Understanding the Load Capacities of Kaydon Bearings

Bearings ensure the smooth operation and long life of mechanical components. Kaydon Bearings are known for their high performance and versatility....

Slewing bearings, also known as slew bearing or slewing ring bearings, facilitate pivotal movement in machinery, handling axial, radial, and moment loads simultaneously. They are essential for 360-degree movement in heavy machinery and precision equipment. The blog post "How Do I Choose a Slewing Bearing?" guides you in selecting the right bearing. It covers bearing types, structures, key factors like load capacity and rotational speed, and tips for sizing, material selection, installation, and maintenance.

A slewing bearing is a type of bearing designed to support and transmit high loads while allowing rotational movement.

| Type | Description |

| Four Point Contact Ball Slewing Ring Bearing | Balances axial, radial, and moment loads. |

| Eight Point Contact Ball Slewing Ring Bearing | Enhanced load capacity for heavy-duty use. |

| Cross Roller Slewing Ring Bearing | Supports all load types with high precision. |

| Three-Row Cross Roller Slewing Ring Bearing | Separates and increases load capacity. |

| Thrust Ball Slewing Rings | Specialized for high axial loads. |

| Combination Slewing Rings | Combines ball and roller for balanced support. |

| RealiSlim TT Turntable Bearings | Compact, ideal for space-limited applications. |

| Mating Pinions | Enables powered rotation. |

| Slewing Ring Bearings In Transport Vehicles | Provides smooth rotation and support for loads in transport applications. |

Slewing bearings, including slewing gear bearings, are essential in a wide variety of applications. Here's an overview of their key uses:

Evaluates bearing capacity, focusing on:

Verifies performance and safety:

Determine the equipment requirements, including:

Also, consider operational life, space constraints, and budget to ensure the slewing ring meets the machinery's specific needs.

Multiply the bearing forces by the service factor.

Service factors depend on the frequency of high vs. normal loads and the potential for extreme or impact loads. Customer specifications, finite element analysis (FEA), or regulations may override these factors.

If your application isn't in the following Table, use a similar one for initial sizing or consult the manufacturer.

| Application | Service Factor |

| Aerial Lift Devices | |

| - Aerial baskets, platforms, ladders | 1.00 |

| Conveyors | 1.00 |

| Cranes | |

| - Mobile (Loads Limited by Machine Stability): | |

| -- Normal Construction Duty (Tire Mounted) | 1.00 |

| -- Normal Construction Duty (Crawler Mounted) | 1.10 |

| -- Production Duty (Scrap/Ship Yards) | 1.25 |

| -- Forestry Handling (Logging) | 1.50 |

| -- Stacker Cranes (Includes Dynamic Forces as Loads) | 1.25 |

| - Pedestal or Tower (Loads Not Limited by Machine Stability): | |

| -- Loads Monitored by Safe Load Device | 1.25 |

| -- Applications with Sudden Impact Load | 1.50 |

| Excavators | |

| - Load Limited by Tipping | 1.25 |

| - Load Limited by Hydraulic Pressure Relief | 1.50 |

| Index and Turnstile Tables | |

| - Occasional Use with Intermittent Rotation | 1.00 |

| - Frequent Use with Intermittent Rotation | 1.25 |

| - Frequent Use with Intermittent Rotation and Impact | 1.50 |

| Industrial Manipulators and Robots | |

| - Occasional Service | 1.00 |

| - Frequent Service | 1.25 |

| Steering Gear (Must Include Dynamic and Shock Loads): | |

| - Pneumatic Tires | 1.25 |

| - Solid Tires | 1.50 |

If an integral gear is required, determine the required Gear Capacity.

Consider all conditions that may generate gear loads, such as:

Determine the Preferred Mounting Arrangement:

Examples of Basic Arrangements:

Fig 1

As shown by the through bolt arrangement in Fig 1, the pinion attaches to the outer ring, supporting the upper structure via the inner ring. A shroud with bolts covers the outer seal to prevent contamination in harsh conditions.

Fig 2

The upper structure, which includes the pinion, is supported by the inner ring via through bolts. Also an external shroud is in place to safeguard the gear teeth on the outer ring, which is anchored by the lower structure using threaded bolts.

Fig 3

The pinion is connected to the upper structure, supported by the outer ring. Placing the gear on the inner ring shields it from harsh external conditions. Shown: threaded bolt arrangement.

Fig 4

The pinion attaches to the lower structure, supporting the inner ring. The geared outer race holds up the upper structure. Through bolts secure the inner ring, while threaded bolts secure the outer ring.

