Explaining the Basics of Bearing Preload

Bearings are crucial components in the mechanical world, helping rotating equipment run smoothly and efficiently. Preloading a bearing is an...

Bearing numbers serve a valuable purpose in the classification of bearings.

They provide at-a-glance information about typical usage, durability, and suitability for specific applications.

Regardless of the brand, and even for custom bearings, if you have a grasp of the standard bearing number meaning, you can accurately identify the bearing you need.

It's crucial to note that bearing model designations aren't universally standardized and can vary by brand. For ease of reference and comparison, we have developed a special Bearing Cross Reference.

Next, we will present a more unified perspective on bearing codes, conforming to the widely accepted industry standards.

Typically, a bearing number is composed of three distinct parts: the prefix, the Basic Designation, and the suffix.

Take the NTN radial ball bearing code 'TS2- 6206 x1 LLB N C3 P5/2AS' as an example:

'TS2' represents the prefix, meaning “Heat stabilized up to 320°F (160°C)”;

'6206' is the Basic Designation - Digit Identification of Bearing;

'X1', 'LLB', 'C3', 'P5', 2AS' are the suffixes.

For some bearings, they are exclusively identified with numeric codes, devoid of any prefix or suffix, such as the bearing “6206”.

Some bearings only have suffixes, such as “6206 LLB C3 P5”.

Prefixes primarily indicate specific components of a bearing and can also identify various bearing variants. Let's take the NTN prefix as an example.

In terms of thermal stability:

|

Prefix |

Implication |

|

No Prefix |

Heat stabilized up to 250°F (120°C) |

|

TS2 |

Heat stabilized up to 320°F (160°C) |

|

TS3 |

Heat stabilized up to 390°F (200°C) |

|

TS4 |

Heat stabilized up to 480°F (250°C) |

|

5S |

Ceramic rolling elements |

|

7MC3 |

MEGAOHM® (ceramic coating) |

In terms of materials:

|

Prefix |

Implication |

|

No Symbol |

High carbon chrome bearing steel (equivalent to AISI E52100) |

|

F |

Martensitic stainless steel (equivalent to AISI 440C) |

|

N |

Beryllium Copper |

For SKF, its deep groove ball bearing code prefixes such as:

|

Prefix |

Implication |

|

D/W |

D/W |

|

ICOS- |

Oil sealed bearing unit |

|

W |

Stainless steel, metric dimensions |

|

WBB1 |

Stainless steel, metric dimensions, not in accordance with ISO dimension series |

The initial digit in bearing numbers carries substantial significance as it often denotes the type of a bearing. It is instrumental in identifying the bearing's core design.

For instance, in '6206', the first digit “6” refers to ‘Single row deep groove ball bearing’.

The following table lists various types of bearings alongside their type codes.

|

Type Code |

Type of Bearing |

|

1 |

Self Aligning Ball Bearing |

|

2 |

|

|

3 |

Double row Angular Contact Ball Bearing |

|

4 |

Double Row Ball Bearing |

|

5 |

Thrust Ball Bearing |

|

6 |

|

|

7 |

Single Row Angular Contact Bearing |

|

8 |

Felt Seal Bearing |

|

32/T |

Tapered Roller Bearing |

|

R |

Inch Bearing |

|

N |

Cylindrical Roller Bearing |

|

NN |

Double Row Roller Bearing |

|

NA |

Needle Roller Bearing |

|

BK |

Needle Roller Bearing with Closed end (Drawn Cup) |

|

HK |

Needle Roller Bearing with Open ends (Drawn Cup) |

|

C |

CARB Toroidal Roller Bearings |

|

K |

Needle Roller and Cage Thrust Assembly |

|

QJ |

Four-point Contact Ball Bearings |

The second digit in bearing numbers typically signifies the bearing series. It reflects the robustness of the bearing, with certain numbers indicating light, medium, or heavy series. Consequently, this digit provides valuable insight into the bearing's ability to handle different load conditions.

For instance, in '6206', the 2nd digit “2” refers to ‘Light’.

