How to Choose the Right Polyurethane Rollers

In the realm of industrial operations, selecting the perfect parts is crucial. They can significantly impact efficiency, performance, and the overall...

Polyurethane rollers, or poly rollers, are vital in many industries because they are durable, flexible, and resistant to wear and chemicals.

In this blog, we will guide you to explore how poly rollers are made throughout the process from core fabrication to quality testing, and explain why they are so important.

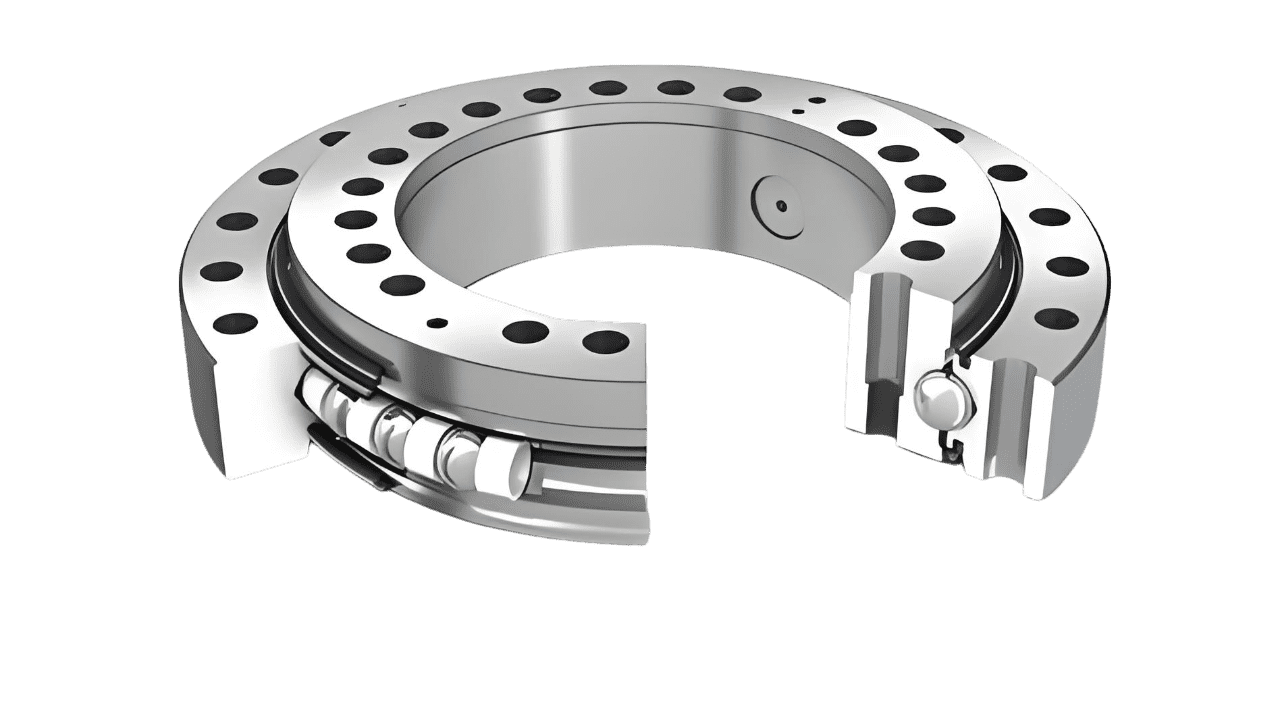

Polyurethane rollers, also called polyurethane rollers with bearings, are cylindrical parts used in many industrial applications. They have a steel core covered with a layer of polyurethane, which acts as a protective and functional coating, enhancing the roller's performance.

Polyurethane drive rollers are valued for their durability, flexibility, and resistance to wear and chemicals. With these features, the rollers are able to handle heavy use, adapt to different pressures, and resist damage from various substances, which make them reliable and efficient in tough environments.

Polyurethane rollers are utilized across various industries, including:

Polyurethane rollers are used in many manufacturing processes for tasks such as:

Secondary processes for urethane roller cores typically include:

Types of Imbalance

Static and dynamic imbalances can both harm roller performance, but in different ways. Static imbalance causes wobbling due to uneven weight distribution around the roller's axis. Dynamic imbalance leads to irregular rotation and complex vibrations because of uneven mass distribution along the roller's length. Both types of imbalance can reduce performance and lifespan of the roller.

Balancing Process

Dynamic balancing uses a computer-controlled system to detect and correct imbalances in the following steps:

Chemical Composition

Polyurethane is crafted from components like polyols, diisocyanates, curatives, and additives. They’re tailored to achieve specific properties for various applications.

Mixing Methods

There are three main mixing methods for polyurethane blending:

Chemical Bonding: Bonding agents help polyurethane stick firmly to the roller core, usually metal. First, a primer cleans and activates the core surface. Then, an adhesive creates a strong bond with the polyurethane, ensuring it stays attached during use.

Building Methods

These buiding methods are chosen based on cost, complexity, and production needs.

Curing stabilizes elastomers like polyurethane. Heat or room temperature initiates cross-linking between molecules.

In heat curing, high temperatures are used to speed up the process, creating strong bonds that make the material resistant to heat, cold, and solvents. Room temperature curing uses chemicals to achieve the same effect without heating.

Post-curing adds an extra step after the initial curing. This further improves the elastomer's strength, durability, and resistance to aging. It ensures the material performs well under long-term stress and harsh conditions.

After curing, polyurethane rolls need to cool to solidify and stabilize. This can be done gradually at room temperature or with controlled cooling systems. Once cooled, the rollers are carefully removed from the mold, maintaining their shape and properties.

These tests give a deeper insight into how the rollers perform under extreme conditions.

This blog guides you to explore how polyurethane rollers are made. Polyurethane rollers are made through careful core fabrication, coating, curing, machining, and thorough quality testing. Quality control ensures that each roller is durable and performs well, even in tough conditions.

We use eco-friendly materials and efficient processes to minimize environmental impact. Choose our high-quality polyurethane rollers for reliable and efficient operations. Contact us today to learn more about how our products can benefit your business.

In the realm of industrial operations, selecting the perfect parts is crucial. They can significantly impact efficiency, performance, and the overall...

Industrial rollers are the unsung heroes of manufacturing and various other sectors, playing a pivotal role in ensuring smooth operations, precise...

In industrial settings, rollers are key to keeping machinery and processes running smoothly. Polythane and rubber are the top materials used for...