Are Ceramic Bearings Worth It in Bike Wheels?

Ceramic bearings reduce friction in cycling parts like wheels, bottom brackets, and hubs. This provides smoother and more efficient motion. Ceramic...

Curious about maintaining ceramic bearings? Questions like “What makes ceramic bearings better?”, "What can I use to clean ceramic bearings?" or "What's the best way to clean bearings?" and "Are ceramic bearings self-lubricating?" are common. Dive into our guide on “How to Clean Ceramic Bearings” for all the answers and expert tips on keeping your bearings in top shape.

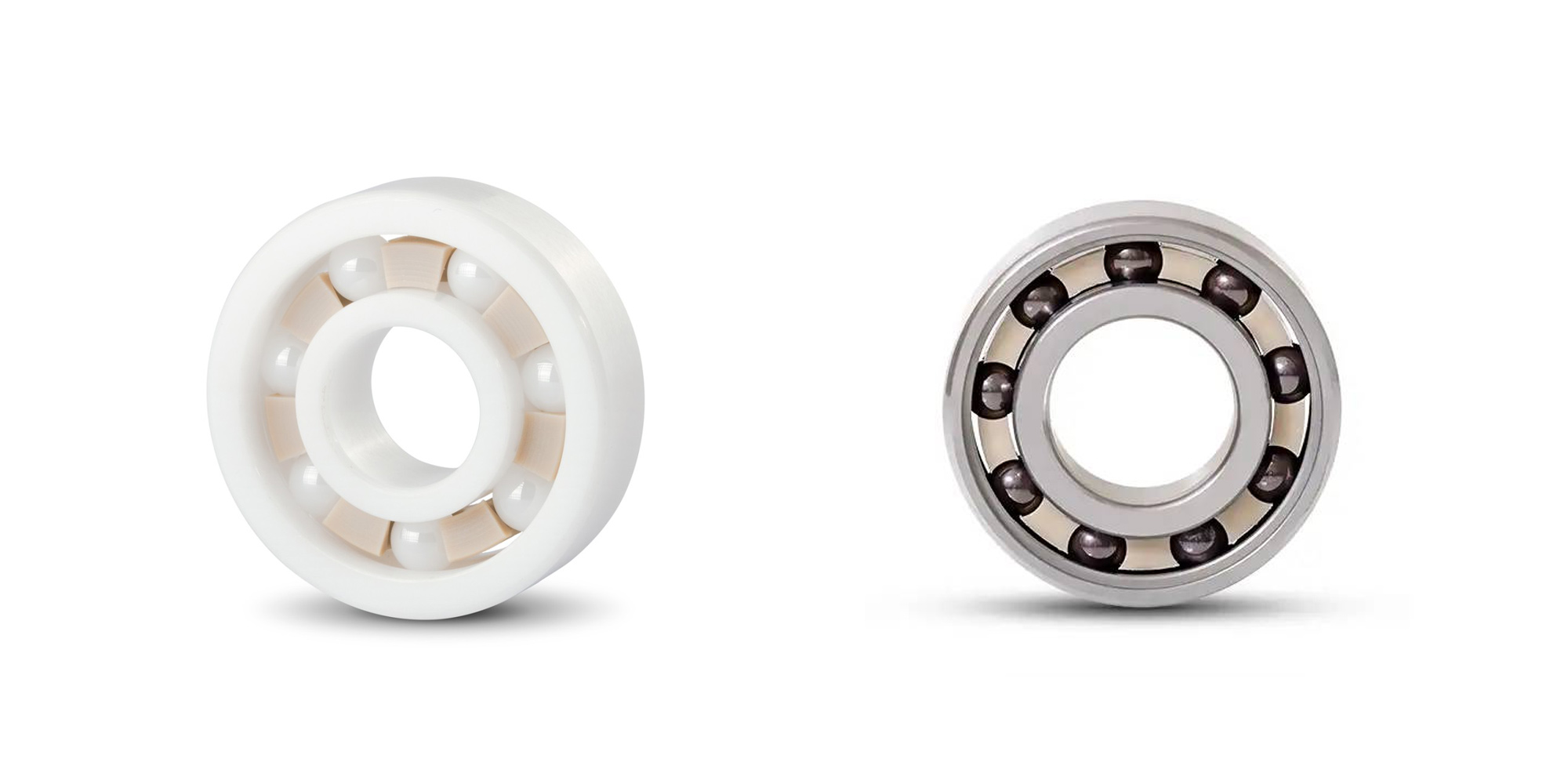

Ceramic bearings represent a significant advancement in bearing technology, offering superior performance under conditions where traditional steel bearings might falter. They come in two main types: Full Ceramic Bearings and Hybrid Ceramic Bearings. Each type serves distinct purposes across various industries, from aerospace to sports equipment, due to their unique properties and benefits.