The table provided below represents the different bearing series alongside their corresponding numeric codes.

|

Series Code |

Series Description |

|

0 |

Extra Light |

|

1 |

Extra Light Thrust |

|

2 |

Light |

|

3 |

Medium |

|

4 |

Heavy |

|

8 |

Extra Thin Section |

|

9 |

Very Thin Section |

The third and fourth digits in bearing numbers are of great significance as they typically represent the the inner diameter (ID) of the bearing in millimeters. They provide crucial information about the bearing's fit with the shaft it will be mounted on.

Please see the table below.

|

Code |

Bore Size |

|

00 |

10mm |

|

01 |

12mm |

|

02 |

15mm |

|

03 |

17mm |

|

04 |

20mm (4*5mm) |

|

05 |

25mm (5*5mm) |

|

06 |

30mm (6*5mm) |

|

above |

Above=>multiplication of 500mm |

The bore size in bearing numbers ranges from 0 to 3, signifying 10 to 17 mm.

For numbers over '03', the bore size is calculated as 5 times the value represented by the 3rd and 4th digits in the bearing number.

For example, in “6206”, '06' corresponds to the bore size, and thus, “06” translates to a bearing bore size of 6*5=30 mm.

In scenarios where the fourth digit is absent from the bearing number, the third digit stands for the bore size.

For instance, for a bearing size of '234', the number '4'—equivalent to 4mm—denotes the bore size.

