How Do I Choose a Slewing Bearing?

Slewing bearings, also known as slew bearing or slewing ring bearings, facilitate pivotal movement in machinery, handling axial, radial, and moment...

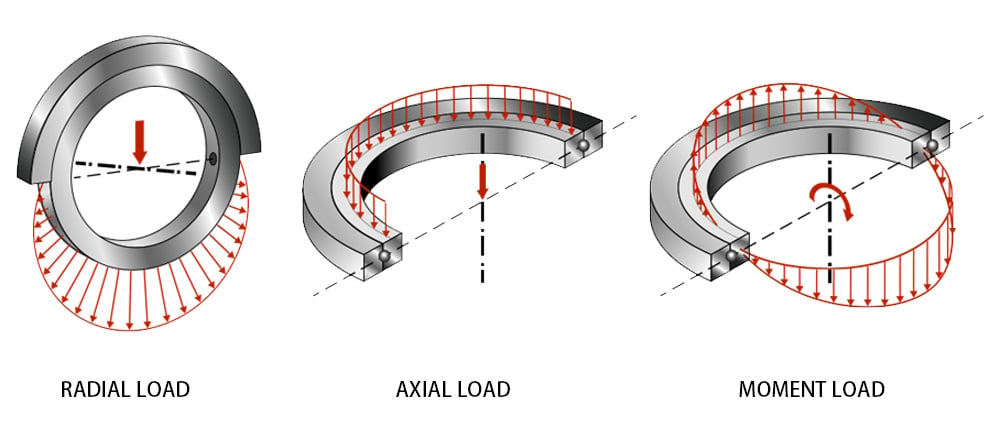

slewing ring bearings, or slewing bearings, are a fundamental component in numerous industrial machines, particularly in the renewable energy sector. These specialized bearings are designed to accommodate axial, radial, and moment loads in a compact footprint. This design allows for the simultaneous handling of vertical and horizontal forces, a crucial attribute for heavy-duty applications like wind turbines and underwater energy systems.

Slewing bearings function by facilitating rotational movement and bearing multidirectional loads in heavy-duty applications. Their design integrates two concentric rings with rolling elements between them, allowing them to support axial, radial, and moment loads efficiently. This structure ensures smooth rotation with minimal friction, crucial for applications that demand precision and durability.

Lily Bearing has established itself as a key player in the global bearing industry. Renowned for their premium-quality slewing bearings, the company has earned recognition for its innovative solutions tailored to the clean energy sector. Their slewing bearings are not only efficient but also customized to endure the demanding conditions of underwater and offshore applications.

In the underwater clean energy industry, the operating environment presents unique challenges. The exposure of slewing bearings to harsh marine conditions, particularly seawater, necessitates robust anti-corrosion measures. Traditional sealing methods, while providing some protection, often fall short in the face of aggressive marine corrosion.

To tackle these challenges, Lily Bearing has developed a suite of cutting-edge anti-corrosion technologies:

Among these technologies, Lily Bearing has specifically chosen cathodic protection for its slewing bearings. This method involves attaching more reactive metals like zinc or aluminum to the bearings. These metals preferentially corrode, protecting the primary metal from oxidation and decay. This approach is particularly effective for slewing bearings used in offshore wind turbines, where they are submerged or partially submerged in seawater.

The use of cathodic protection significantly reduces maintenance needs for slewing bearings in challenging underwater environments. This technology promises to extend the operational life of the bearings, potentially doubling the standard six-month maintenance-free period. This advancement is not just a technical triumph but also an economic benefit for clients in the clean energy sector.

Lily Bearing's dedication to client satisfaction extends beyond product quality. Their technical team provides comprehensive support, from selecting the appropriate bearing design to customizing installation solutions. This includes advising on through-hole specifications for mounting and explaining the impact of surface finishes on bearing performance. Their proactive approach to problem-solving and client collaboration has led to high client satisfaction and extended product lifespans.

Lily Bearing's commitment to innovation, quality, and customer service has positioned them as a leader in the bearing industry. Their slewing bearings, equipped with advanced anti-corrosion technology, are not only enhancing the performance of clean energy applications but also setting new standards in durability and reliability. By continuously evolving to meet the specific needs of the clean energy sector, Lily Bearing is playing a pivotal role in driving the industry forward.

Slewing bearings, also known as slew bearing or slewing ring bearings, facilitate pivotal movement in machinery, handling axial, radial, and moment...

Importance of Bearings in Mechanical Systems Bearings are crucial for smooth and efficient motion in mechanical systems, while reducing friction,...

Bearings ensure the smooth operation and long life of mechanical components. Kaydon Bearings are known for their high performance and versatility....