How to Select the Best High Temperature Bearings?

Bearings are essential components in machines, allowing them to rotate smoothly and efficiently. In industries like steel production, kilns, and gas...

Bearings are important parts in machines. They help reduce friction and keep everything running smoothly. Industries like automotive, aerospace, and manufacturing rely on bearings. Without good bearings, machines would break down more often and need more repairs.

In this blog, we will discuss how to choose the best bearing manufacturer for your needs. We will cover key factors to consider and how to make an informed decision.

The quality of bearings is important. Good bearings reduce friction, make machines last longer, and prevent breakdowns. To make sure the bearings are good, check if the manufacturer has international certifications.

Look for certifications such as ISO, ABEC, JIS, or DIN. These certifications indicate that the manufacturer adheres to recognized international quality standards. These certifications show that the bearing manufacturer follows strict quality standards.

Bearing manufacturers like LILY Bearing follow these standards. This ensures they provide high-quality products.

Choose a bearing manufacturer with a broad product range. A good bearing supplier should offer different types of bearings. This includes ball bearings, roller bearings, taper roller bearings, and deep groove bearings.

Customization options for bearings offer several important benefits:

A high-temperature bearing can be made with special materials to withstand heat in engines or ovens.

A tapered roller bearing can be customized to carry heavy radial and axial loads in machinery.

Corrosion-resistant bearings last longer in harsh environments like those found in marine industries.

Custom-fit bearings in conveyor systems can prevent delays by ensuring smooth operation.

Custom bearings in specialized machinery can lower maintenance costs by preventing frequent breakdowns.

LILY Bearing offers a wide range of bearings and provides custom solutions for different needs. For example, they can create high-temperature bearings or corrosion-resistant bearings for tough environments. These custom bearings ensure reliable performance in industries like automotive, aerospace, and marine.

A bearing manufacturer’s production ability is important. Look at their equipment, facilities, and how efficient they are. New technology can make bearings more precise, stronger, and longer-lasting.

Top bearing manufacturers invest in research and use advanced materials to make better bearings. Ongoing improvements make bearings perform well and last longer, even in tough conditions.

Experience is crucial when choosing a bearing manufacturer. A company with years of experience is more likely to offer high-quality products and expert support. They are also better equipped to handle complex requirements.

Bearing manufacturers like LILY Bearing are known for delivering high-quality bearings. Their experience makes them a trusted partner for any business.

Customer support and technical expertise are key factors to consider. A bearing manufacturer with knowledgeable engineers can guide you in selecting the best bearings for your application. They should also offer troubleshooting and after-sales support.

LILY Bearing, for example, offers technical assistance to help you choose the right bearing and ensure smooth installation.

On-time delivery is vital to avoid production delays. If bearings are not delivered on time, it can cause unexpected downtime. This can disrupt your entire production schedule and lead to costly delays.

Bearing manufacturers with a strong global distribution network are better equipped to handle these challenges. They can quickly ship bearings to various locations, ensuring that you always have access to the products you need. This reduces the risk of waiting for parts and keeps your operations running smoothly.

LILY Bearing is a great example of a company with a reliable global logistics system. They have optimized their supply chain to ensure quick and on-time delivery to customers all around the world. With LILY Bearing, you can trust that your bearings will arrive when needed. This helps prevent unnecessary delays and keeps your production lines moving efficiently.

Cost is an important factor when selecting a bearing manufacturer, but it shouldn’t be your only consideration. Focusing only on price can lead to choosing lower-quality bearings, which can result in higher costs over time.

The Total Cost of Ownership (TCO) includes not just the initial purchase price. It also covers the costs of durability, maintenance, and replacement over time. Cheaper bearings may need more frequent replacements or repairs, adding to long-term costs.

Choosing a bearing manufacturer that focuses on quality gives better long-term value. High-quality bearings reduce downtime. They improve machine efficiency and lower maintenance costs. This leads to greater savings in the future.

Sustainability is more important in the bearing industry. Bearing manufacturers focus on eco-friendly practices. This helps reduce environmental impact. They recycle, cut carbon emissions, and make energy-efficient products.

LILY Bearing is dedicated to being sustainable. They work hard to reduce the environmental impact of their products. This includes using eco-friendly materials and greener manufacturing methods.

They also focus on reducing waste, lowering carbon emissions, and saving energy in production. It's goal is to make high-quality bearings while supporting a cleaner, greener future.

LILY Bearing is a new company that makes high-quality bearings for many industries. They offer a wide range of bearings to meet different needs, ensuring reliability and performance. Whether for cars, airplanes, or factories, we provides solutions that are precise and reliable.

It offers many types of bearings to fit different needs. They can customize bearings for specific requirements. Their products meet high-quality standards for reliability.

This company also provides great customer support and helps you choose the right bearings. With reliable delivery, they make sure your bearings arrive on time.