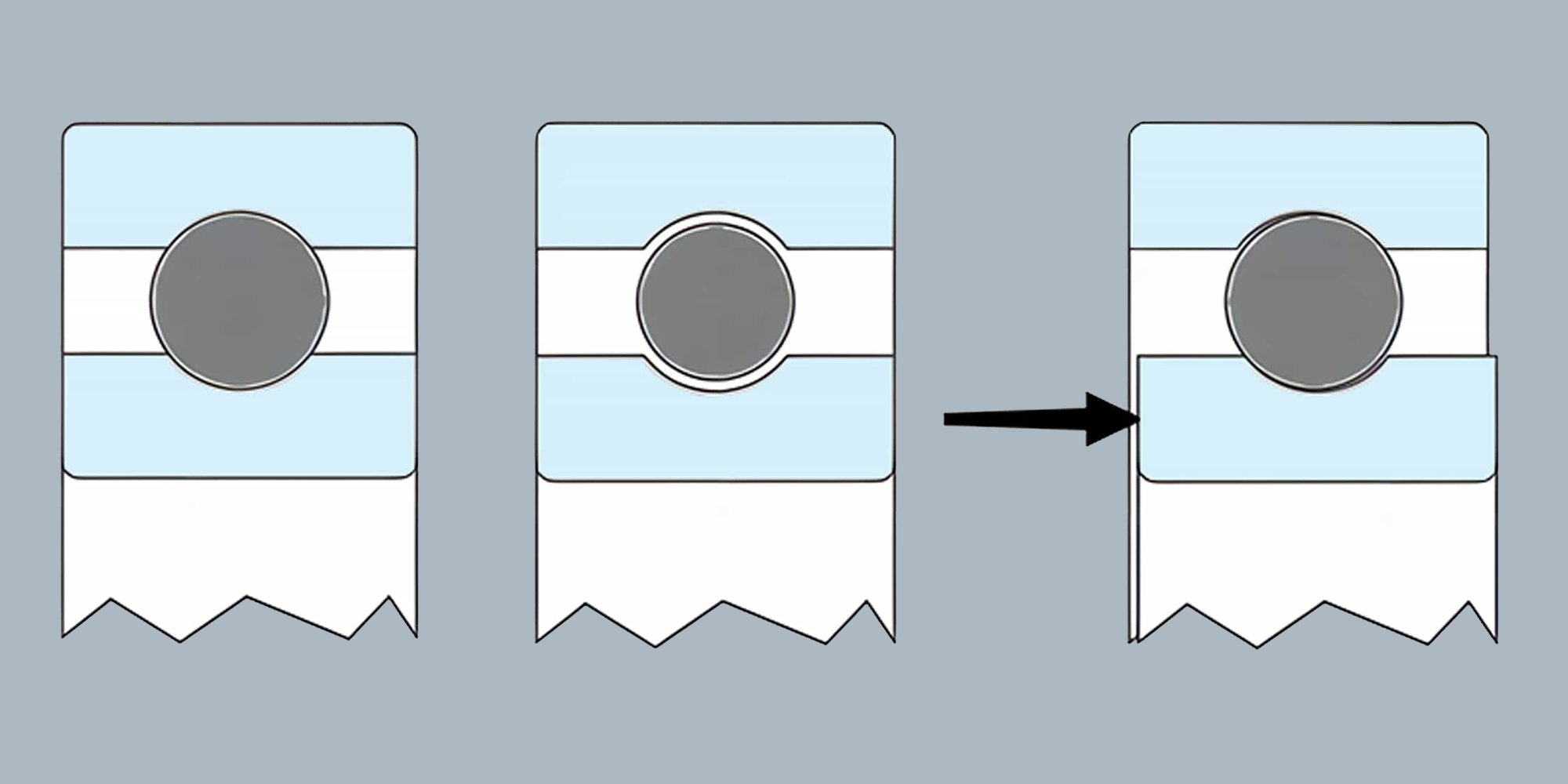

Suffixes, signify different designs or variants that deviate from the original or current basic design. For instance, Shielded and Sealed Bearings have different suffixes.

For “6206 LLB”, “LLB” stands for a bearing with non-contact rubber seals.

The following table presents some common bearing suffixes for seals or shields.

|

Suffix |

Description |

|

RS |

with rubber seal on one side, one side open |

|

2 RS |

with rubber seal on both sides |

|

Z |

with a metal seal on one side, one side open |

|

2 Z / ZZ |

with a metal seal on both sides |

|

V |

One side Non-Contact Seal |

|

VV |

Both Sides Non-Contact Seal |

|

DDU |

Both sides Contact Seals |

Different brands have different expanded suffixes.

In terms of NTN, please see the table below.

| Suffix | Description |

|---|---|

| ZA, ZZA | Removable steel shield(s) |

| ZA1, ZZA1 | Removable stainless steel shield(s) |

| Z1, ZZ1 | Stainless steel shield(s) |

| LB, LLB | Non-contact rubber seal(s) |

| LU, LLU | Contact rubber seal(s) |

| SA, SSA | Non-contact nylon seal(s) |

For SKF, see the following table.

| Suffix | Description |

|---|---|

| -RS1, -2RS1 | Contact seal, NBR, on one or both sides |

| -RS2, -2RS2 | Contact seal, FKM, on one or both sides |

| -RSH, -2RSH | Contact seal, NBR, on one or both sides |

| -RSH2, -2RSH2 | Contact seal, FKM, on one or both sides |

| -RSL, -2RSL | Low-friction seal, NBR, on one or both sides |

| -RST, -2RST | Low-friction seal, NBR, on one or both sides |

| -RZ, -2RZ | Non-contact seal, NBR, on one or both sides |

| -ZNBR | Shield on one side, snap ring groove in the outer ring, with snap ring on the same side as the shield |

| -ZNR | Shield on one side, snap ring groove in the outer ring, with snap ring on the opposite side of the shield |

| -ZZNR | Shield on both sides, snap ring groove in the outer ring, with snap ring |

| -ZZS | Shield on both sides, held in place by a retaining ring |

Besides seals or shields, there are other suffixes, such as cage design, materials, heat treatment, accuracy, clearance, preload, quiet running, stabilization, lubrication, as well as other special specifications.

Bearings are crucial components in the mechanical world, helping rotating equipment run smoothly and efficiently. Preloading a bearing is an...

Importance of Bearings in Mechanical Systems Bearings are crucial for smooth and efficient motion in mechanical systems, while reducing friction,...

Bearing failures can be a major headache for any facility, causing increased downtime, high-maintenance costs, missed deliveries, loss of revenue...