The Role of Dental Bearings in Cleaning Dental Handpieces

Dental handpieces play an important role in dental procedures. Dental bearings ensure precise performance, extend the handpiece's lifespan, enhance...

Ball bearings are bearings that use spherical balls to keep the inner and outer races apart. They reduce friction between moving parts, enabling smoother rotation of shafts and components.

Ball bearings are important for making machines work better, last longer, and be more reliable in industrial settings.

Selecting the right ball bearing based on load, speed, materials, and working conditions is essential. This choice can greatly improve machine performance and longevity. This careful selection also helps make the machines last longer.

Reducing friction makes machines use energy more efficiently by lowering resistance, which means they need less power to run.

It also creates less heat, preventing energy loss and overheating. This leads to efficient operation and enhanced performance. It also reduces wear on parts, making them last longer and needing fewer replacements. Overall, less friction helps machines work better and use energy more effectively.

Ball bearings handle weight placed across the shaft. They use their round balls to evenly spread the load between the inner and outer rings (races). When a load is applied, the balls roll, which reduces friction and allows smooth movement.

The design of the races keeps the balls in place and ensures stability, helping the bearing handle the load without slipping. Overall, this setup allows ball bearings to effectively manage loads while keeping machinery running smoothly.

Ball bearings handle axial loads, which are forces that push along the shaft, to keep things stable and running smoothly.

They are designed to support these loads by ensuring the rolling balls stay in contact with the races, spreading the load evenly. This helps prevent misalignment and reduces wear on the parts. By managing axial loads well, ball bearings make machines more reliable and help them last longer.

Ball bearings help prevent wear by managing loads effectively. They evenly distribute the force across the rolling balls, which reduces stress on the parts.

This helps minimize friction and wear, keeping the components in good condition and extending their lifespan. By handling loads properly, ball bearings ensure smoother operation and less damage over time.

Ball bearings help reduce vibrations, which extends the life of equipment. By reducing friction and allowing smooth movement, they absorb vibrations that could otherwise cause damage.

This cushioning effect prevents too much shaking and stress on parts, lowering the risk of failure. In short, ball bearings keep machines running smoothly and lasting longer.

Ball bearings manage heat in fast-moving machines by reducing friction. The rolling balls create less contact, which helps prevent overheating.

Some bearings use materials like ceramics that handle heat better. Lubrication also helps by reducing friction and carrying heat away. In some cases, special designs allow more airflow to keep the bearings cool during high-speed use.

Ball bearings keep automated systems accurate by reducing friction and allowing smooth, exact movement. They prevent parts from slipping or vibrating, which is important for machines to work correctly. By keeping everything aligned and working smoothly, ball bearings ensure automated systems stay accurate and efficient.

Ball bearings stop wobbling and keep things aligned by supporting rotating parts smoothly. The round balls inside roll between the inner and outer rings, keeping the shaft centered and balanced.

This rolling action reduces friction and makes sure everything spins evenly, preventing side-to-side movement. By keeping everything aligned, ball bearings help machines run smoothly and accurately.

Self-lubrication reduces the need for regular oiling by using special materials that release lubricant gradually. This creates a thin layer of grease between moving parts, which lowers friction and helps them move smoothly.

As a result, machines require less maintenance, saving time and money. With less friction, parts wear out less quickly, making equipment last longer and work better.

Durable ball bearings help reduce breakdowns by lasting longer and handling tough conditions. Because they are made with strong materials, they can withstand wear and tear better than weaker bearings. This means they need fewer repairs and replacements.

Reducing costs related to machine downtime and repairs is important for businesses. Using durable ball bearings helps prevent these breakdowns, so machines run smoothly for longer. This means less time and money spent on repairs, leading to overall savings for the company. Keeping machines running efficiently helps improve productivity and reduce costs.

Steel bearings are strong and can handle heavy loads effectively, making them ideal for demanding applications. However, they are less resistant to heat, which means they may not perform as well in high-temperature environments.