Explore the different bearing styles and cross-sections. The following figure highlights some of the slewing bearing designs offered by LILY Bearing.

The RK Series are available in geared and non-geared variants ranging from 20” to 47” OD, supporting up to 141,000 ft-lbs moment, 175,000 lbs thrust, and 35,000 lbs radial loads.

MT Series are available up to 240” OD with moment capacities up to 10,000,000 ft-lbs, thrust up to 6,000,000 lbs, and radial loads up to 1,300,000 lbs.

XR Series are available in sizes up to 315” OD, in internal, external, or non-geared versions.

TR Series are available in sizes up to 315” OD with moment capacities exceeding 50,000,000 ft-lbs, thrust over 18,000,000 lbs, and radial loads above 4,000,000 lbs, in internal, external, or non-geared configurations.

Make a preliminary selection by comparing operating bearing forces, including the service factor, to the bearing's rating curve:

Contact the manufacturer if the slewing bearing doesn't meet these criteria.

Bearing's Rating Curve

Ensure the gear size and quality meet application requirements by verifying the following:

Module, Tooth Count, and Face Width: Match the gear dimensions to the load and torque demands.

Verify that the chosen slewing ring meets all load, speed, accuracy, and environmental requirements before proceeding.

| Properties | 42CrMo4 (1.7225) | 50Mn GB/T 699 | 42CrMo GB/T 3077 |

| Chemical composition (%) |

C:0.38-0.45 Si:≤0.40 Mn:0.60-0.90 P:≤0.025 S:≤0.035 Cr:0.90-1.20 Mo:0.15-0.30 |

C:0.48-0.56 Si:0.17-0.37 Mn:0.70-1.00 P:≤0.035 S:≤0.035 Cr:≤0.25 Ni:≤0.30 Cu:≤0.25 |

C:0.38-0.45 Si:0.17-0.37 Mn:0.50-0.80 P:≤0.030 S:≤0.030 Cr:0.90-1.20 Mo:0.15-0.25 |

| Mechanical properties |

Yield strength:≥930 MPa Tensile Strength:≥1080 MPa Elongation:≥12% Hardness:≤217HB |

Yield strength:≥390 MPa Tensile Strength:≥645 MPa Elongation:≥13% Hardness:≤217HB |

Yield strength:≥930 MPa Tensile Strength:≥1080 MPa Elongation:≥12% Hardness:≤217HB |

| Properties | 100Cr6 EN ISO 683-17:2000 | GCr15-GB/T 18254 |

| Chemical composition (%) |

C:0.93-1.05 Si:0.15-0.35 Mn:0.25-0.45 P:≤0.025 S:≤0.015 Cr:1.35-1.60 Ni: - Mo:≤0.10 |

C:0.95-1.05 Cu:≤0.25 Si:0.15-0.35 O:≤0.0012 Mn:0.25-0.45 Ti:≤0.005 P:≤0.025 Al:≤0.05 S:≤0.02 As:≤0.04 Cr:≤1.40-1.65 As+Sn+Sb:≤0.075 Ni:≤0.25 Pb:≤0.002 Mo:≤0.10 |

| Mechanical properties |

Yield strength:≥590 MPa Tensile Strength:≥830-1130 MPa Elongation:≥10% Diameter:30 mm Anneal to achieve spheroidized carbides:≤207HBW Anneal to achieve spheroidized carbides and cold worked:≤241HBW |

Yield strength:≥518.42 MPa Tensile Strength:≥861.3 MPa Elongation:≥27.95% Spheroidzing annealing hardness:179-207 HBW Softening annealing hardness:≤245 HBW |

Heat treatment is used to enhance the hardness and wear resistance of slewing bearings. Lily Bearing uses selective hardening to achieve HRc 50-60, preventing failure modes like abrasive wear, fatigue, and corrosion.

LILY Bearing ensures structural integrity by considering critical design factors to accommodate various loads without failure. Bearings are customized for specific applications, addressing unique engineering challenges to deliver optimal performance.

The assembly follows strict quality standards to ensure each component meets requirements. LILY slewing bearings undergo load and durability testing to verify they meet performance standards.

LILY Bearing recommends No. 2 lithium ester grease (Great Wall) for temperatures from -20°C to 120°C, ensuring smooth operation and corrosion resistance. Choose grease based on temperature, load, and environment to prevent wear and failure.

