Slewing Bearing and Jib Crane Bearing Guide

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...

Slewing bearings, sometimes called slewing rings, slewing ring bearings, or turntable bearings, play a key role in machines that need to spin accurately around a single center point.

In tough industrial settings, from big construction machines to high-tech medical tools, these bearings are the key to many machines, making sure they work smoothly and last a long time.

Check out this blog to find out how slewing bearings work and see where they're used in wide ranges of applications.

A slewing bearing, also known as a slew bearing, a slewing ring bearing or a slewing ring, is a large, robust bearing designed to support and allow smooth rotation in heavy machinery, such as cranes and wind turbines.

They make possible 360-degree movement around a central axis. It's really good at dealing with different kinds of forces all at the same time, like axial loads, a radial loads, and moment loads.

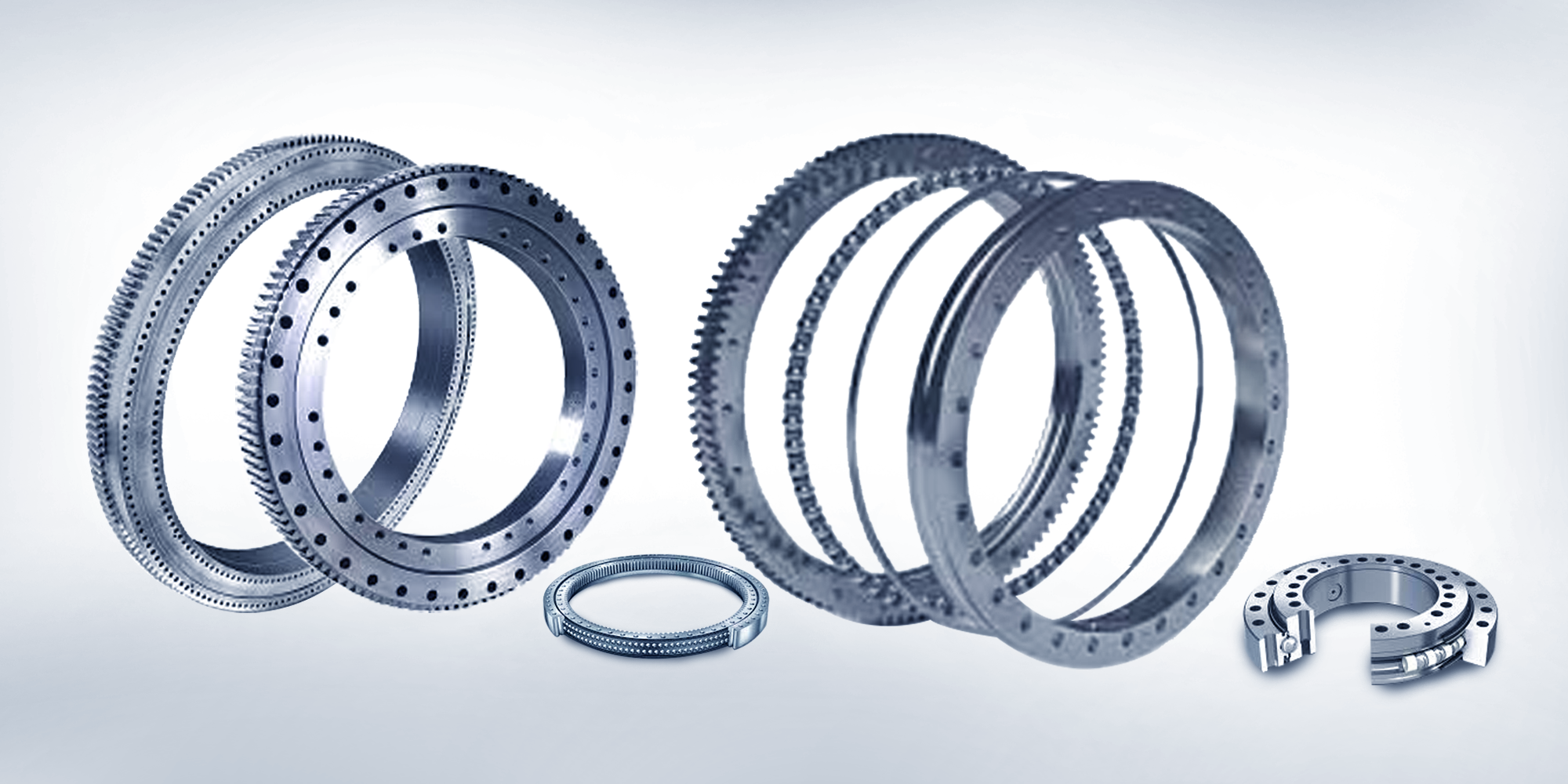

Fig 1 Structure of a Slewing Bearing

The design of a slewing bearing, also known as a slewing gear bearing or a turntable bearing, is smartly made to allow s and to hold seamless rotation and sustain significant load capacity.