LILY Bearing focuses on innovation and sustainability, making them a great partner for your bearing needs. They keep improving their products and processes, while also working to reduce their environmental impact.

When choosing a bearing manufacturer, focus on key factors. These include quality, support, customization, and how well they meet your needs. Finding a bearing manufacturer that offers long-term value is important. They should deliver bearing solutions that work for you.

LILY Bearing is a great choice, known for their commitment to quality and reliability. They offer a wide range of bearings and customized solutions to meet your needs.

Contact us today to learn how they can provide the perfect bearings for your business.

Bearings are essential components in machines, allowing them to rotate smoothly and efficiently. In industries like steel production, kilns, and gas...

Extending the life of ball bearings is important for improving efficiency, reducing downtime, and controlling costs. By reducing the need for...

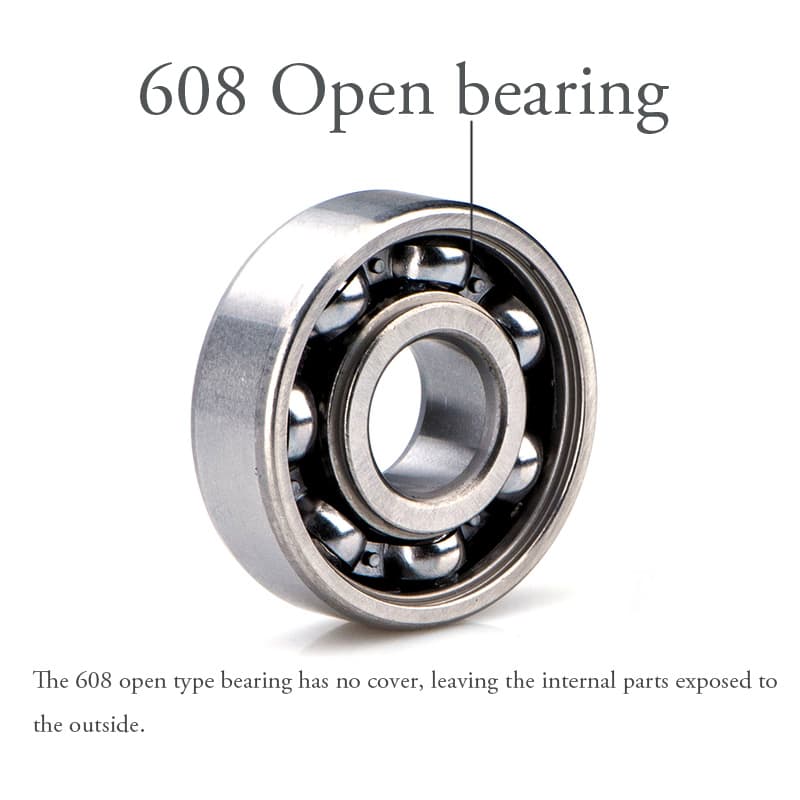

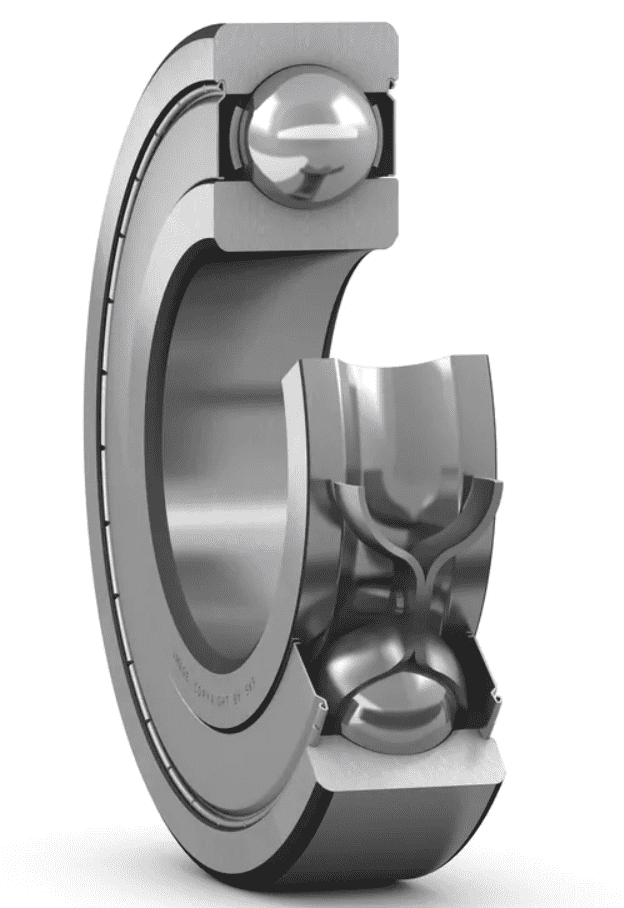

Introduction to Ball Bearings Ball bearings are parts that help things move more smoothly by reducing friction between moving parts. They have two...