How to Properly Install McGill Cam Followers

McGill cam followers are important parts that help machines move precisely and reliably. They convert rotational motion into linear motion. Their...

Selecting the right cam follower is crucial for the optimal performance and longevity of your mechanical systems. This blog will help you easily understand the important factors to consider, choices of materials and design, and a straightforward way to select the best options for top performance. We’ll also provide case studies and examples, and introduce some well-known brands in the industry.

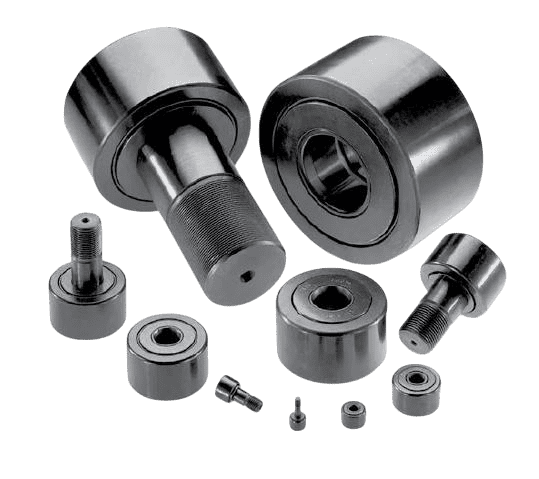

A cam follower, also known as a roller bearing, is a special kind of bearing. It follows the shape of a cam to change spinning movement into straight-line movement. They play a critical role in reducing friction and ensuring smooth operation in wide ranges of mechanical systems.

Cam followers include several key components:

Picking a cam follower that can handle the right amount of weight is key to avoid breakdowns and make your equipment last longer.

The operating speed of your motion systems significantly impacts the selection of cam followers. Ball bearing options might be best for high-speed applications.

Select cam followers designed to withstand your operating environment, considering factors like temperature and exposure to dirt.

The table below will make it easy for you to compare the various material options for cam followers, showing their strengths, weaknesses, and when they're best used:

|

Material |

Strengths |

Weaknesses |

Best For |

|

Carbon Steel |

High strength and durability, cost-effective |

Susceptible to corrosion if not properly treated or lubricated |

General-purpose applications where cost is significant, and environmental conditions are mild |

|

Stainless Steel |

Excellent corrosion resistance, good strength, and durability |

More expensive than carbon steel |

Corrosive environments, such as food processing or outdoor equipment |

|

Tool Steel |

High hardness, excellent wear resistance, withstands high temperatures |

More expensive, may require special handling or treatment |

High-load and high-wear applications, such as manufacturing machinery |

|

Ceramic |

Extremely high hardness, excellent wear resistance, high-temperature operation, non-magnetic, corrosion-resistant |

Brittle, more expensive |

High-speed applications, medical devices, environments where magnetic properties are a concern |

|

Composite Materials |

Lightweight, corrosion-resistant, can be tailored for specific properties |

Generally less durable than metal options, can be more expensive |

Applications requiring a balance of weight and performance, such as aerospace or specialized machinery |

|

Plastic |

Lightweight, corrosion-resistant, cost-effective |

Lower strength and wear resistance compared to metals |

Low-load applications where corrosion resistance and weight are more critical than strength |

Consider design features that can enhance performance, such as:

Figure Out Load Needs

Start by figuring out how heavy a load your cam follower needs to support. Picking one that matches your load requirements prevents wear and breakdown, saving on replacements.

Check Speed and Movement

Consider how fast and in what way your cam follower will move. For high-speed or continuous motion, choose a design that reduces friction and heat.

Think About the Setting

Where will the cam follower operate? Harsh conditions like extreme temperatures or exposure to chemicals call for durable materials like stainless steel or special coatings.

Match the specifications of the cam follower with your needs. Check their weight handling, speed limits, material fit, and special design traits to ensure they meet your demands.

Ask for help from experts and get technical support from the makers or sellers. They can offer helpful tips and suggest the best options for your particular needs.

In every scenario described below, cam followers are crucial. This is especially true for those with crowned outer rings, which are made for carrying loads and need to be correctly positioned on the cam's side.

In the industry, several brands are well-recognized for their quality and reliability in manufacturing cam followers.

Choosing the right cam follower is vital for the performance and longevity of your mechanical systems. Please take a close look at the important factors we've talked about—like load capacity, speed, environmental conditions, material, and design features—to make sure you get the best performance. Also recommended is to consult a professional supplier. For more information or tailored advice and solutions about bearings for your application, contact us today.

McGill cam followers are important parts that help machines move precisely and reliably. They convert rotational motion into linear motion. Their...

In the vast expanse of mechanical engineering, few mechanisms are as indispensable as the cam and its accompanying cam follower. They not only...

In the industrial sector, machines that work well all the time are essential for good performance and safety. McGill cam followers are just a crucial...