Slewing bearings, sometimes called slew rings, turntable bearings, or slewing gears, are like the main support that enables heavy machinery rotate smoothly at a rational speed.

They're smartly made so that the inside part and the outside part can spin around each other.

This rotation is facilitated by their connection to different parts of the machinery, providing a wide range of motion up to 360 degrees.

The secret to how these bearings work so efficiently is in the rolling elements—either balls or rollers—that are carefully placed between the inside and outside rings.

These parts are super important in minimizing bearing friction.

This means the machine can spin around smoothly and easily, which makes it work more accurately and quickly.

Slewing bearings are made to be versatile, handling different kinds of loads—axial (thrust), radial, and moment (tilting) loads—all at the same time.

Their design spreads these loads evenly across the bearing parts, making them strong and reliable.

The bearing supports axial loads through the interaction of its rolling parts and raceways.

Radial loads are spread across the surface of these rolling parts.

Moment loads are evenly distributed due to the bearing's structure and the placement of its rolling elements.

This balanced distribution not only keeps the machinery steady but also helps the bearing and the equipment last longer.

Slewing bearings with gears, like slewing gears, come with a built-in gear system that gives them extra functionality—they can rotate with power.

is really useful when you need the bearing to be driven by an external motor or slew drive power source.

It helps in making controlled and precise movements, which is important for many types of machinery to work well.

Some designs also include an external gear that can be directly meshed with a drive mechanism, allowing for more efficient power transmission.

Slewing bearings come in various designs, each with its unique working mechanism.

