Slewing Bearings: How to Ensure Dimensional Accuracy

Slewing bearings are critical components in machinery, designed to manage axial loads, radial loads, and moment loads, ensuring stable operation in...

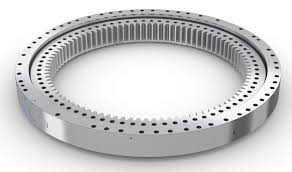

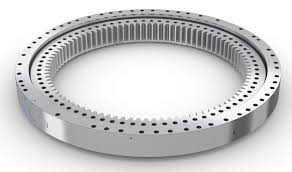

We call slewing ring bearings, turntable bearings or slew ring bearings. They are large-diameter bearings used in heavy-duty jobs like cranes, excavators, and tunnel machines. They handle heavy loads, including radial and tilting moment loading, and help things move smoothly in all directions.

They're super important for keeping large machines running well in industries like construction, mining, and even in aerospace systems.

Taking good care of these parts and doing regular maintenance is crucial to make them last longer.

To get the platform ready for slewing ring bearings, make sure the surface is strong and smooth. Machining the platform to required specs is crucial. This helps hold the bearing well and keeps everything lined up, avoiding problems later and making the bearing last longer.

To align mounting holes accurately for slewing bearings, follow these steps:

If the alignment is not proper, the bearing won't carry weight evenly. This can make it wear out fast and not last long. When you line everything up just right, the rolling element works its best and lasts longer.

To tighten mounting bolts on slewing ring bearings, use the diagonal method. Start at the center and work outwards, crisscrossing. Follow torque specs closely—too tight or loose can damage the bearing. Proper torque ensures the bearings work stably and safely.

Soft areas on slewing bearings are spots with less material or lower hardness.

Put these in parts that are without much load and frequent use to reduce stress and make the bearings last longer.

Slewing ring bearings require high-quality, heavy-duty, extreme-pressure grease. Choose the right type based on the supplier's advice.

Use the recommended lubricant. This can prevent bearing failures and costly repairs.

For slewing ring bearings, lubricate every 100 hours for slow equipment. And lubricate daily or every eight hours for fast-moving ones.

Add grease until old grease purges out. Check purged grease for grit or metal chips to ensure it’s clean. Oil them properly and frequently to ensure the bearings work well.

Bearing and gear lubrication differ. Bearings need thick grease put on at regular intervals. For slow machines, do it every 100 hours. For fast ones, do it every day.

Gears need oiling every eight hours on slow machines. On fast ones that run all the time, oil them even more often.

Use a little bit at the mesh point to make sure it's lubed up and doesn't wear out.

To keep slewing ring bearings well-lubed, use grease nipples to put thick grease all around the bearing. Automatic systems can help spread grease evenly too. Push out old grease to get rid of dirt, so the bearing works well and lasts longer.

Torque checks on slewing ring bearing bolts are crucial. Perform them often in harsh conditions. In high-vibration or shock-prone environments, check torque more frequently—maybe monthly—to ensure bolts stay tight and safe.

Bolts can stretch slowly over time, especially when it's hot. This is bolt creep. It makes the bolts less tight.

To find it, check the length and tightness of bolts often. Fix it by tightening the bolts again or putting in new ones if needed, especially in hot conditions.

Using the right torque is super important. Always follow what the maker says. If bolts are too loose or too tight, it can mess up your equipment and even break the bearings. This is not just about how well things work, but also about keeping everyone safe.

To inspect seals on slewing ring bearings, look closely at them regularly. Check for any cracks, signs of wear, or leaks. These can let dirt in and cause problems. If you see any damage, fix or replace the seals right away.

If seals on slewing ring bearings look damaged—like they have cracks, are worn, or are leaking—replace them right away. Bad seals can let dirt in and let lubricant out, which can mess up the bearing and make it wear out faster.

To check for play in slewing ring bearings, use a dial indicator. Measure how much the bearing moves when you apply a load. More play means the bearing is wearing out, which can make machinery less precise and sturdy. Fix it to keep things running smoothly.

Grinding, popping, or clicking noises from slewing bearings might mean not enough lubrication, too much wear, or loose bolts.

If you hear these noises, check the lubrication, tighten the bolts, and look for metal pieces in the grease.

If a slewing ring bearing is hard to turn or has tight spots, it might be wearing unevenly.

To fix this, check the load distribution, make sure the bolts are tight, and add more lubricant if needed.

Checking purged grease for metal chips or debris is crucial as it can indicate bearing wear or damage.

To keep dirt out, clean around the bearing often, use good seals, and always grease it correctly.

If you spot any debris, figure out its source and quickly fix any related problems.

Don't overload slewing ring bearings; stick to their rated limits. Overloading can damage them, causing fractures. Long-term overloads can ruin the bearing, so always follow load guidelines to keep them in good shape.

A clean environment is key to preventing dirt in slewing bearings. In outdoor or harsh settings, use protective covers and seals. Regularly clean around the bearings and check for debris to maintain performance and longer service life.

Extreme hot or cold temperatures can have bad effect on slewing ring bearings' performance and make them last not as long.

To keep them working well, use special lubes that can resist heat, wrap them up if it's too cold, and keep an eye on the temperature they work in.

Don't expose them to heat or cold extremes for too long.

We need a good maintenance plan to take good care of slewing ring bearings. This means checking them often, oiling them right, making sure bolts are tight, and keeping seals in good shape.

Schedule these tasks based on usage and environment. This way, you can make sure things work better and don't fail.

We need to train maintenance staff well for maintaining of slewing ring bearings. They need to learn about greasing, how tight to make bolts, checking seals, and fixing problems. Use guides from the bearing manufacturers and hands-on training to ensure staff are competent at it.

Keep detailed records of all slewing ring bearing maintenance. This helps track what you have done and spot trends or recurring issues. This makes it easier to fix problems early and plan future maintenance.

To see if slewing ring bearings are worn or damaged, check them regularly for wobble, strange noises, and visible defects. Use tools to measure gaps. Checking them regularly helps you know if they need repairs, so they don't break in an unexpected manner.

Fixing slewing ring bearings means smoothing rough spots and swapping out broken parts. Use special tools and methods to make sure the fixes work perfectly, keeping the bearings running smoothly and dependably.

Fixing up old slewing ring bearings usually costs less than getting new ones. It saves money and time. You can repair them at a lost less than half of what new ones cost, especially if you do it before they break.

This extends bearing life and reduces downtime.

Put the bearings in right, oil them a lot, check the bolts often, and keep an eye on the seals. This helps the slewing ring bearings last longer and work better.

Join with LILY Bearing for top-notch care and repairs. We help things run smooth and cut downtime. Trust us for precision and steady service.

Slewing bearings are critical components in machinery, designed to manage axial loads, radial loads, and moment loads, ensuring stable operation in...

Acting as the key "hinges" in large machines like cranes and excavators, slewing ring bearings enabled them to rotate smoothly and with precision in...

Slewing bearings are important parts of renewable energy systems, like wind turbines and solar trackers. They help these systems rotate smoothly and...