Full Ceramic Bearings are constructed entirely from ceramic material, both the balls and the races. This construction makes them exceptionally resistant to bearing wear and corrosion, capable of operating in environments that are hostile to steel bearings. The most commonly used ceramics in these bearings are silicon nitride (Si3N4) and zirconium dioxide (ZrO2), each offering specific advantages such as reduced density, high hardness, and minimal thermal expansion.

Please click here to know more about Si3N4 ceramic bearings!

Full ceramic bearings are suited for extreme conditions, including high-speed operations in corrosive environments, vacuum applications, and high-temperature scenarios.

Hybrid Ceramic Bearings combine steel races with ceramic balls which are mostly silicon nitride balls. This design harnesses the low weight and high hardness of ceramic balls to reduce friction and wear, while steel races provide robustness and load-bearing capacity. Hybrid bearings are typically used in applications that demand high speeds, high precision, and increased durability without the full cost of complete ceramic solutions.

Please click here to learn the guide to Si3N4 balls!

Ideal for high-speed machinery, precision instruments, and applications where a balance between performance and cost is necessary.

|

Feature |

Full Ceramic Bearings |

Hybrid Ceramic Bearings |

|

Material |

Ceramic balls and races |

Ceramic balls, steel races |

|

Corrosion Resistance |

Excellent |

Good |

|

Temperature Resistance |

Very High |

High |

|

Magnetic Properties |

Non-magnetic |

Steel races may be magnetic |

|

Electrical Insulation |

Yes |

Steel races conduct electricity |

|

Weight |

Lighter |

Heavier than full ceramic, lighter than steel |

|

Cost |

Higher |

Moderate |

|

Application |

Extreme environments |

High-speed, precision applications with cost considerations |

Full ceramic bearings, known for their exceptional durability and resistance to harsh conditions, require minimal maintenance. Nonetheless, periodic cleaning can help preserve their optimal functionality and extend their lifespan. Here’s how to efficiently clean and maintain your full ceramic bearings without causing damage:

Although full ceramic bearings operate efficiently without lubrication due to their self-lubricating properties, in some instances, applying a light ceramic-compatible lubricant can further reduce friction and protect against wear. If you choose to lubricate, apply a minimal amount, ensuring it is evenly distributed across the bearing.

Once the bearings are dry (and lubricated if applicable), reinstall them according to the original assembly configuration. Correct installation is vital to avoid undue stress or misalignment that could affect performance.

Hybrid ceramic bearings, blending ceramic balls with metal rings, strike a balance between durability and performance. Unlike their full ceramic counterparts, these bearings may require lubrication, particularly in high-speed applications. Here's a streamlined approach to cleaning and maintaining your hybrid ceramic bearings for optimal performance.

Safety First: Wear protective gloves and eyewear to prevent any injuries.

Tools You Need:

Step 1: Identify Closure Type: Hybrid ceramic bearings come with either circlip retained shields or rubber seals. Knowing which one you have determines how you'll access the bearing for cleaning.

Step 2: Removing the Closure:

Step 3: Soaking

Step 4: Scrubbing

Step 5: Rinsing

Step 6: Drying

Dry the bearings and components completely using a clean, lint-free cloth or paper towels. Compressed air can be used to blow out any remaining moisture, especially from hard-to-reach areas within the bearing.

Step 7: Inspection

Inspect the bearings for any signs of wear or damage. Check the smoothness of the raceways and ensure there's no pitting or cracking.

Once clean and dry, and if your inspection doesn't reveal any issues, it’s time to relubricate:

Carefully replace the shields or seals, ensuring they fit snugly without forcing them. If your bearing uses a circlip, gently press it back into its groove in the outer raceway.

Spin the hybrid ceramic bearings by hand or within their assembly to ensure they move freely without noise or resistance.

By following these detailed steps, you can ensure your hybrid ceramic bearings remain in peak condition, offering the performance and longevity expected from such high-quality components.

Picking the right ceramic bearing for tough conditions? Get advice tailored to your needs. While DIY maintenance is popular among cyclists and skateboarders, industrial settings and large-scale operations should consult a professional.

Need more tips on selecting and caring for ceramic bearings? Reach out to a specialist at LILY Bearing. We’re seasoned in providing all sorts of ceramic bearings for challenging industries. Talk to our experts today.

Knowing how to clean bearings, whether full ceramic or hybrid, is key to their durability and peak function. Regular upkeep and correct cleaning methods will prolong your ceramic bearings' life, ensuring smooth operation. Follow this blog's advice to keep your bearings in prime shape, saving you both time and money.

Ceramic bearings reduce friction in cycling parts like wheels, bottom brackets, and hubs. This provides smoother and more efficient motion. Ceramic...

For the sake of environmental protection, the electric vehicle industry has been growing rapidly in recent years. The electric vehicles in China...

Ceramic bearings are a type of bearing that uses ceramic materials either partially or fully. They are an alternative to traditional steel bearings....