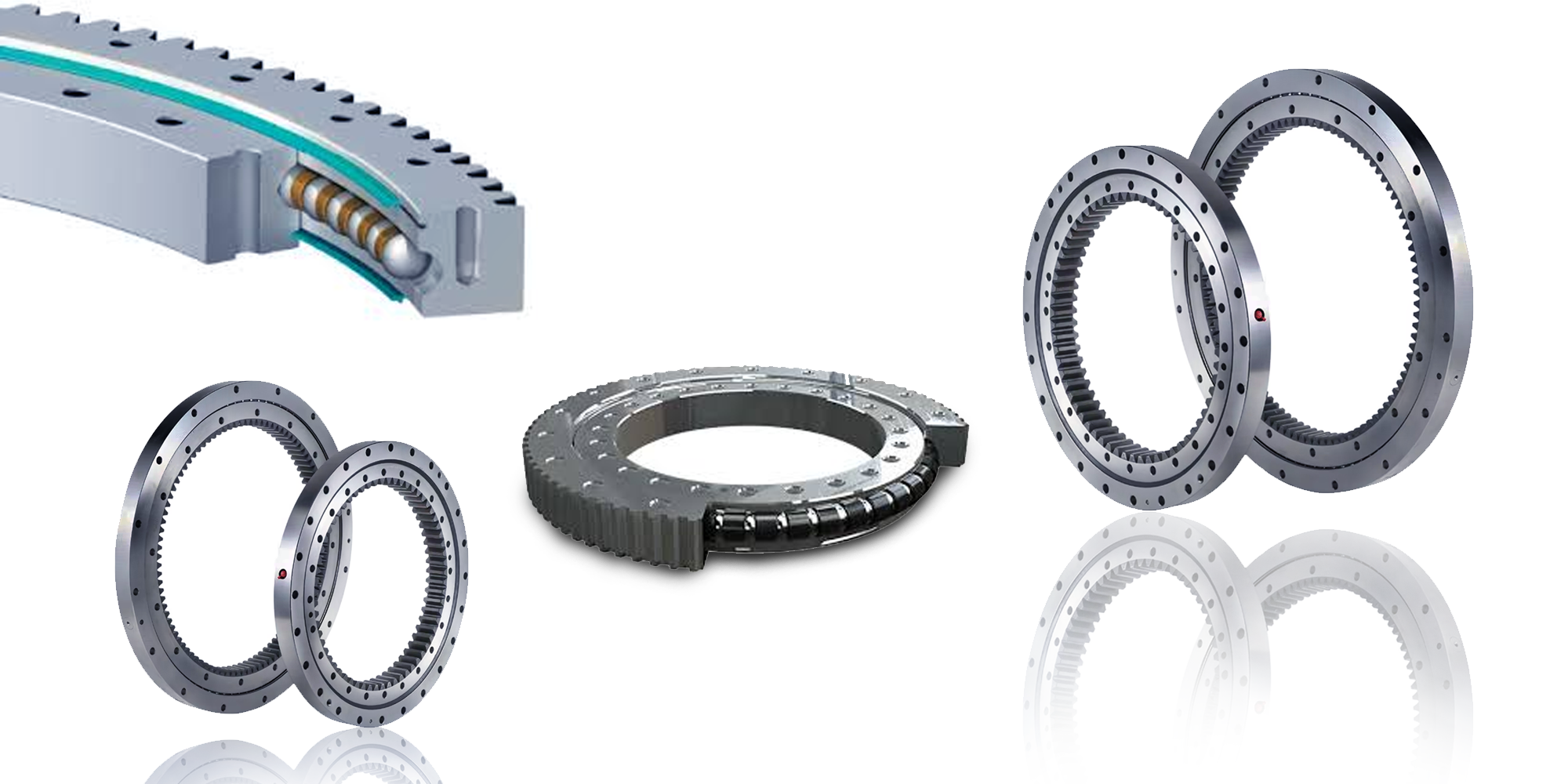

Four-point contact ball bearings feature a unique design where each ball contacts the raceway at four points.

This allows the ball slewing bearing to simultaneously handle axial, radial, and moment (tilting) loads efficiently.

The design optimally distributes loads, ensuring stability and minimizing stress points.

This makes it perfect for applications requiring multi-directional loads support, enhancing its adaptability across diverse industrial uses.

Fig 2 Four Point Contact Ball Bearing

Eight-point contact ball slewing ring bearings feature a dual-row ball design that engages the raceway at eight distinct points, ensuring enhanced contact and stability.

This design increases the bearing's ability to manage axial, radial, and moment loads by spreading them more uniformly over a greater number of contact points.

The result is increased load resistance, better stability, and improved service life, particularly in applications with complex loading conditions.

Fig 3 Eight Point Contact Ball Slewing Ring

Cross roller slewing ring bearings, or cross roller slewing bearings, have rollers arranged crosswise, with alternate rollers at right angles to one another.

This design achieves superior load distribution, with each roller capable of simultaneously supporting radial, axial, and moment loads from every direction.

The cross-roller configuration offers exceptional rigidity and stability, ideal for applications demanding heavy load capacity and precise motion control.

A cross roller slewing ring bearing have roller slew ring bearings have rollers set up in an X pattern, with rollers at 90-degree angles to each other.

This layout spreads out the load really well, so each roller can handle weight, push-pull forces, and twisting forces from all sides at the same time.

The X-shaped roller setup gives these bearings great strength and stability, making them perfect for jobs that need to handle heavy loads and need very precise control of movement.

The cross-roller setup gives great strength and steadiness, perfect for jobs that need to carry heavy and control movements precisely.

Fig 4 Cross Roller Slewing Ring

Three-row cross roller slewing ring bearings, or three-row cross roller slewing bearings, boast separate raceways for each row of rollers, enhancing load distribution.

This innovative cross roller slewing bearing design assigns each row the task of supporting distinct load types—axial, radial, and moment—separately, leading to a bearing that withstands considerably higher loads with enhanced stability and precision.

It's perfectly suited for heavy-duty tasks requiring sophisticated load management.

Fig 5 Three-Row Cross Roller Slewing Ring Bearing

Combined bearings use both balls and rollers to share the load.

The balls are great for handling straight-in-line loads, while the rollers are perfect for dealing with side loads and twisting forces.

By using both, the bearing can spread out all kinds of loads evenly, making the machine more stable, wearing less, and helping machines work better in all sorts of situations.

Fig 6 Combined Bearings (Ball and Roller)

Slewing bearings are found in many types of businesses because they're good at handling tough movements and heavy stuff without any trouble.

The blog guides you to understand what slewing bearings are and how they work.

Slewing bearings are essential for precise, single-axis rotation in heavy machinery.

They can handle axial loads, radial loads, and moment loads.

Their parts, including inner/outer rings, rolling elements, and optional gears, ensures smooth operation and load distribution.

Widely used in cranes, wind turbines, medical devices, and robotics, they enhance stability, reduce wear, and improve efficiency.

For all your slewing bearing needs, look no further than LILY Bearing, a slewing bearing manufacturer for products no worse than Kaydon bearings.

Slewing bearings are essential in heavy machinery like cranes. They allow jib cranes to function effectively with 360-degree movement for precise...

Crane slewing bearings are essential parts that let cranes make their full 360-degree turns. This ability is crucial for handling various lifting...

Slewing bearings, also known as slew bearing or slewing ring bearings, facilitate pivotal movement in machinery, handling axial, radial, and moment...