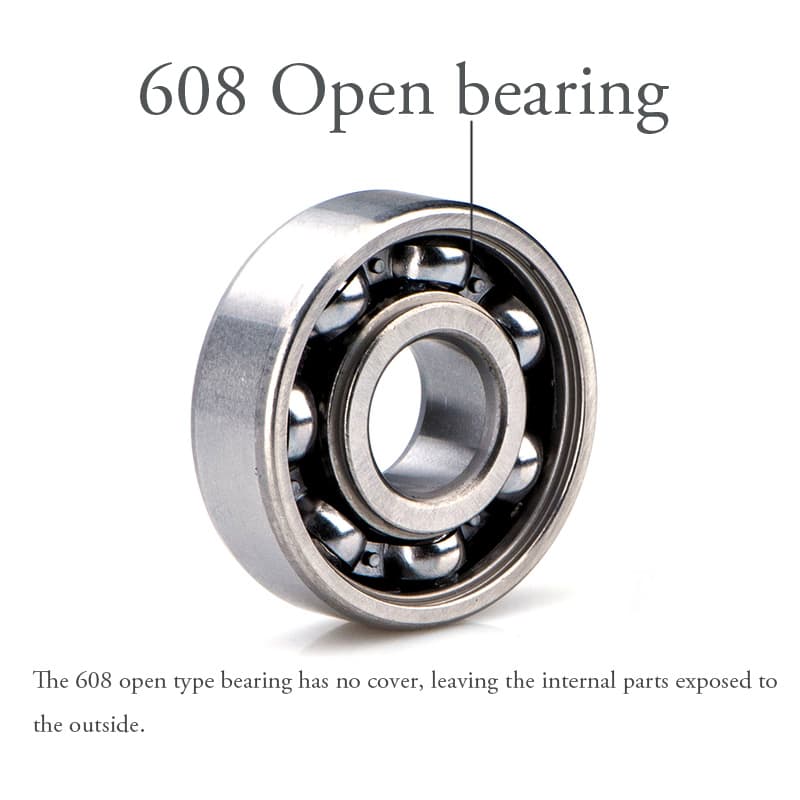

Bearing removal refers to the process of detaching bearings from their operational position within machinery or equipment. The removal process involves carefully extracting these bearings without causing damage to either the bearings themselves or the shaft as well as the other surrounding components. This task requires specific tools and techniques, depending on the type of bearing, its location, and how it is mounted within the machinery.

Proper bearing removal is essential for safeguarding equipment from damage, ensuring the safety of maintenance personnel, and maintaining the integrity of the industrial bearings for potential reuse. Employing correct techniques not only prevents costly repairs and downtime but also enhances operational efficiency and ensures compliance with relevant safety and industrial standards. This approach is vital in minimizing risks and expenses while maximizing the longevity and performance of machinery.

Here, we provide a detailed look at various removal techniques and offers professional advice to tackle the task at hand.

The bearing puller is a specialized tool designed for the safe and efficient removal of bearings. This method is favorable for several reasons:

Hydraulic methods for bearing removal are a specialized technique employed in specific scenarios where conventional methods may not be feasible or effective. Understanding when and how to use these methods can be crucial for ensuring the safe, efficient, and damage-free removal of bearings, particularly in industrial settings.

When to Use Hydraulics for Bearing Removal:

Hydraulic tools are often the go-to solution in situations where bearings are tightly fitted or are part of large and heavy machinery. These situations typically include:

The hot oil and steam method is a specialized technique for bearing removal, leveraging thermal expansion to ease the extraction process. It’s crucial to understand both the methodology and its associated risks for safe and effective use.

Understanding the Method:

Risks and Dangers:

Burn Hazards: Both hot oil and steam pose significant burn risks, necessitating stringent safety measures and protective gear.

The brute force method is the least recommended due to its potential to:

To ensure a safe and successful bearing removal process, consider the following tips:

It is worth noting that in instances where the bearing cannot be disassembled due to design constraints, it underscores the importance of considering bearing removal at the initial design stage of a product. This foresight can greatly simplify maintenance procedures and extend the lifecycle of both the bearing and the machinery. It's a proactive measure that ensures ease of disassembly without damage to components.

To conclude, this blog's insights on “how to remove a bearing” highlight the cruciality of choosing safe and effective removal methods. The right approach is key to protecting both the machinery and personnel. We advocate for careful selection of the appropriate removal technique tailored to each specific task. At Lily-Bearing, we underscore this with our commitment to providing high-quality bearings, ensuring dependable and durable performance in all applications. Trust Lily-Bearing for bearings that align with the industry's best practices in maintenance and removal.

Bearings play a critical role in the health of industrial machinery, ensuring operations run without a hitch. The processes of 'how to install a...

Compared with ordinary bearings, stainless steel bearings have stronger rust and corrosion resistance. They not only have obvious advantages in...

Industrial bearings are essential in industrial machinery, enabling smooth operation and reducing wear for prolonged equipment life. There exists a...