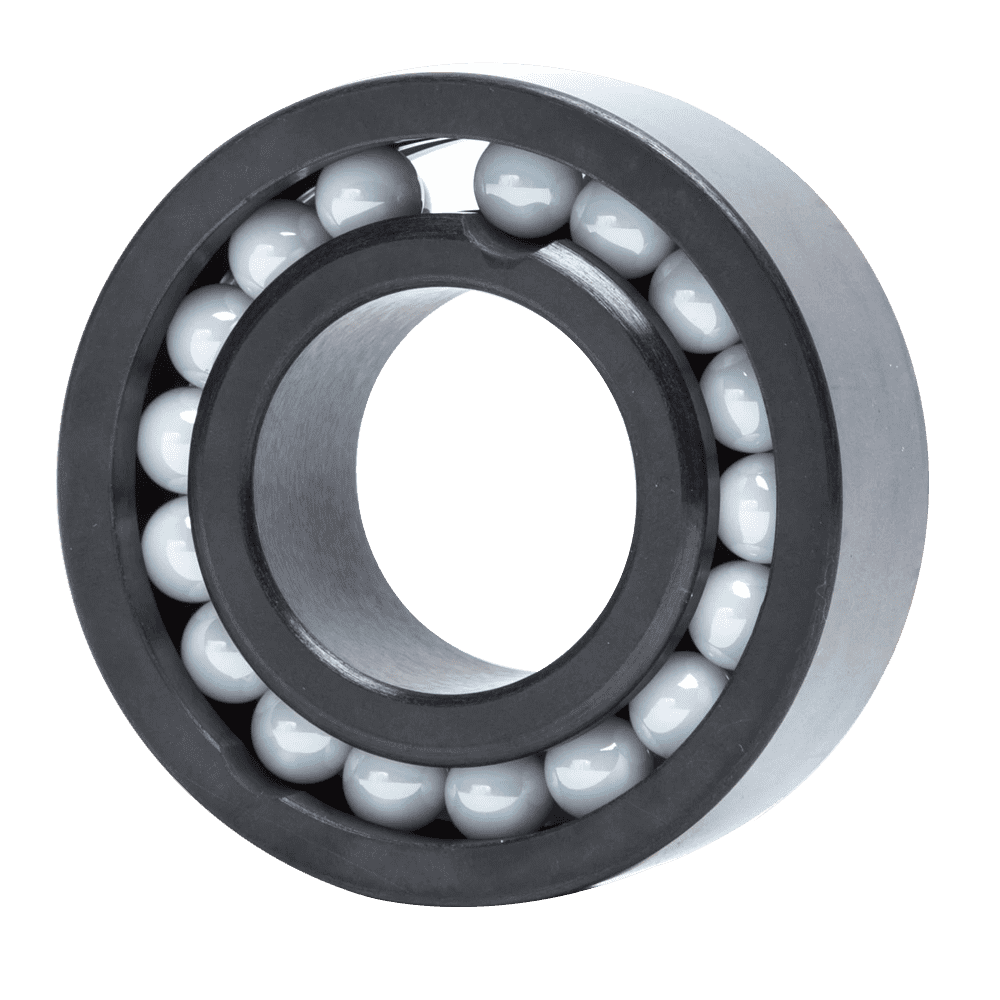

Ceramic bearings are lightweight and resistant to heat, making them great for high-speed use. Their special features help them run smoothly and reduce friction, improving performance and reliability in tough conditions.

When picking the right material for ball bearings, think about the weight they need to support and how fast they will go. Also, consider the environment where they will be used. Strong materials like steel are ideal for handling heavy loads. In contrast, lightweight ceramics are better suited for high speeds, while corrosion-resistant options work best in harsh conditions.

