Bearing Seal Types & How to Select the Best

Whether you’re working with roller bearings, stainless steel ball bearings, or spherical roller bearings, bearing seals play an essential role in...

4 min read

Robert

:

Aug 21, 2025 2:59:05 AM

Robert

:

Aug 21, 2025 2:59:05 AM

Table of Contents

Discover the secret to flawless machinery performance: "How Much Grease to Put in Bearings".

The right amount can mean the difference between efficiency and costly repairs.

Engineers regularly design custom bearings for extreme longevity, and below we that experience so you can keep your equipment running smoothly land lasting longer.

Grease plays a pivotal role in protecting bearings, acting as a barrier against contaminants while reducing friction and wear.

It essentially seals out dirt and moisture, which can damage the bearing surfaces, and helps dissipate heat generated during operation.

By thinking about these factors, you can make sure your bearings get just the right amount of grease—not too much and not too little—a rule of thumb for maintenance.

Ensuring your bearings are properly lubricated is key to their performance and longevity.

The amount of grease needed can vary significantly between different types of bearings.

Here’s a closer look at the recommended greasing guidelines for two common types:

For both bearing types, it’s essential to use the correct type of grease—such as bearing grease with the right additives and base oil—and apply the correct amount of grease according to these guidelines.

Doing so will help in achieving the optimal balance between lubrication and bearing efficiency, enhancing the performance and extending the lifespan of your bearings in various applications.

A widely accepted method for calculating grease volume is the SKF formula:

Gq = 0.114DB,

Where:

Gq = Quantity of grease in ounces

D = Bearing's outside diameter in inches

B = Width of the bearing in inches (or height for thrust bearings)

Based on this, another common guideline for determining grease amount is:

G =DB/10

Where:

D=the shaft diameter in inches

B=bearing width in inches

G=grease quantity in ounces

For a sealed bearing on a 3-inch diameter shaft that is 1 inch wide, you would need 0.3 ounces of grease.

For every inch of shaft diameter, use one stroke from a grease gun or zerk. Given the variation in grease guns, using 2 or 3 grams per inch might be more precise.

For a DIY approach, verify your gun's output by weighing 10 strokes on a scale to gauge the grease dispensed per stroke.

Detect proper bearing lubrication by the decrease in noise and increase in grease gun handle pressure.

At operational speed, noise drops with the first grease addition and stabilizes, but rises when the bearing is full—stop greasing then.

In the realm of high-speed machinery, the application of grease needs to be meticulously managed.

The primary aim is to minimize grease usage without compromising lubrication effectiveness.

This precise balance ensures that the machinery operates smoothly while avoiding the drag that excessive lubricant can cause.

Operations exposed to challenging environmental conditions necessitate a tailored approach to grease application.

Adjusting the volume of grease can significantly enhance the durability and reliability of machinery under such circumstances.

Benefits:

Professional attention to these lubrication strategies ensures that equipment operates efficiently, with reduced maintenance needs and increased resilience against operational challenges.

Overgreasing can lead to increased Power Consumption and Temperature.

More grease means more resistance, which makes the machinery work harder and get hotter. This can shorten the lifespan of your bearings.

While overgreasing is generally not recommended, in very specific conditions, like extremely harsh environments, a little extra grease might help protect the bearings from contaminants.

In general, over 80% of bearing failures are attributed to inadequate lubrication practices, where grease no longer provides sufficient protection.

Undergreasing comes with its own risks:

Choosing the right amount of grease is key for lubricating bearings effectively and keeping your machinery running well. Our guide helps you strike that balance, avoiding overheating or bearing wear and tear. For more tips and expert advice on "How Much Grease to Put in Bearings," check out our guide and keep your machinery running smoothly.

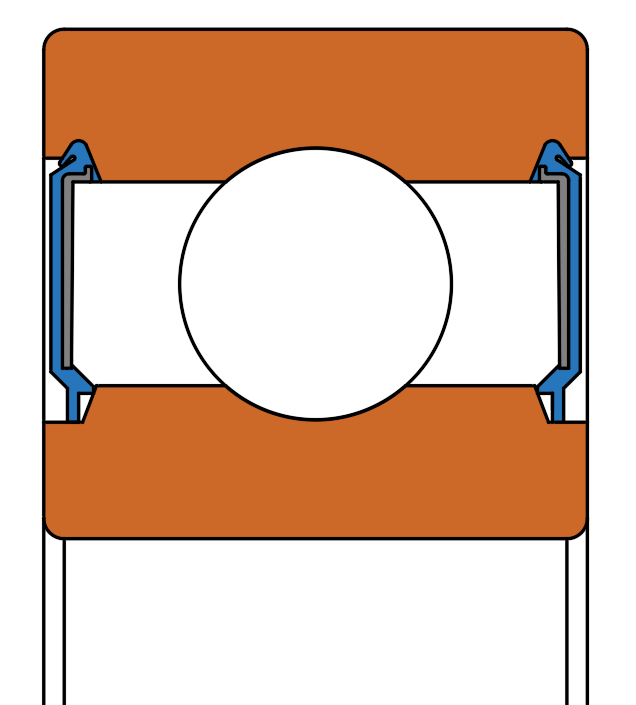

Whether you’re working with roller bearings, stainless steel ball bearings, or spherical roller bearings, bearing seals play an essential role in...

Why Bearing Lubrication is Important Effective bearing lubrication is crucial for the optimal performance and longevity of bearings. It's widely...

Proper lubrication is paramount for the optimal performance and extended lifespan of pillow block bearings. Without it, these critical components are...