Choosing the right slewing ring is crucial. This blog post "How Do I Choose a Slewing Bearing?" guides you through load requirements, gear design, and mounting arrangements. For personalized advice and quality slewing rings, contact LILY Bearing today!

Bearings ensure the smooth operation and long life of mechanical components. Kaydon Bearings are known for their high performance and versatility....

Bearings are often unseen, yet they play a fundamental role in ensuring the smooth and efficient functioning of countless machines, devices, and...

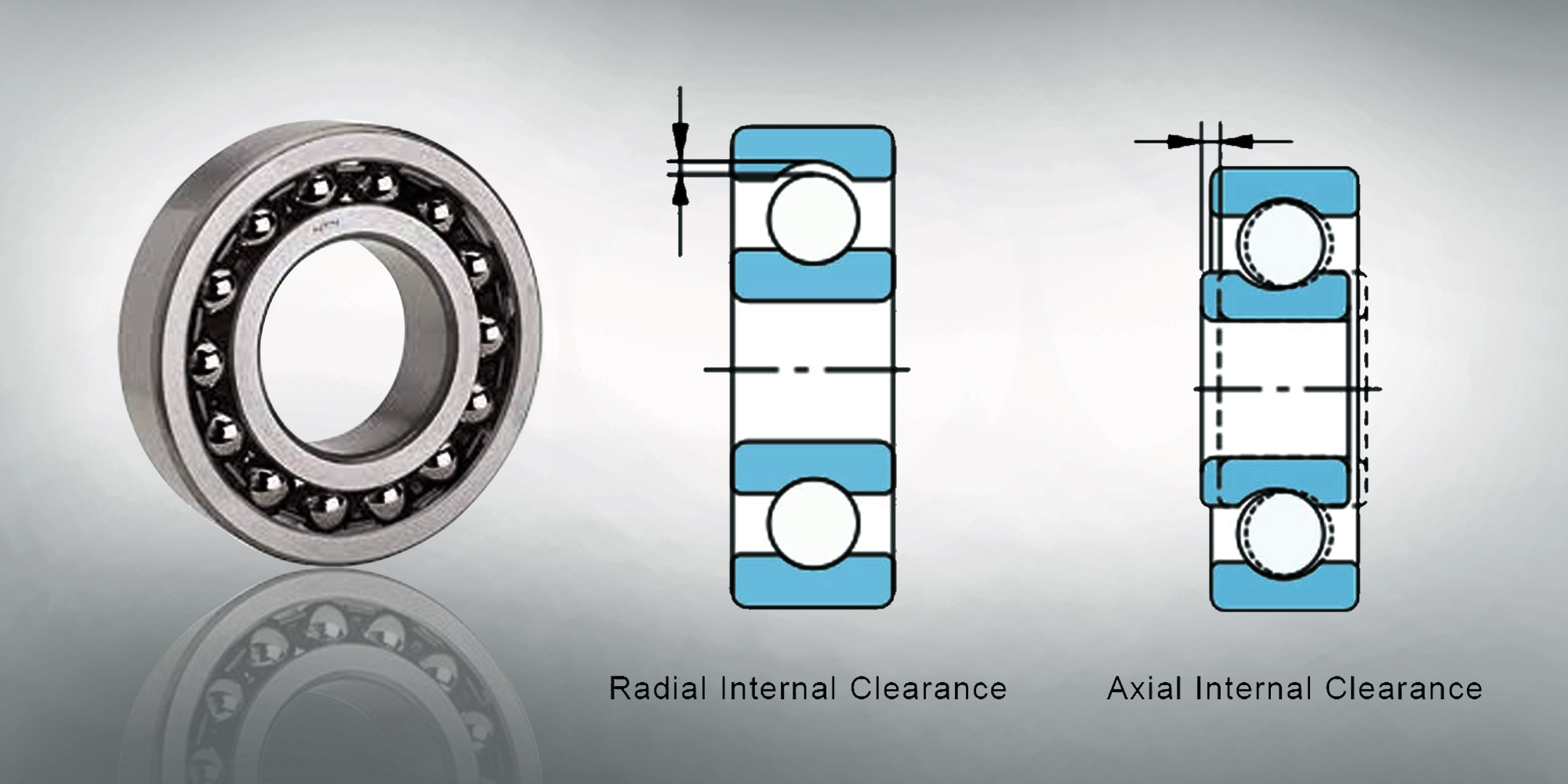

Bearing clearances, whether in ball bearings like the 608 Bearing or roller bearings, play a crucial role in the intricate world of precision...