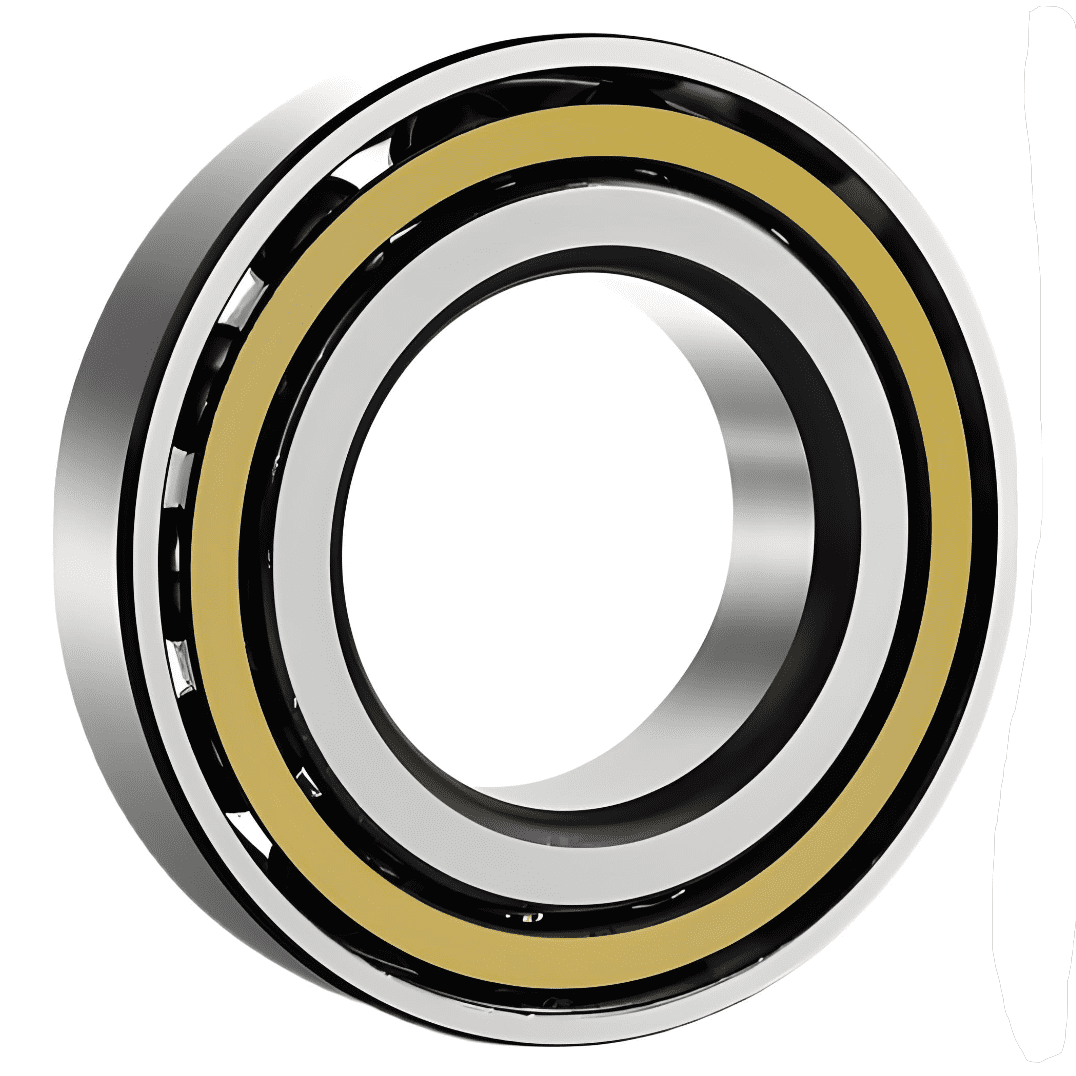

Hybrid bearings combine ceramic and steel materials for better overall performance. The ceramic balls are lightweight and heat-resistant, while the steel races provide strength and durability.

This mix reduces friction and improves speed while still handling heavy loads well. They are perfect for specialized applications like aerospace, motorsports, and high-speed machines.

Ball bearings make machines work better by allowing smooth movement and reducing friction between parts. This helps machines run more efficiently and prevents wear, which makes them last longer. By reducing energy loss and maintaining proper alignment, ball bearings help machines operate reliably. This leads to increased productivity and lower maintenance costs.

When choosing the best ball bearings for your machinery, think about what you need for your specific application. Consider things like how much weight they need to carry, the speed they will run at, and the conditions they will be in.

Choose materials that fit these needs, like steel for heavy loads or ceramic for high speeds. Also, look for features like seals for protection and good lubrication for easy maintenance.

Dental handpieces play an important role in dental procedures. Dental bearings ensure precise performance, extend the handpiece's lifespan, enhance...

Dental bearings are important for making dental tools work smoothly. They help parts like drills and turbines spin, making procedures more precise...

Curious about maintaining ceramic bearings? Questions like “What makes ceramic bearings better?”, "What can I use to clean ceramic bearings?" or...